Function library – Lenze E82xVxxxKxxxxx User Manual

Page 269

Function library

Optimising the operating behaviour

Slip compensation

l

269

EDS82EV903 EN 3.0

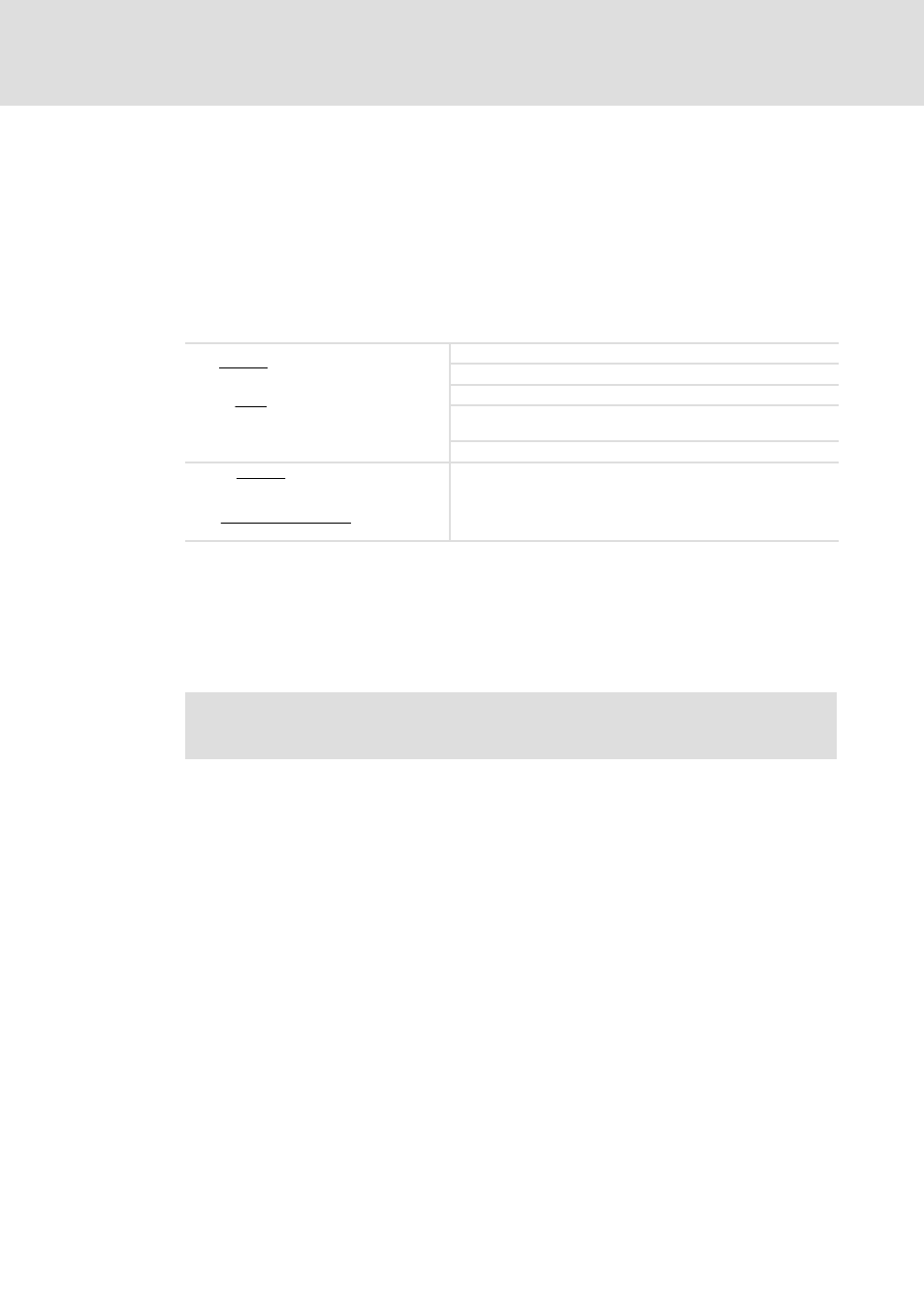

Manual adjustment

Manual adjustment of the slip compensation is only required if the motor parameter

identification is not carried out. For this purpose, a first coarse adjustment of the slip

compensation can be carried out on the basis of the motor data. Fine adjustment will be

carried out empirically when the drive is running:

Coarse adjustment

1. Roughly determine the slip compensation on the basis of the motor data and enter

it into C0021:

s +

n

rsyn

* n

r

n

rsyn

@ 100 %

n

rsyn

+ f

r

@ 60

p

s

Slip constant (C0021) [%]

n

rsyn

Synchronous motor speed [min

−1

]

n

r

Rated motor speed according to motor nameplate [min

−1

]

f

r

Rated motor frequency according to motor nameplate

[Hz]

p

Number of motor pole pairs (1, 2, 3, ...)

s + 1500 min

*1

*1435 min

*1

1500 min

*1

@ 100 % + 4.33 %

n

rsyn

+ 50Hz @ 60

2

+ 1500 min

*1

Example of a 4−pole motor / 1435 rpm / 50 Hz:

Preset C0021 = 4.3 %

Fine adjustment

2. Correct C0021 with the drive running until load−dependent speed drops do not occur

anymore in the desired speed range between idling and maximum motor load. The

following holds true as a guide value for correct slip compensation:

– Deviation from the rated speed

£ 0.5 % for output frequency 5 ... 50 Hz (87 Hz)

– Higher deviations are possible during field weakening operation

)

Note!

If C0021 is set too high, the drive may get unstable.

Setting tips

ƒ

With speed control, set C0021 = 0.0 with the internal process controller.

ƒ

A negative slip (C0021 < 0) in the "V/f characteristic control" operating mode results

in a "smoother" drive behaviour in case of high load impulses or applications

including multiple motors.