Rockwell Automation 20P PowerFlex Digital DC Drive User Manual

Page 73

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

73

Installation and Wiring

Chapter 1

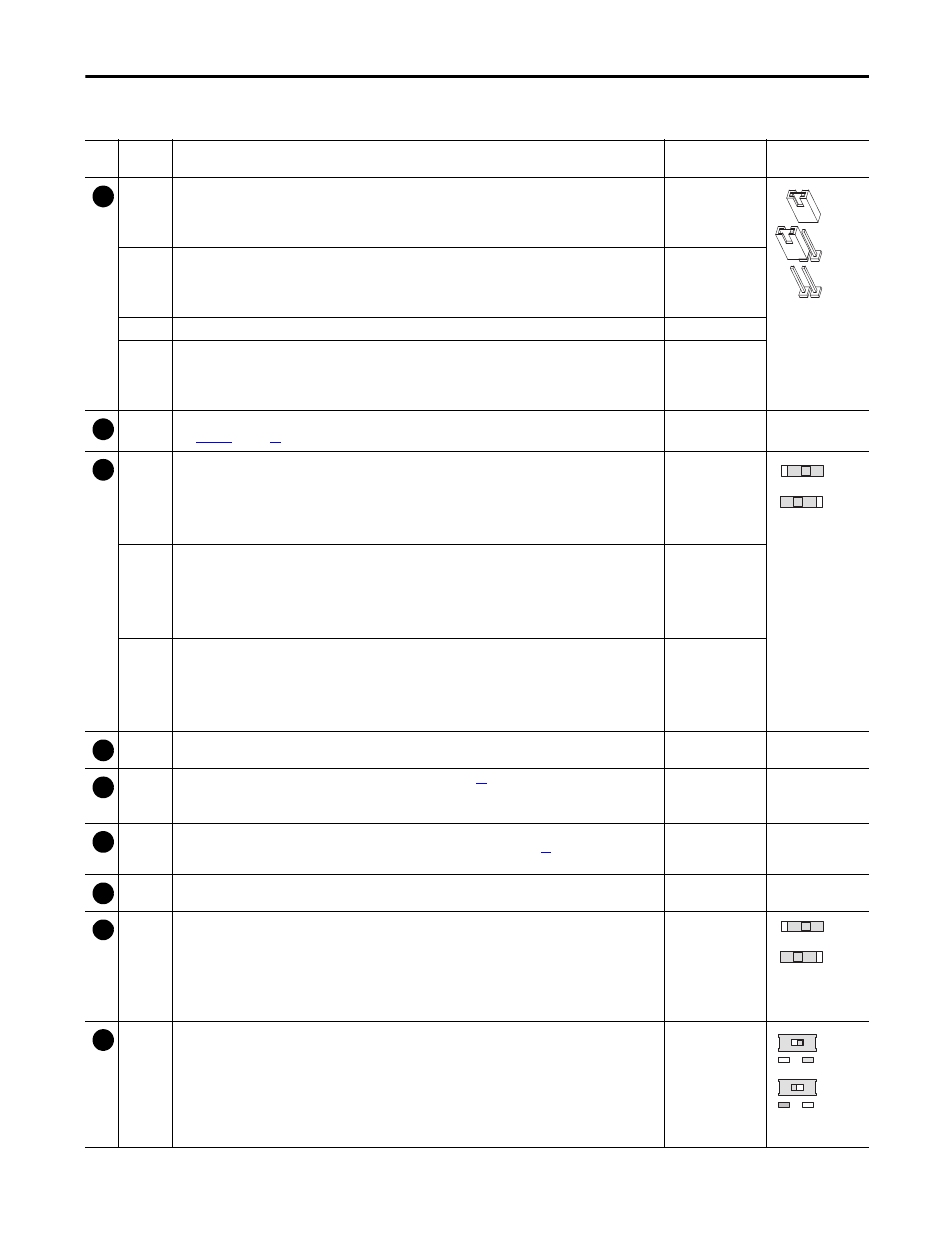

Table 26 - Control Circuit Board Jumper and DIP Switch Settings

ID

Jumper/

Switch

Function

Factory Default

Example

S0

For factory boot flashing only. Leave set to the factory setting.

Jumper Off

Jumper On

Firmware boot

Jumper Off

Normal function

S1

For factory boot flashing only. Leave set to the factory setting.

Jumper Off

Jumper On

Write firmware boot code

Jumper Off

Boot code on flash is protected

S2

Not used. Leave set to the factory setting.

Jumper Off

S3

For factory boot flashing only. Leave set to the factory setting.

Jumper Off

Jumper On

Reset

Jumper Off

Normal function

S4

Configures the input voltage of the DC analog tachometer.

See

on page

for configuration.

90V

–

S9

Configures the input signal of Analog Input 1 (terminals 1 and 2):

On

Off Position

0…20 mA / 4…20 mA

On Position

0…10V / ±10V

Note: The input signal type must also be programmed accordingly using Par 71 [Anlg In1 Config].

S10

Configures the input signal of Analog Input 2 (terminal 3 and 4):

On

Off Position

0…20 mA / 4…20 mA

On Position

0…10V / ±10V

Note: The input signal type must also be programmed accordingly using Par 76 [Anlg In2 Config].

S11

Configures the input signal of Analog Input 3 (terminals 5 and 6):

On

Off Position

0…20 mA / 4…20 mA

On Position

0…10V / ±10V

Note: The input signal type must also be programmed accordingly using Par 81 [Anlg In3 Config].

S12

Not used. Leave set to the factory setting.

Off

–

S14

Field current resistors setting, see Field Current Configuration on page

.

The value selected with switch S14 must be entered in Par 374 [Drv Fld Brdg Cur] when the drive is

commissioned. For permanent magnet motor applications, leave set to the factory default settings.

Minimum field

current rating based

on drive size.

–

S15

Configuration of the control circuit board to the appropriate drive size. Leave set to the factory setting, unless the

control board has been supplied as a spare part. See DIP Switch S15 Settings on page

74

for switch configuration

based on drive current rating code.

Armature current

based on drive size.

–

S18

Not used. Leave set to the factory setting.

Off

–

S20

Monitoring of the Z channel of the Digital Encoder on connector XE2:

On

Off Position

Z channel monitored

On Position

Z channel not monitored

The S20 setting should match the value selected in Par 652 [Encoder Err Chk] (for example, if

S20 = “Off”, then Par 652 = 1 “Enabled”).

S21

Encoder power supply voltage and input selection:

This switch setting determines both the power supply (input) and feedback level (output) voltage of the

connected encoder.

Note: When control power is supplied to the drive, the appropriate LED lights to indicate the selection of the

switch.

12…5 V

ENC_5

+5 V encoder (+2.5…5.4V input range)

ENC_12

+12…15 V encoder (+5.4V…15.2V input range)

1

= ON

= OFF

=OFF

2

3

= ON

= OFF

4

5

6

7

8

= ON

= OFF

9

= 12-15V

= 5V

ENC_5 ENC_12

ENC_5 ENC_12