Rtd-based protection, Rtd monitoring – Rockwell Automation 825-P Modular Protection System for Motors User Manual User Manual

Page 83

Rockwell Automation Publication 825-UM004D-EN-P - November 2012

83

Configuring Protection & Logic Functions Chapter 6

You can connect up to six PTC thermistor sensors to the 825-P. The detectors are

typically embedded in the stator winding of the motor and they monitor the

actual temperature of the winding. This function is independent of the thermal

model and accounts for conditions such as ambient temperature, obstructed

cooling, etc. The sensors and their leads are also monitored for short-circuit

faults.

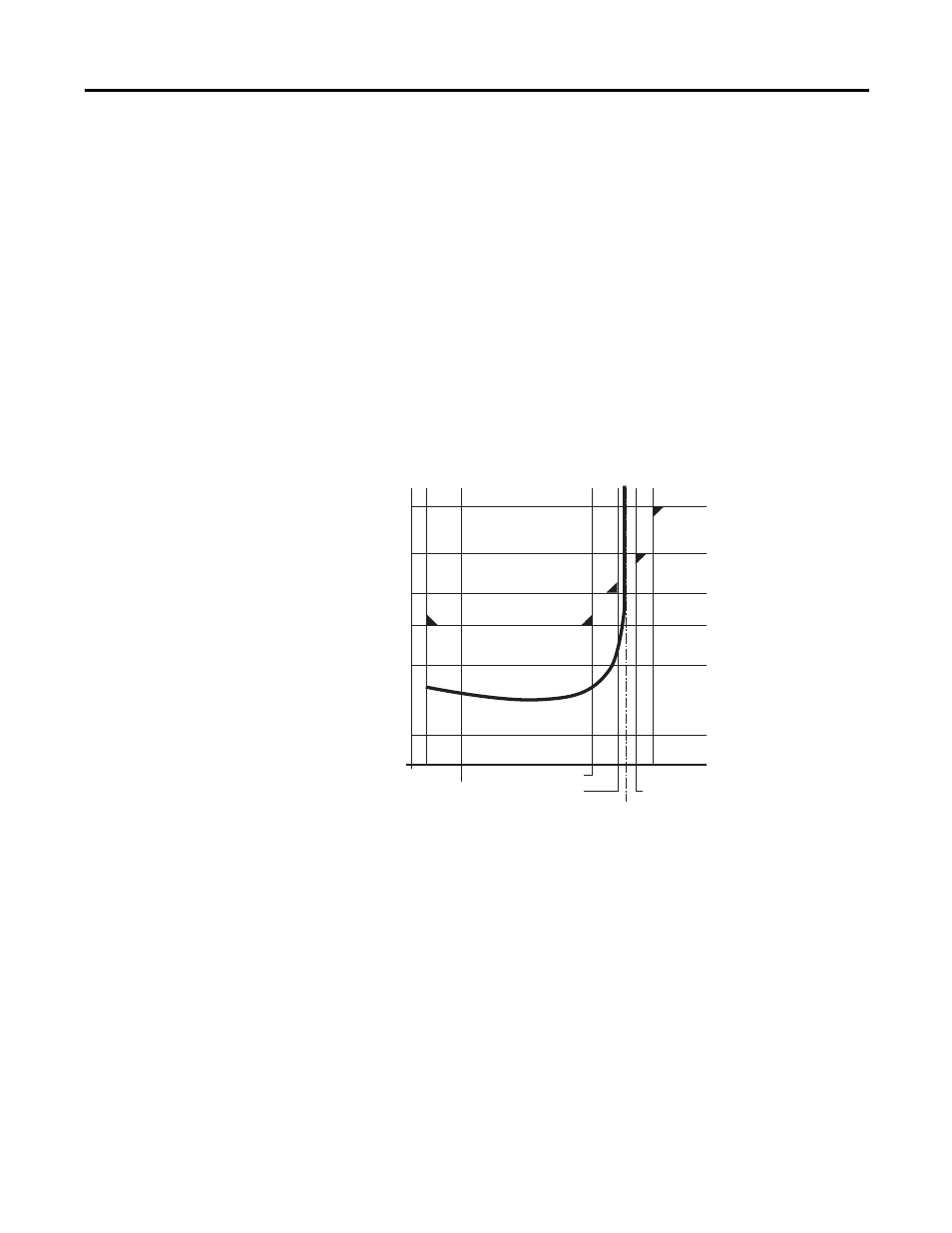

Figure 32 shows characteristics of the PTC. Setting PTC RESET MODE

determines reset mode for the PTC element. If set to Auto mode, the PTC trip

resets automatically when the element resets, if other trip conditions are not

present. If set to Man, operator intervention (e.g., front-panel push button) is

required to reset the PTC trip.

Figure 32 - Characteristic of PTC Sensors as per IEC 34-11-2

RTD-Based Protection

RTD Monitoring

When you connect the 825-PR12D RTD Module, the 825-P offers several

protection and monitoring functions whose settings are described in Table 27.

See Figure 4 for the location of the RTD module fiber-optic cable connector.

NOTE:

In addition to enabling the PTC function, you must also connect at least one (but no more

than six) thermistor(s) to the relay (see Figure XX for a connection diagram).

4000

1330

550

250

100

20

10

—20 °C

0 °C

TNF

TNF

R (W)

Nominal pickup temperature

Resistance to sensors

TNF — 20 K

TNF — 5 K

TNF + 15 K

TNF + 5 K

R (W)

NOTE:

The 825-P can monitor up to 12 RTDs connected to the 825-PR12D Module. Table 27 shows

Location, Type, and Trip/Warn Level settings only for RTD1; settings for RTD2 through RTD12

are similar.