Dc contactor crimp lug kit specifications, Dc contactor crimp lug kit specifications on pag – Rockwell Automation 20P PowerFlex Digital DC Drive User Manual

Page 244

244

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Appendix A

Supplemental Drive Information

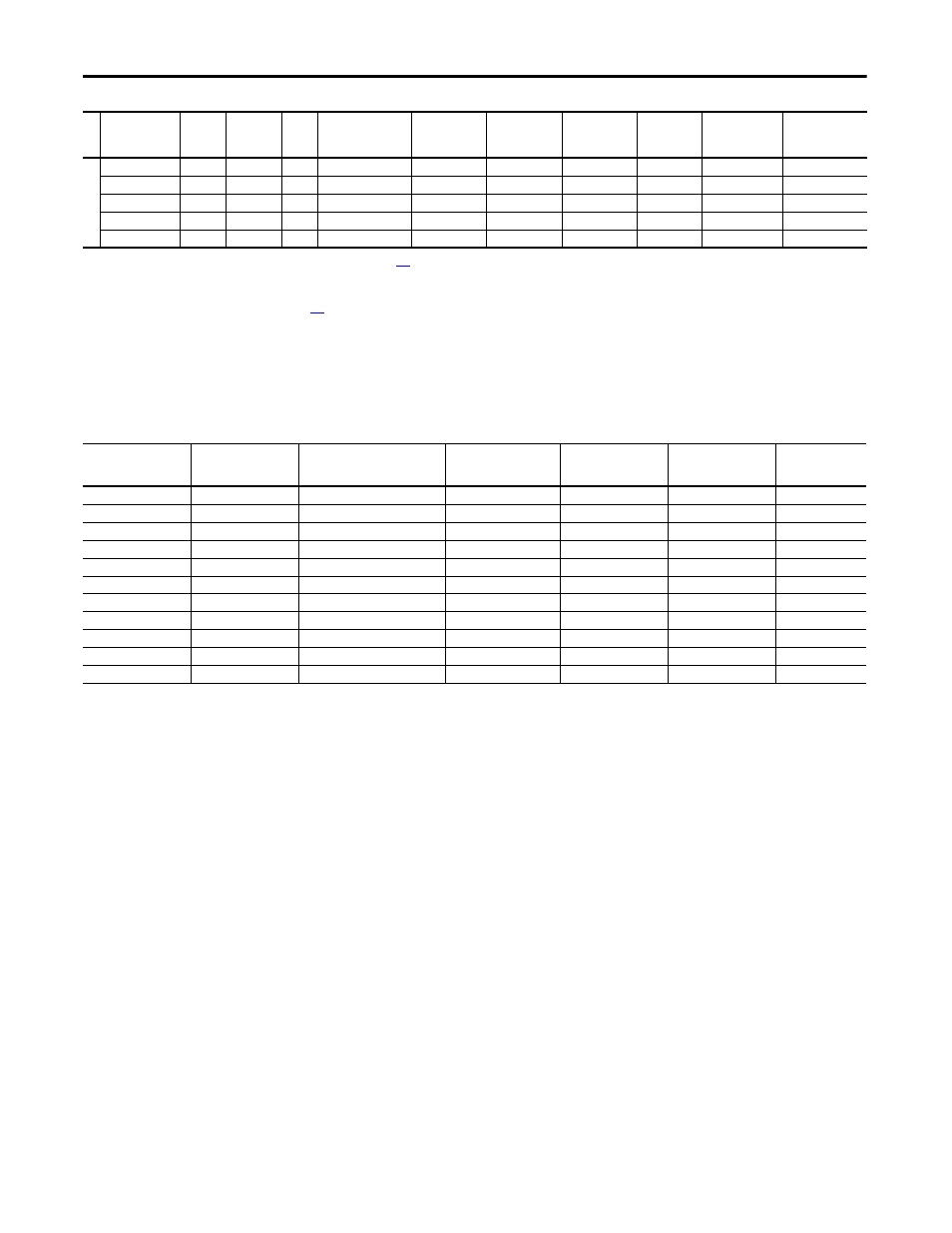

DC Contactor Crimp Lug Kit

Specifications

Use the information provided in the table below to assist you in ordering the

correct Lug kit for your application.

D 800

830

678.1

500

(2)

500

0.463

6338

–

(1)

(5)

960

996

813.7

600

(2)

500

0.322

6221

–

(1)

(5)

1K1

1162

949.4

700

(2)

500

0.322

6221

–

(1)

(5)

1K3

1328

1085.0

800

(2)

500

0.255

5718

–

(1)

(5)

1K4

1494

1220.6

900

(2)

500

0.255

5718

–

(1)

(5)

(1) See Alternate Dynamic Brake Resistor Kits and DC Output Contactors on page

.

(2) No Dynamic Brake Resistor kit available for this drive rating - must be sourced locally.

(3) Coil voltage = 115V AC, 50/60Hz.

(4) See DC Contactor Crimp Lug Kit Specifications on page

for more information.

(5) Wire and Lug size dependant on enclosure dimensions and local codes.

Fram

e Drive Current

Rating Code

DC

Amps

AC Line

Amps

Hp

Dynamic Brake

Resistor Kit Cat.

No.

Armature

Voltage

(Volts)

DB Resistor

Size (ohms)

DB Resistor

Size (Watts)

Brake Amps

Required

DC Loop

Contactor Cat.

No.

(3)

DC Contactor

Crimp Lugs Cat.

No.

(4)

Rated Motor Armature

Current

(1)

A DC

DC Contactor Rating

A DC

Armature Conductor Size

(2)

AWG

DB Conductor Size

(3)

AWG

Armature Conductor

Crimp Lug Hole Size

DB Conductor Crimp

Lug Hole Size

Lug Kit Catalog

Number

4.1…35

56

8

8

#10

#10

1370-LG40

45…52

56

6

8

#10

#10

1370-LG52

55

56

4

8

#10

#10

1370-LG56

60…86

110

2

6

0.25 in.

0.25 in.

1370-LG92

100…110

110

1/0

4

0.25 in.

0.25 in.

1370-LG110

129

180

2/0

2

0.3125 in.

0.3125 in.

1370-LG140

146

180

3/0

2

0.3125 in.

0.3125 in.

1370-LG160

147…167

180

4/0

2

0.3125 in.

0.3125 in.

1370-LG180

207…218

280

300MCM

1/0

0.5 in.

0.375 in.

1370-LG228

250…265

280

400MCM

2/0

0.5 in.

0.375 in.

1370-LG268

266…280

280

500MCM

3/0

0.5 in.

0.375 in.

1370-LG280

(1) The Rated Motor Armature Current is taken directly from the motor nameplate or motor data. The current listed in this column is the maximum current allowed for the Armature Conductor Size (column

3) and the DC Contactor Rating (column 2).

(2) The armature conductors are sized by multiplying the Rated Motor Armature Current by 1.25 as provided for in NEC 420-22 (1987). The DC lug ratings are determined from NEC Table 310-16 (1987) for

copper conductors, insulation temperature rated at 75° C (167° F) at an ambient temperature of 30° C (86° F). If conditions are other than shown in NEC Table 310-16, then refer to application codes.

(3) The dynamic braking (DB) conductors are sized as in footnote 2 above, but at half ampacity due to the short time duration of current flow in these conductors, and has been sized to satisfy NEMA Standard

ICS 3-302.62 - Dynamic Braking. If the load inertia is larger than that of the motor, calculations must be made to determine correct conductor sizing and DB resistor wattage per NEMA Standard ICS 3-

302.62.