Referencing scada 3000 i/o points, Sample application, Referencing scada 3000 i/o points -3 – Sensaphone SCADA 3000 Users manual User Manual

Page 235: Sample application: -3

22-3

Chapter 22: Distributed Control using Visual Basic

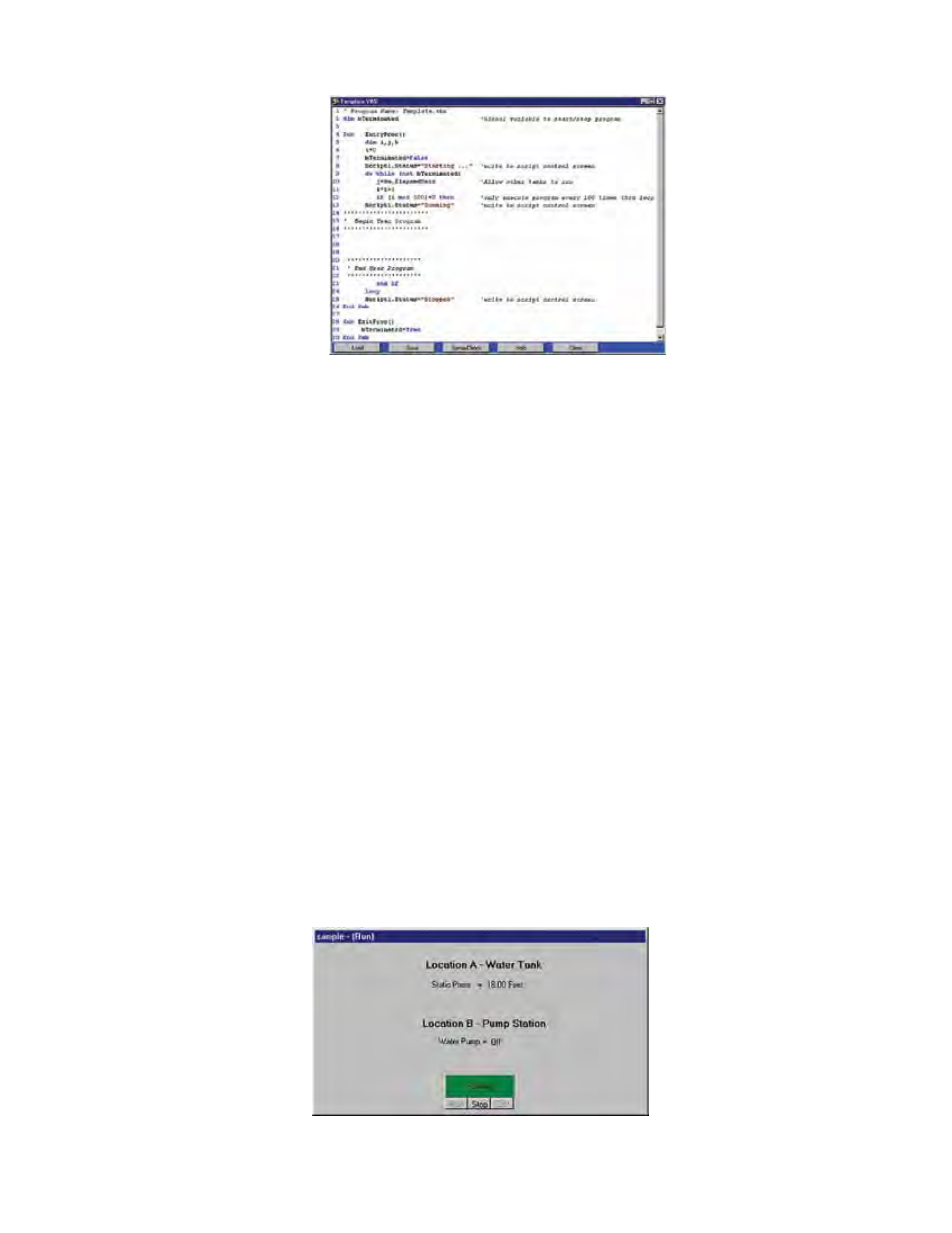

Figure 5: Template program

Referencing SCADA 3000 I/O Points

Every I/O point or component that is placed on the Real-time screen is assigned a unique tag-

name which is made up of the Component Name and the Property Name. The Component Name is

based on the type of component used on the screen along with a number. Each time that com-

ponent is used on the screen the number will increase. For example, a DataPointValue compo-

nent gets the name DataPointValue#. The # part of the name increases by one each time a new

point is added to the screen. The Component Name can be viewed on the property form when

the component is selected. I/O points are referenced in the script program using a combination

of the Component Name and the Component Property. The properties of a component are those

listed on the property form. The format for referencing I/O points or components in your

script program is ComponentName.ComponentProperty.

As an example, if you were going to reference the numerical value of an Input on your Real-

time screen you would use the DataPointValue component. The property you would read or

write would be the value property. So the complete tagname would be DataPointValue1.value.

You use the tagnames to read and write to I/O in your Distributed Control program.

Sample Application:

Suppose you have two SCADA 3000 units, one at Location A, the other at Location B. At

location A there is a water tank with a level transducer connected to the SCADA 3000. At

Location B there is a pump, which is connected to an output on the SCADA 3000. When the

pump is turned on at Location B, water will be pumped into the tank at Location A.

A host computer is set up so that it is continuously online with both SCADA 3000 units. A

Real-time screen is created, which displays the level in the tank and the On/Off status of the

pump. See below.

Figure 6: RT Screen