Rockwell Automation 20P PowerFlex Digital DC Drive User Manual

Page 152

152

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Chapter 3

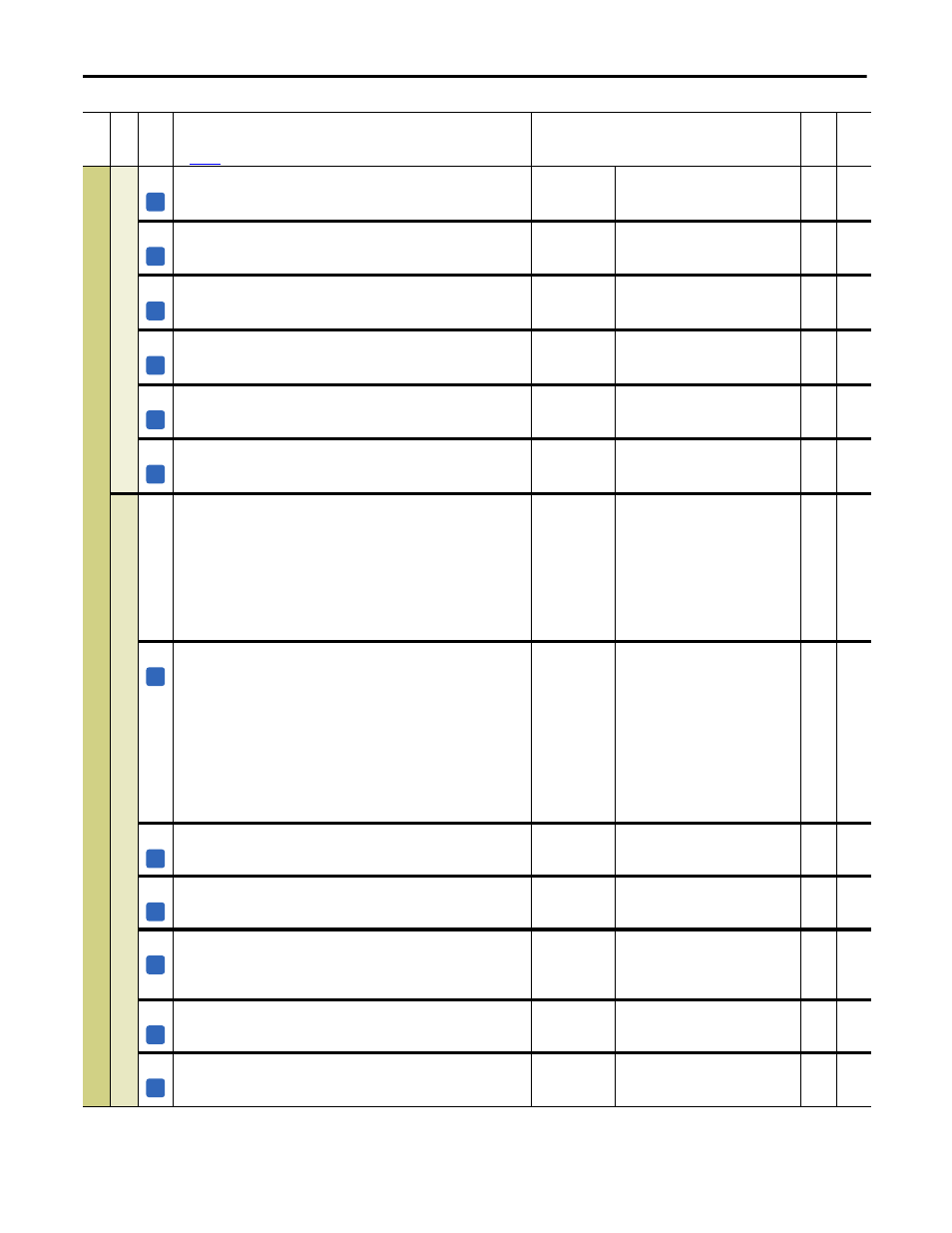

Programming and Parameters

APPL

IC

AT

IONS

PD

Co

nt

ro

l

768

[PD Prop Gain 1]

First proportional gain of the block PD. The value specified in this field depends on

the enabling and configuration of Par 181 [Adaptive Spd En].

