Rockwell Automation 20P PowerFlex Digital DC Drive User Manual

Page 160

160

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Chapter 3

Programming and Parameters

APPL

IC

AT

IONS

W

inder F

un

cti

ons

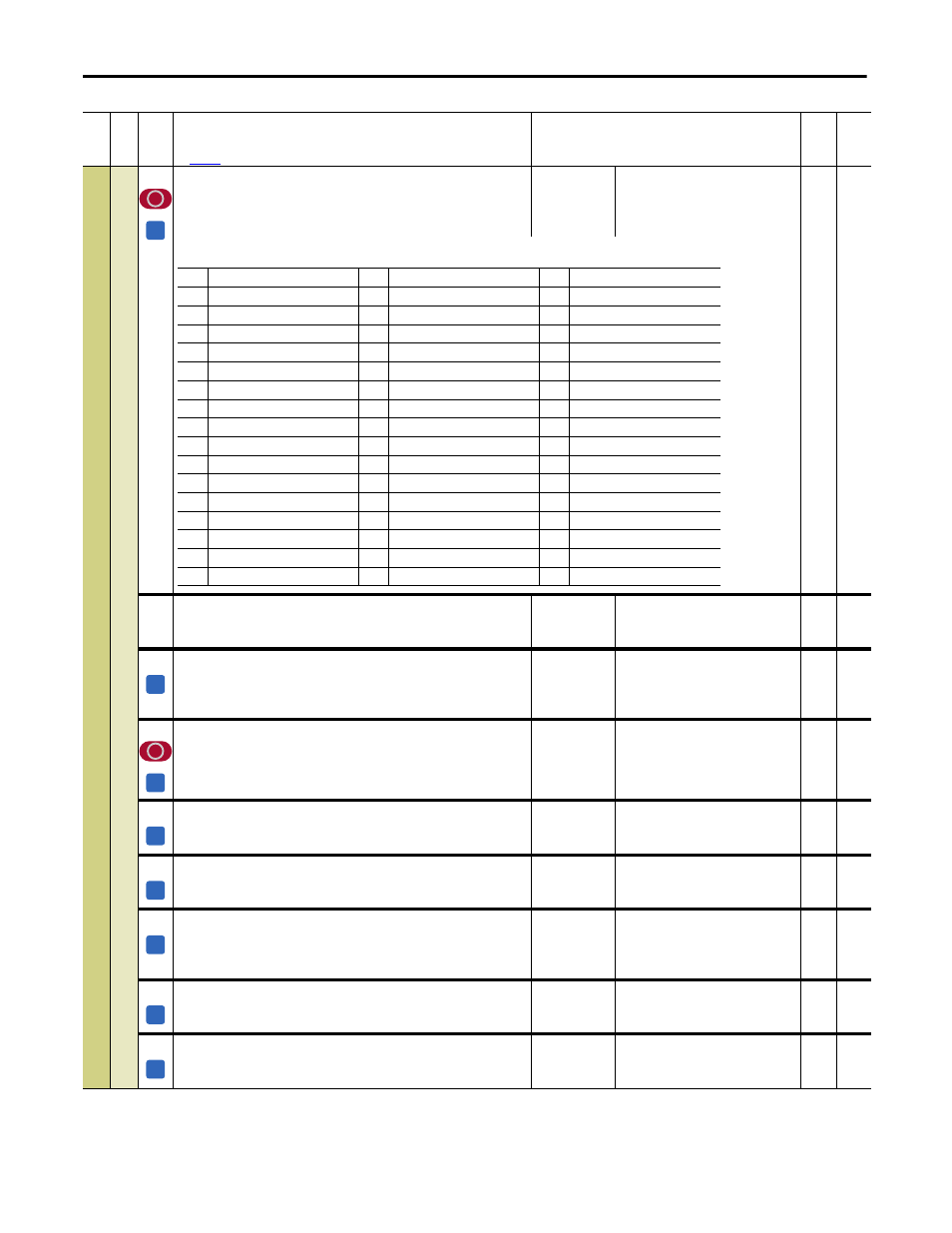

1210 [W Target]

Number of the parameter to which the winder speed reference is written.

