Rockwell Automation 20P PowerFlex Digital DC Drive User Manual

Page 154

154

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

Chapter 3

Programming and Parameters

A

PPLIC

AT

IONS

PID

Con

tro

l

786

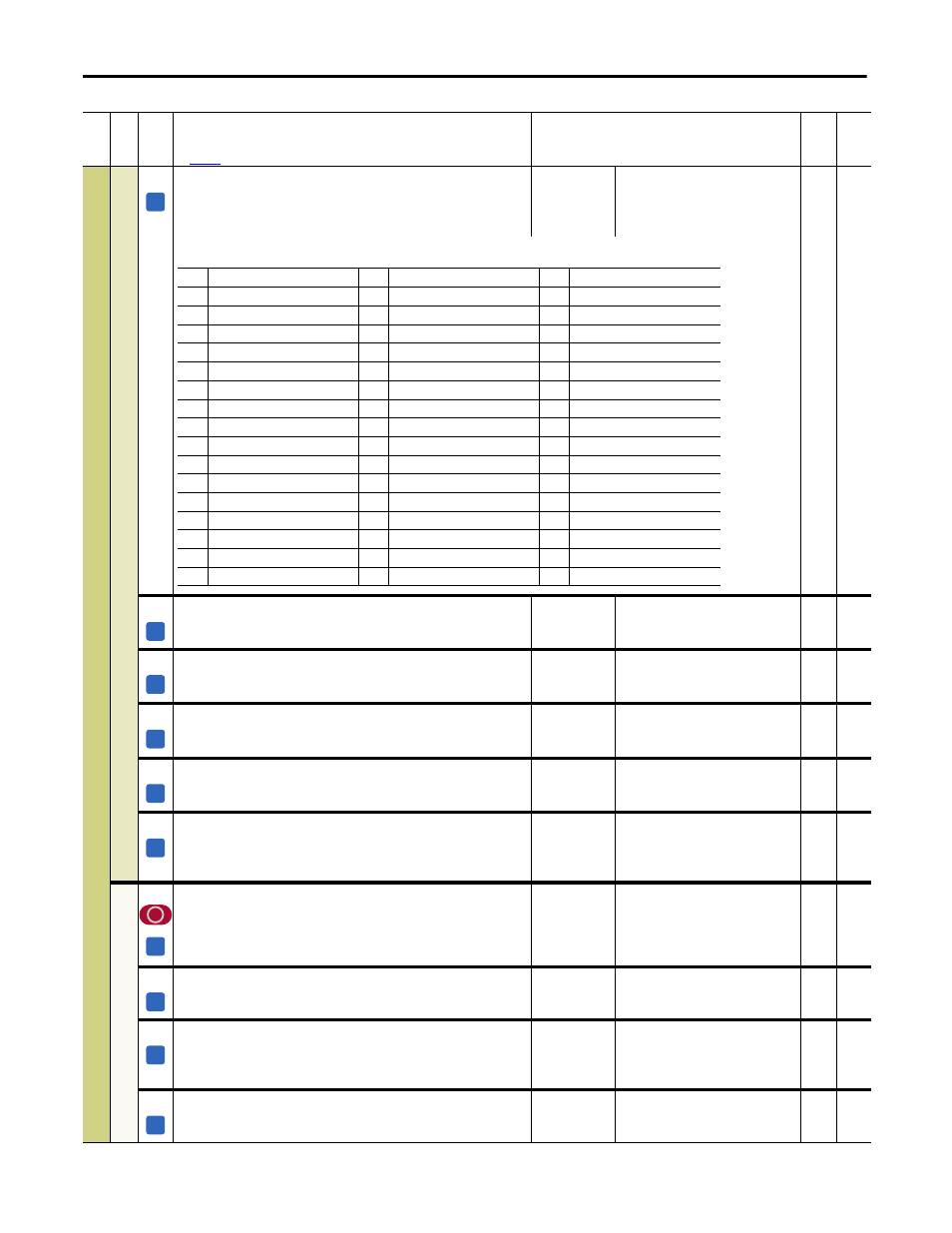

[PID Source]

Parameter number from which the PID source value will be read.

Notes: Added option 47 “Encoder Spd” for firmware version 4.001. Added option

48 “Resolver Spd” for firmware version 5.002.

Default:

0

“Not Used”

16-bit

Int

Options:

787

[PID Source Gain]

Gain of the input value to Par 786 [PID Source].

