Sensaphone SCADA 3000 Users manual User Manual

Page 267

25-5

Chapter 25: Relay Output Module

Notes on Correct Use

The Relay Output Module can be used to control a wide variety of AC and DC devices.

However, care must be taken to insure that the module is not used in such a way that will

severely degrade the life expectancy of the relays or cause the Relay Output Module to mal-

function (e.g. microprocessor reset). Do not continuously apply a voltage higher than the

rated maximum voltage to any relay. Do not switch loads that exceed the rated capacity of the

relay. Avoid switching high-current inductive loads as these will generate significant radiated

noise when switching, possibly causing the microprocessor to reset. Also, do not run your out-

put wiring together with your input wiring. This will almost always cause errors in your input

readings because of signal coupling. Be sure to follow National Electric Code guidelines for

proper wiring and safety when working with high voltage circuits. (See the Relay Output Module

Specifications for complete rating information.)

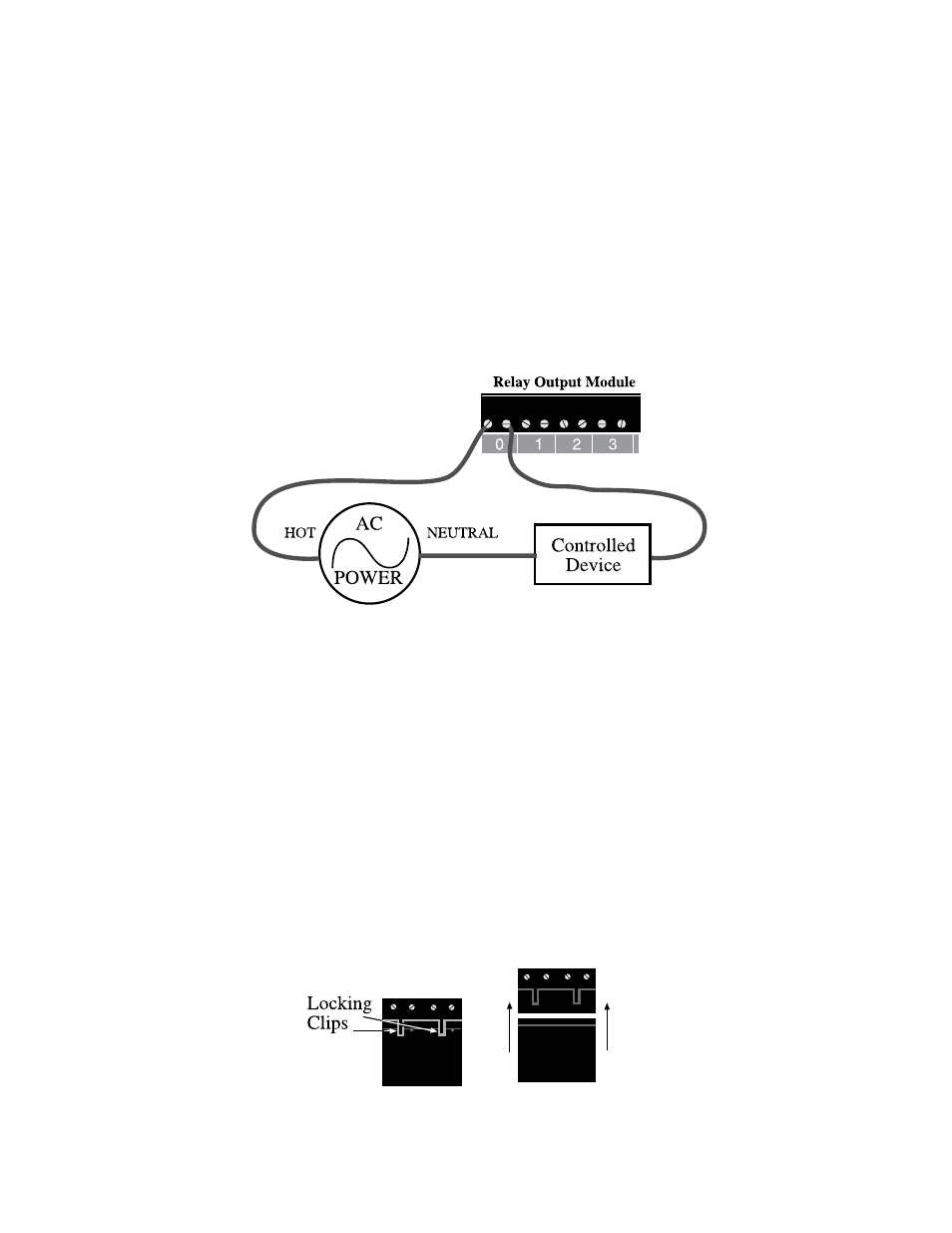

The following wiring diagram shows a typical switching application.

Figure 8: Relay Output Wiring

The output wiring terminals are designed to accept #14AWG to #24AWG stranded wires. Be

sure to use wire of the proper type and gauge for your application. The recommendations listed

below will minimize interference to other signals.

• Route the power supply and communications cables to the module by a sepa-

rate path from wiring to I/O devices. Where paths must cross, their intersection

should be perpendicular.

• Do not run signal or communications wiring and power in the same conduit.

• Segregate I/O wiring by signal type. Bundle wiring with similar electrical charac-

teristics together.

• Allow at least two inches between the module and I/O wiring ducts.

The three terminal blocks on the Relay Output Module are all removable for faster and more

convenient wiring of the I/O module. They should only be removed or attached when power

to the module is OFF. To remove the terminal blocks use your thumb or forefinger to push the

screw section of the terminal block straight out (see figure below).

Figure 9: Removing terminal blocks