Notes: Added options 0…47 for firmware version 4.001. Added option 48

“Reserved” for firmware version 5.002.

Default:

Min/Max:

0

0 / 65535

16-bit

Int

Options:

1212 [Acc Dec Filter]

Internal acceleration/deceleration calculation filter for the Torque Winder line

speed reference.

Default:

Min/Max:

Units:

30

0 / 5000

ms

16-bit

Int

1213 [Actual Comp]

Active compensation status (sums up the static, dynamic and inertial frictions) as a

percentage of the drive rated current.

Note: This parameter can be assigned to an analog output.

Default:

Min/Max:

Units:

Read Only

–/+200

%

16-bit

Int

1214 [Closed Loop En]

Enables/Disables closed loop tension control (used with a load cell).

Default:

Options:

0 =

0 =

1 =

“Disabled”

“Disabled”

“Enabled”

16-bit

Int

1215 [Speed Demand En]

Enables/Disables the speed reference calculation for the Torque Winder

application.

Default:

Options:

0 =

0 =

1 =

“Disabled”

“Disabled”

“Enabled”

16-bit

Int

1216 [Spd Match Torque]

Sets the torque current during the launching and change phase.

Default:

Min/Max:

Units:

100

0 / 200

%

16-bit

Int

1217 [W Reference]

Angular speed reference.

Note: This parameter can be assigned to an analog output; 10V = 100% of Par 45

[Max Ref Speed].

Default:

Min/Max:

Units:

Read Only

–/+8192

rpm

16-bit

Int

1160

1255 [Jog TW Speed]

Torque Winder jog reference. The parameter is entered as a percentage of Par 1160

[Line Speed Pct].

Default:

Min/Max:

Units:

0

0 / 100

%

16-bit

Int

1160

1256 [Jog TW Enable]

Enables/Disables the Torque Winder jog function.

Note: This parameter can be assigned to a digital input.

Default:

Options:

0 =

0 =

1 =

“Disabled”

“Disabled”

“Enabled”

16-bit

Int

Fil

e

Gr

oup

No

.

Parameter Name & Description

See

page 110

for symbol descriptions

Values

Da

ta

T

yp

e

Rela

ted

A

0 =

“Not Used”

17 = “Max Fld Pct” (Par 467)

34 = “UsrDefined15” (Par 518)

1 =

“Cur Lim Pos” (Par 8)

18 = “Reserved”

35 = “Load Comp” (Par 698)

2 =

“Cur Lim Neg” (Par 9)

19 = “UsrDefined0” (Par 503)

36 = “Out Volt Lvl” (Par 921)

3 =

“Reserved”

20 = “UsrDefined1” (Par 504)

37 = “Reserved”

4 =

“Reserved”

21 = “UsrDefined2” (Par 505)

38 = “Speed Ratio” (Par 1017)

5 =

“TrqRedCurLim” (Par 13)

22 = “UsrDefined3” (Par 506)

39 = “Reserved”

6 =

“Torque Ref” (Par 39)

23 = “UsrDefined4” (Par 507)

40 = “Reserved”

7 =

“Trim Torque” (Par 40)

24 = “UsrDefined5” (Par 508)

41 = “Tension Red” (Par 1179)

8 =

“Reserved”

25 = “UsrDefined6” (Par 509)

42 = “Reserved”

9 =

“Trim Ramp” (Par 42)

26 = “UsrDefined7” (Par 510)

43 = “Reserved”

10 = “Trim Speed” (Par 43)

27 = “UsrDefined8” (Par 511)

44 = “CloseLp Comp” (Par 1208)

11 = “Reserved”

28 = “UsrDefined9” (Par 512)

45 = “Reserved”

12 = “Reserved”

29 = “UsrDefined10” (Par 513)

46 = “Reserved”

13 = “Reserved”

30 = “UsrDefined11” (Par 514)

47 = “Reserved”

14 = “Adaptive Ref” (Par 183)

31 = “UsrDefined12” (Par 515)

48 = “Reserved”

15 = “Reserved”

32 = “UsrDefined13” (Par 516)

16 = “Reserved”

33 = “UsrDefined14” (Par 517)

A

A

A

A

A

A

A