Default:

Min/Max:

10.00

0.00 / 100.00

Real

181

770

[Enable PD]

Enables/disables the PD portion of the PID regulator.

Note: This parameter can be assigned to a digital input.

Default:

Options:

0 =

0 =

1 =

“Disabled”

“Disabled”

“Enabled”

16-bit

Int

788

[PD Prop Gain 2]

Second proportional gain of the block PD. The value specified in this field depends

on the enabling and configuration of Par 181 [Adaptive Spd En].

Default:

Min/Max:

10.0

0.0 / 100.0

Real

181

789

[PD Deriv Gain 2]

Second derivative gain of the PD block. The value specified in this field depends on

the enabling and configuration of Par 181 [Adaptive Spd En].

Default:

Min/Max:

10.0

0.0 / 100.0

Real

181

790

[PD Prop Gain 3]

Third proportional gain of the block PD. The value specified in this field depends on

the enabling and configuration of Par 181 [Adaptive Spd En].

Default:

Min/Max:

10.0

0.0 / 100.0

Real

181

791

[PD Deriv Gain 3]

Third derivative gain of the PD block. The value specified in this field depends on

the enabling and configuration of Par 181 [Adaptive Spd En].

Default:

Min/Max:

1.00

0.00 / 100.00

Real

181

PID

Co

nt

ro

l

418

[Real FF PID]

Represents the feed–forward value which has been recalculated according to the

PI correction. It will be calculated with the following formula:

Par 418 [Real FF PID] = (Par 758 [Feed Fwd PID] / 1000 ) x Par 771 [PI Output]

When either the negative or positive limit of this parameter has been reached,

further increases in the value of Par 771 [PI Output] will be blocked in order to

avoid undesirable saturation of the PID regulator. For example:

When Par 758 [Feed Fwd PID] = +8000, the positive limit of Par 771 [PI Output]

will be automatically set at 10000 / ( 8000 / 1000 ) = 1250.

Default:

Min/Max:

Read Only

–/+10000

16-bit

Int

758,

771

757

[PID Clamp]

The PID “clamp” allows a smooth tension setting of a controlled system winder/

unwinder when the calculation of the initial diameter function cannot be used.

• When enabling the drive, the dancer is at the lowest point of its full scale. In this

case, with Par 759 [PID Error] at its maximum value, the motor could accelerate

too fast to properly configure the dancer for its central operating position. By

setting the value of Par 757 [PID Clamp] sufficiently low. e.g, = 1000, when the

drive starts and Par 770 [Enable PD] = 1 “Enable”, the value of Par 759 [PID

Error] is limited to 1000 until the signal coming from the dancer (via Par 763

[PID Feedback]) goes above the value in this field. Then, the value of [PID

Clamp] is automatically returned to its maximum value of 10000. The PID clamp

is kept at 10000 until the drive stops or Par 770 [Enable PD] = 0 “Disabled”.

Default:

Min/Max:

10000

0 / 10000

16-bit

Int

759,

763,

770

758

[Feed Fwd PID]

Feedback from the transducer position (dancer) or tension.

Default:

Min/Max:

Read Only

–/+10000

16-bit

Int

759

[PID Error]

Error value input to the PID function (output of the PID Clamp block).

Default:

Min/Max:

Read Only

–/+10000

16-bit

Int

760

[PID Setpoint 0]

First offset value added to Par 763 [PID Feedback]. This parameter can be assigned

to an analog input, for example, for the tension setting when a load cell must be

used as feedback.

Default:

Min/Max:

0

–/+10000

16-bit

Int

763

761

[PID Setpoint 1]

Second offset value added to Par 763 [PID Feedback].

Default:

Min/Max:

0

–/+10000

16-bit

Int

763

762

[PID Setpoint Sel]

Selects the offset value added to Par 763 [PID Feedback]. This parameter can be

assigned to a digital input.

Default:

Options:

0 =

0 =

1 =

“Setpoint 0”

“Setpoint 0”

“Setpoint 1”

16-bit

Int

763

Fil

e

Gr

oup

No

.

Parameter Name & Description

See

page 110

for symbol descriptions

Values

Da

ta

T

yp

e

Rela

ted

A

A

A

A

A

A

A

A

A

A

A

A