Default:

Min/Max:

1.00

–/+100.00

Real

786

1046 [PID Accel Time]

Ramp acceleration time after the block PID offset.

Default:

Min/Max:

Units:

0.00

0.00 / 900.00

s

Real

1047 [PID Decel Time]

Ramp deceleration time after the block PID offset.

Default:

Min/Max:

Units:

0.00

0.00 / 900.00

s

Real

1254 [PID Error Gain]

Gain percentage of Par 759 [PID Error].

Default:

Min/Max:

Units:

1.005

0.000 / 32.005

%

Real

759

1258 [Enable PI PD]

Indicates the combined status of Par 769 [Enable PI] and 770 [Enable PD]. If both

Par 769 and Par 770 are enabled then Par 1258 [Enable PI PD] displays "Enabled". If

either of Par 769 or Par 770 is disabled, Par 1258 [Enable PI PD] displays "Disabled".

Default:

Min/Max:

Read Only

Disabled / Enabled

16-bit

Int

769,

770

Init D

ia

m

C

alc

794

[Diameter Calc]

Enables/Disables the diameter calculation function. If this parameter has been

programmed via a digital input, it must be brought to a logical high level.

• “0” = The diameter calculation is disabled.

• “1” = The diameter calculation is enabled.

Default:

Min/Max:

0

0 / 1

16-bit

Int

795

[DncrPosSpd]

Desired motor speed when the dancer is positioned in its central working position.

Default:

Min/Max:

0

–/+100

16-bit

Int

796

[Max Deviation]

A value, expressed in counts of D/A, that corresponds to the position of maximum

shift admitted by the dancer. This value is considered the starting measurement of

the dancer movement during the initial diameter calculation phase.

Default:

Min/Max:

8000

0 / 10000

16-bit

Int

797

[Gear Box Ratio]

Ratio reduction between the motor and the roll (< = 1).

Default:

Min/Max:

1.000

0.001 / 1.000

Real

Fil

e

Gr

oup

No

.

Parameter Name & Description

See

page 110

for symbol descriptions

Values

Da

ta

T

yp

e

Rela

ted

A

0 =

“Not Used”

17 = “Max Fld Pct” (Par 467)

34 = “UsrDefined15” (Par 518)

1 =

“Cur Lim Pos” (Par 8)

18 = “Fld Ref Pct” (Par 500)

35 = “Load Comp” (Par 698)

2 =

“Cur Lim Neg” (Par 9)

19 = “UsrDefined0” (Par 503)

36 = “Out Volt Lvl” (Par 921)

3 =

“CurLimPosOut” (Par 10)

20 = “UsrDefined1” (Par 504)

37 = “Filt Trq Cur” (Par 928)

4 =

“CurLimNegOut” (Par 11)

21 = “UsrDefined2” (Par 505)

38 = “Speed Ratio” (Par 1017)

5 =

“TrqRedCurLim” (Par 13)

22 = “UsrDefined3” (Par 506)

39 = “Spd Draw Out” (Par 1018)

6 =

“Torque Ref” (Par 39)

23 = “UsrDefined4” (Par 507)

40 = “Roll Diam” (Par 1154)

7 =

“Trim Torque” (Par 40)

24 = “UsrDefined5” (Par 508)

41 = “Tension Red” (Par 1179)

8 =

“TorqueReg In” (Par 41)

25 = “UsrDefined6” (Par 509)

42 = “Torq Cur Pct” (Par 1193)

9 =

“Trim Ramp” (Par 42)

26 = “UsrDefined7” (Par 510)

43 = “Ten Ref Pct” (Par 1194)

10 = “Trim Speed” (Par 43)

27 = “UsrDefined8” (Par 511)

44 = “CloseLp Comp” (Par 1208)

11 = “Ramp In” (Par 110)

28 = “UsrDefined9” (Par 512)

45 = “Actual Comp” (Par 1213)

12 = “Ramp Out” (Par 113)

29 = “UsrDefined10” (Par 513)

46 = “W Reference” (Par 1217)

13 = “Speed Reg In” (Par 118)

30 = “UsrDefined11” (Par 514)

47 = “Encoder Spd” (Par 420)

14 = “Adaptive Ref” (Par 183)

31 = “UsrDefined12” (Par 515)

48 = “Resolver Spd” (Par 428)

15 = “Arm Cur Pct” (Par 199)

32 = “UsrDefined13” (Par 516)

16 = “SpdRegOutPct” (Par 236)

33 = “UsrDefined14” (Par 517)

A

A

A

A

A

A

A

A

A