Rockwell Automation 20P PowerFlex Digital DC Drive User Manual

Page 157

Rockwell Automation Publication 20P-UM001I-EN-P - February 2013

157

Programming and Parameters

Chapter 3

APPL

IC

AT

IONS

Diame

ter Cal

c

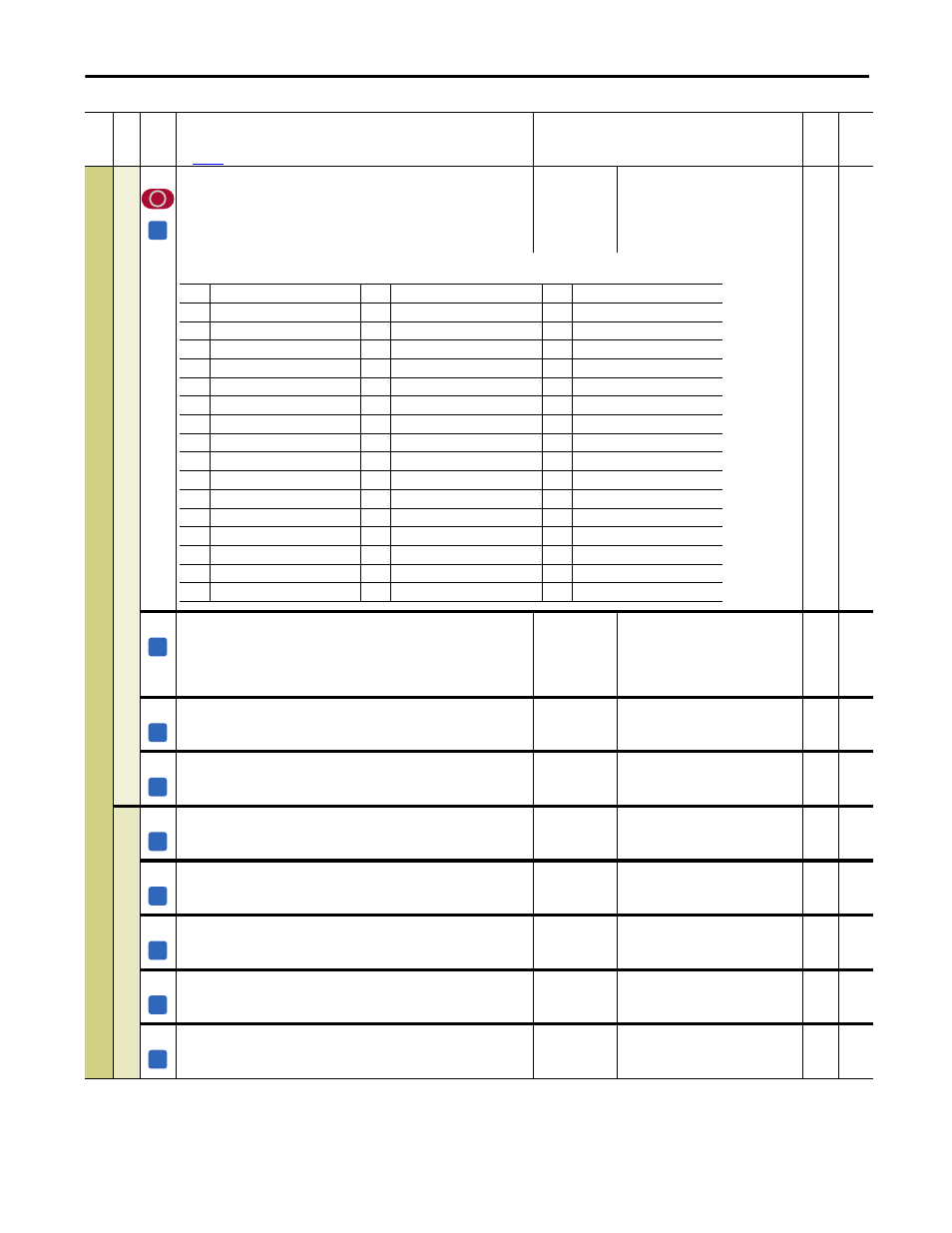

1204 [Line Spd Source]

Parameter number from which the line speed source for the winder function value

will be read.

Notes: Added options 0…47 for firmware version 4.001. Added option 48

“Resolver Spd” for firmware version 5.002.

