Commissioning, Important codes for quick commissioning – Lenze E82xVxxxKxxxxx User Manual

Page 220

Commissioning

Important codes for quick commissioning

l

220

EDS82EV903 EN 3.0

IMPORTANT

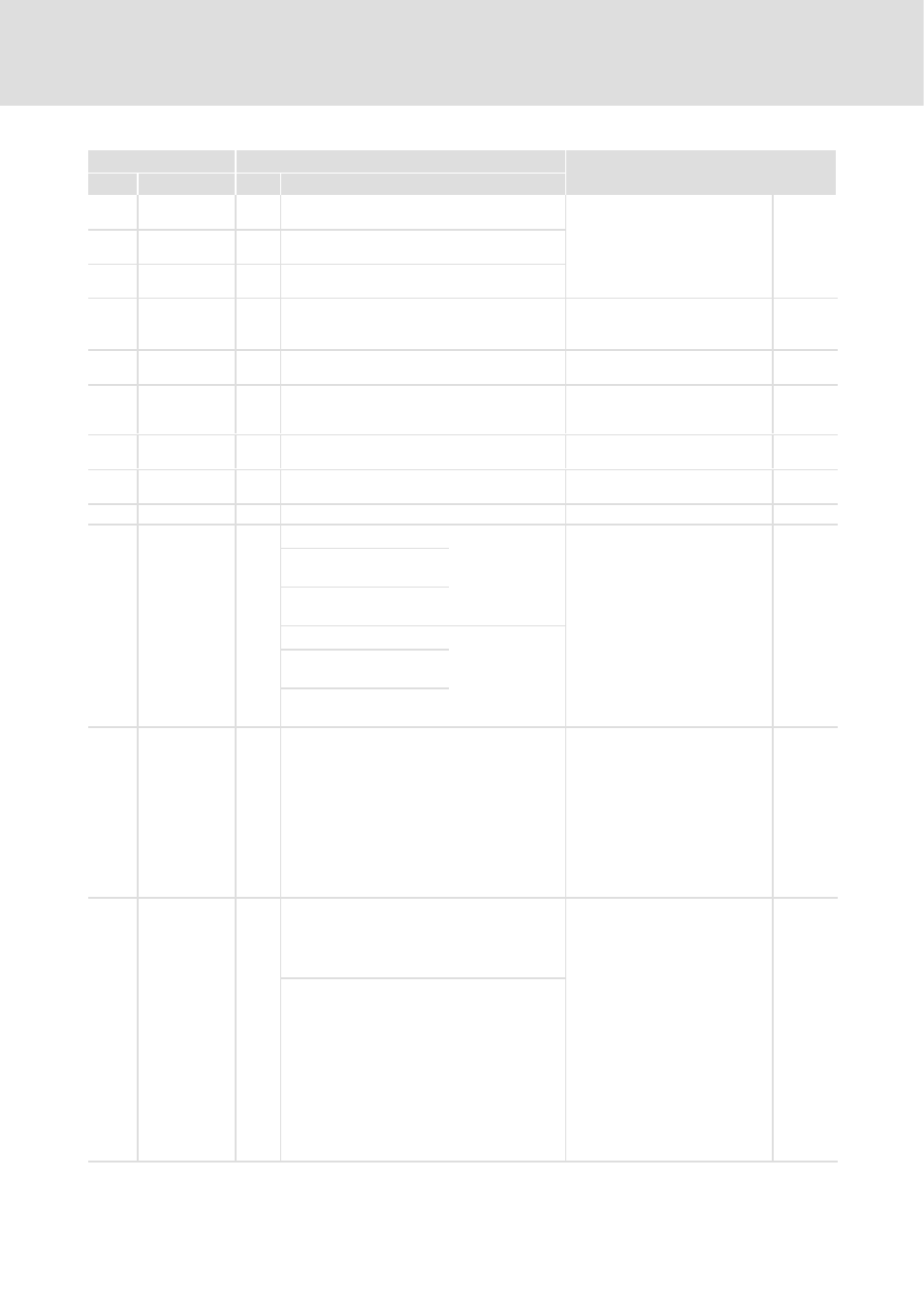

Possible settings

Code

Selection

Lenze

Name

No.

C0037 JOG1

20.00 −650.00

{0.02

Hz}

650.00 JOG = fixed setpoint

Additional fixed setpoints

ðC0440

^ 309

C0038 JOG2

30.00 −650.00

{0.02

Hz}

650.00

C0039 JOG3

40.00 −650.00

{0.02

Hz}

650.00

C0050

*

uSEr

Output freq.

(MCTRL1−

NOUT)

−650.00

{Hz}

650.00 Read only: Output frequency

without slip compensation

C0087 Rated motor

speed

à

300

{1 rpm}

16000

à

Device−dependent

^ 315

C0088 Rated motor

current

à

0.0

0.1 (A)

650.0

à

Device−dependent

0.0 ... 2.0 x rated output current of

the controller

^ 315

C0089 Rated motor

frequency

50

10

{1 Hz}

960

^ 315

C0090 Rated motor

voltage

à

50

{1 V}

500

à

230 V for 230 V controllers,

400 V for 400 V controllers

^ 315

C0091 Motor cos

ϕ

а

0.40

{0.1}

1.0

а

Device−dependent

^ 315

C0119

v

Configuration

of motor

temperature

monitoring

(PTC input) /

earth fault

detection

0

0

PTC input inactive

Earth fault

detection active

l

Configure signal output in

C0415

l

If several parameter sets are

used, monitoring has to be set

separately for every parameter

set.

l

Deactivate earth fault detection

if the earth fault detection is

actuated unintentionally.

l

If the earth fault detection is

activated, the motor starts with

a delay of approx. 40 ms after

controller enable has been set.

^ 359

1

PTC input active,

TRIP effected

2

PTC input active,

warning effected

3

PTC input inactive

Earth fault

detection inactive

4

PTC input active,

TRIP effected

5

PTC input active,

warning effected

C0140

*

Additive

frequency

setpoint

(NSET1−NADD)

0.00

−650.00

{0.02

Hz}

650.00

l

Selection via

j function of

the keypad or parameter

channel

l

Acts additively on the main

setpoint

l

Value will be stored when

switching the mains or

removing the keypad

l

C0140 is only transferred

during parameter set transfer

with GDC (not with keypad)

^ 311

C0148

*

s

Identifying

motor data

0

0

Ready

Only when the motor is cold!

1. Inhibit controller, wait until

drive is at standstill

2. Enter the correct values from

the motor nameplate in C0087,

C0088, C0089, C0090, C0091

3. Set C0148 = 1, confirm with

v

4. Enable controller:

The identification

– starts,

c goes out

– the motor "whistles" faintly

but it does not rotate!

– takes approx. 30 s

– is completed when

c is lit

again

5. Inhibit controller

^ 315

1

Start identification

l

V/f rated frequency (C0015), slip

compensation (C0021) and motor

stator inductance (C0092) are

calculated and saved

l

The motor stator resistance (C0084)

= total resistance of the motor cable

and motor is measured and saved