Rockwell Automation 20G PowerFlex 750-Series AC Drives User Manual

Page 272

272

Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Chapter 4

Motor Control

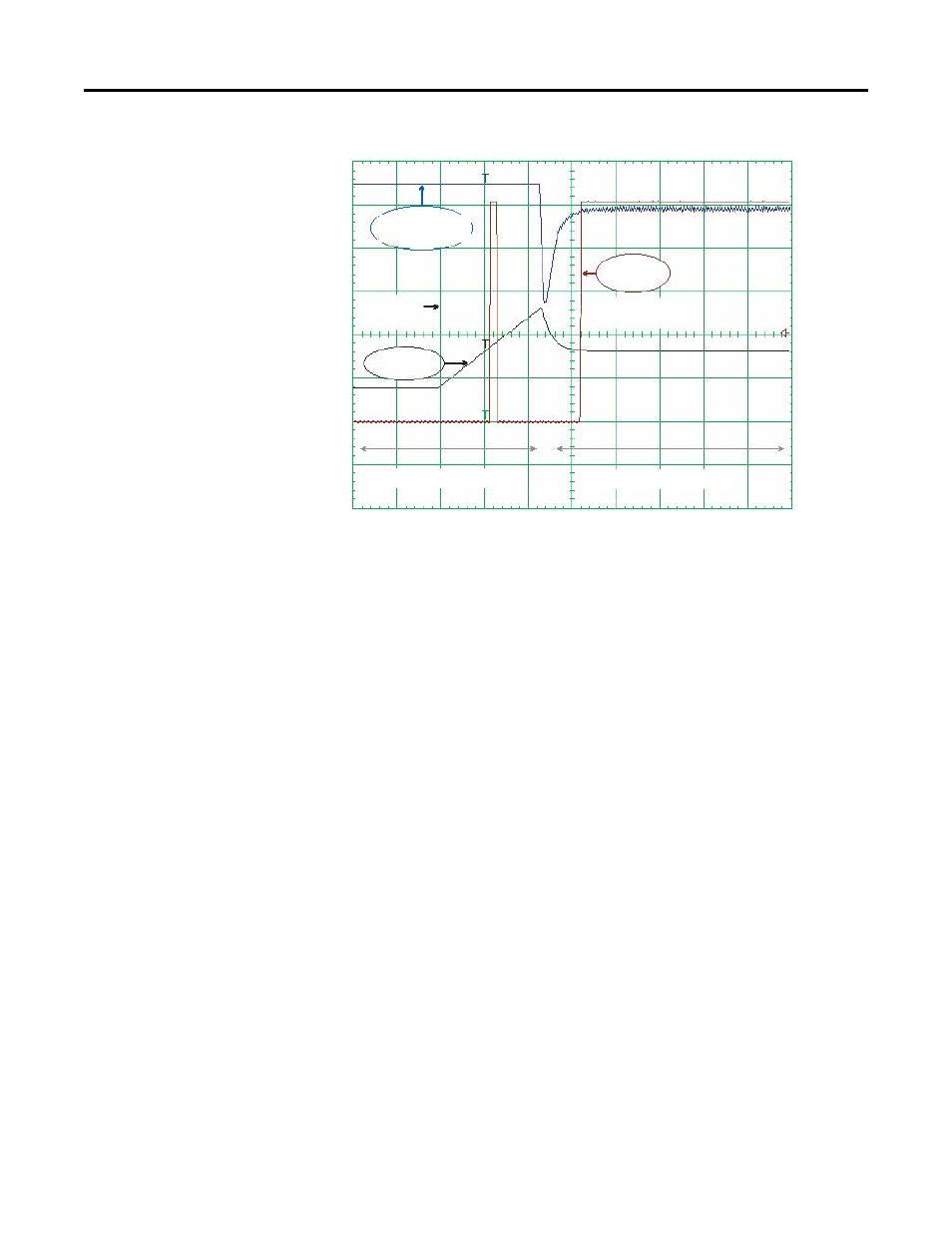

Figure 33 - Minimum Torque Speed without SLAT

Or

•

The speed error becomes negative (the speed feedback becomes greater

than the speed reference). This would force the control into speed

regulator mode, a condition called Forced Speed Mode FSM.

By forcing the drive to enter speed mode FSM, the transition occurs earlier than

it would have if the reaction was triggered at the very point that the torque

reference value in speed mode is mathematically less than the value in torque

mode, generally resulting in less velocity overshoot.

P314 [SLAT Err Stpt] and P315 [SLAT Dwell Time] allow setting some

hysteresis for turning off the forced speed mode. They are set to 0 as default so

that there is no hysteresis. In SLAT minimum mode, [SLAT Err Stpt] sets how

much less the speed feedback should be than the speed reference before turning

off the forced speed mode. The SLAT dwell time sets how long the speed error

must exceed the SLAT error set point before turning off the forced speed mode.

At the time that the drive switches from torque mode to forced speed mode, the

speed regulator output is loaded with the internal motor torque reference to

create a smooth transition. In order for the drive to switch from speed mode back

to torque mode, forced speed mode (if active) must first be turned off. Forced

speed mode will turn off when the speed error is greater than the SLAT error set

point for the SLAT dwell time.

With default parameter settings, this will occur when the speed error becomes

positive.

When forced speed mode is off, the drive will switch back to Torque mode when

the speed regulator output becomes greater than the torque reference.

Internal Torque

Command

Load Step

(Decreased)

Speed

Feedback

At Speed

Relay

Torque Regulator

Speed Regulator