3 monitoring the safety function with a plc, Monitoring the safety function with a plc, Safety engineering – Lenze E82xVxxxKxxxxx User Manual

Page 500: Requirements the following conditions must be met, Of the drive (see parameterisation example)

Safety engineering

Functional test

Monitoring the safety function with a PLC

l

500

EDS82EV903 EN 3.0

14.4.3

Monitoring the safety function with a PLC

K

SR

µC

PWM

PWM

CINH

DIGOUT

DC 24 V

Z2

Z1

8200 vector

S1

S2

IN 1

IN 2

IN 3

IN 4

34

X3.1

33

K32

K31

28

Ax

&

8200vec111

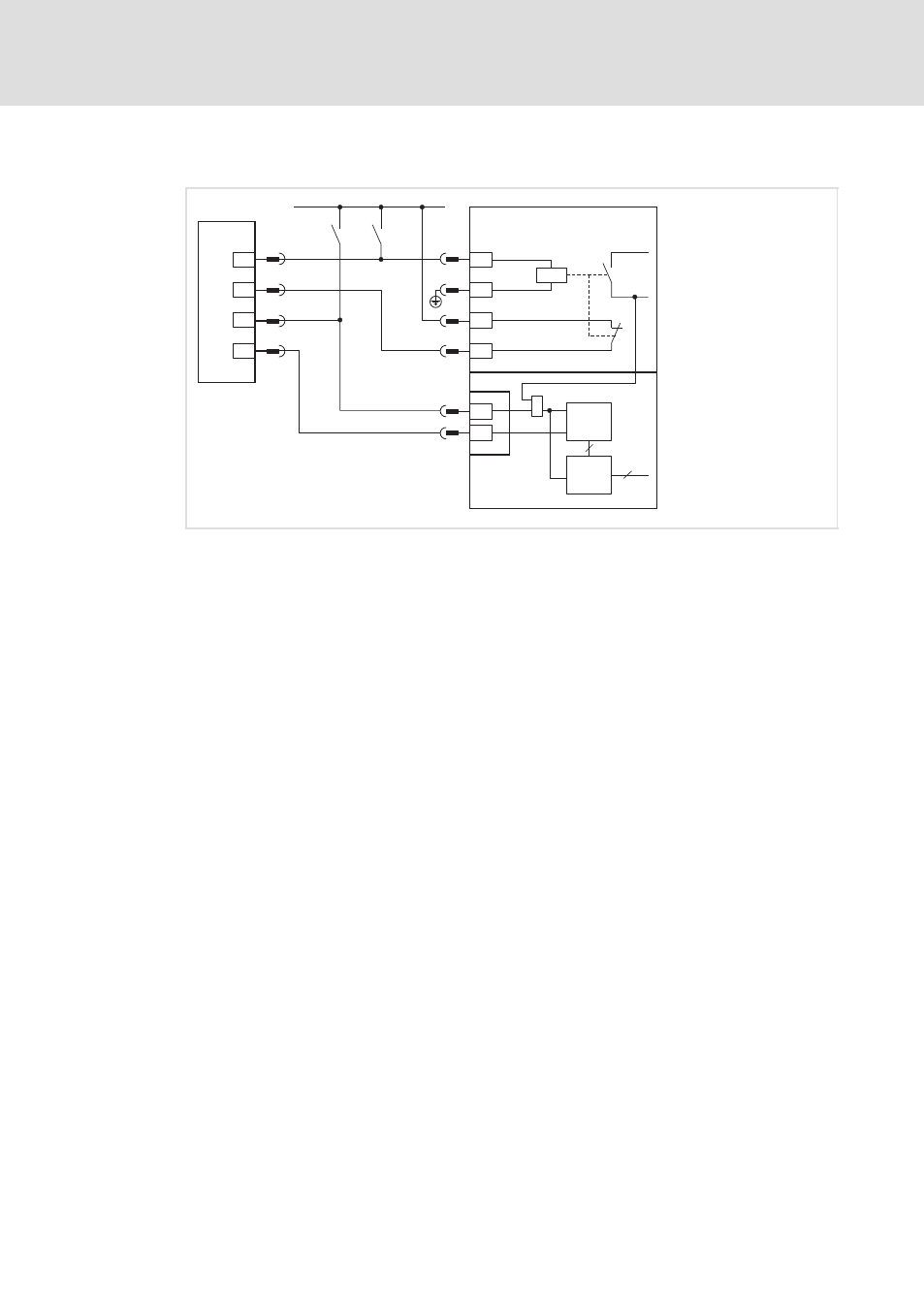

Fig. 14−4

Circuit diagram for monitoring the safety function with a PLC

S1, S2

Separate options for disconnecting the two disconnecting paths

K

SR

Safety relay

X3.1/34

Control of safety relay

X3.1/33

Control of safety relay (GND)

X3.1/K32 Positively driven feedback contact (24 V)

X3.2/K31 Positively driven feedback contact

Z1

Standard I/O or application I/O

Ax

Digital output for motor current evaluation

CINH

Controller inhibit

Z2

Programmable logic controller (PLC)

IN 1 − 4

Digital inputs

Requirements

The following conditions must be met:

ƒ

The PLC must be programmed such that the complete system is set to a safe state

immediately when the function check leads to an impermissible state.

ƒ

The parameter setting of a digital output must be such that you can conclude to the

output current I

motor

of the drive (see parameterisation example).