Default:

0 =

“Not Used”

16-bit

Int

Options:

1205 [Diam Inc Dec En]

This parameter It is used to improve system stability for winder/unwinder

applications. If this parameter is enabled and if applied to a winder, the calculated

diameter can never decrease; if applied to an unwinder, the calculated diameter

can never increase.

Default:

Options:

1 =

0 =

1 =

“Enabled”

“Disabled”

“Enabled”

16-bit

Int

1206 [Diam Init Filter]

Initial filter on the diameter calculation.

Default:

Min/Max:

Units:

100

0 / 5000

ms

16-bit

Int

1207 [Diam Stdy Delay]

The amount of time during which the value of Par 1206 [Diam Init Filter] is kept

active after the value defined in Par 1155 [Line Spd Thresh] has been overcome.

Default:

Min/Max:

Units:

0

0 / 60000

ms

16-bit

Int

1155,

1206

W

inde

r F

u

n

cti

on

s

1171 [Variable J Comp]

Torque compensation due to the wound material as a percentage of the drive rated

current.

Default:

Min/Max:

Units:

0.00

0.00 / 199.99

%

Real

1172 [Constant J Comp]

Compensation of the fixed section (motor, reducer, pin) as a percentage of the drive

rated current.

Default:

Min/Max:

Units:

1.00

– / +100.00

%

Real

1173 [Materl Width Pct]

Width of the wound material as a percentage of the maximum width.

Default:

Min/Max:

Units:

100.00

0.00 / 100.00

%

Real

1174 [Static Friction]

Compensation for static friction as a percentage of the drive rated current.

Default:

Min/Max:

Units:

0.00

0.00 / 199.99

%

Real

1175 [Dynamic Friction]

Compensation for dynamic friction as a percentage of the drive rated current.

Default:

Min/Max:

Units:

0.00

0.00 / 199.99

%

Real

Fil

e

Gr

oup

No

.

Parameter Name & Description

See

page 110

for symbol descriptions

Values

Da

ta

T

yp

e

Rela

ted

A

0 =

“Not Used”

17 = “Max Fld Pct” (Par 467)

34 = “UsrDefined15” (Par 518)

1 =

“Cur Lim Pos” (Par 8)

18 = “Fld Ref Pct” (Par 500)

35 = “Load Comp” (Par 698)

2 =

“Cur Lim Neg” (Par 9)

19 = “UsrDefined0” (Par 503)

36 = “Out Volt Lvl” (Par 921)

3 =

“CurLimPosOut” (Par 10)

20 = “UsrDefined1” (Par 504)

37 = “Filt Trq Cur” (Par 928)

4 =

“CurLimNegOut” (Par 11)

21 = “UsrDefined2” (Par 505)

38 = “Speed Ratio” (Par 1017)

5 =

“TrqRedCurLim” (Par 13)

22 = “UsrDefined3” (Par 506)

39 = “Spd Draw Out” (Par 1018)

6 =

“Torque Ref” (Par 39)

23 = “UsrDefined4” (Par 507)

40 = “Roll Diam” (Par 1154)

7 =

“Trim Torque” (Par 40)

24 = “UsrDefined5” (Par 508)

41 = “Tension Red” (Par 1179)

8 =

“TorqueReg In” (Par 41)

25 = “UsrDefined6” (Par 509)

42 = “Torq Cur Pct” (Par 1193)

9 =

“Trim Ramp” (Par 42)

26 = “UsrDefined7” (Par 510)

43 = “Ten Ref Pct” (Par 1194)

10 = “Trim Speed” (Par 43)

27 = “UsrDefined8” (Par 511)

44 = “CloseLp Comp” (Par 1208)

11 = “Ramp In” (Par 110)

28 = “UsrDefined9” (Par 512)

45 = “Actual Comp” (Par 1213)

12 = “Ramp Out” (Par 113)

29 = “UsrDefined10” (Par 513)

46 = “W Reference” (Par 1217)

13 = “Speed Reg In” (Par 118)

30 = “UsrDefined11” (Par 514)

47 = “Encoder Spd” (Par 420)

14 = “Adaptive Ref” (Par 183)

31 = “UsrDefined12” (Par 515)

48 = “Resolver Spd” (Par 428)

15 = “Arm Cur Pct” (Par 199)

32 = “UsrDefined13” (Par 516)

16 = “SpdRegOutPct” (Par 236)

33 = “UsrDefined14” (Par 517)

A

A

A

A

A

A

A

A