Table 12 - motor codes, 4 and up – Rockwell Automation 825-P Modular Protection System for Motors User Manual User Manual

Page 72

72

Rockwell Automation Publication 825-UM004D-EN-P - November 2012

Chapter 6 Configuring Protection & Logic Functions

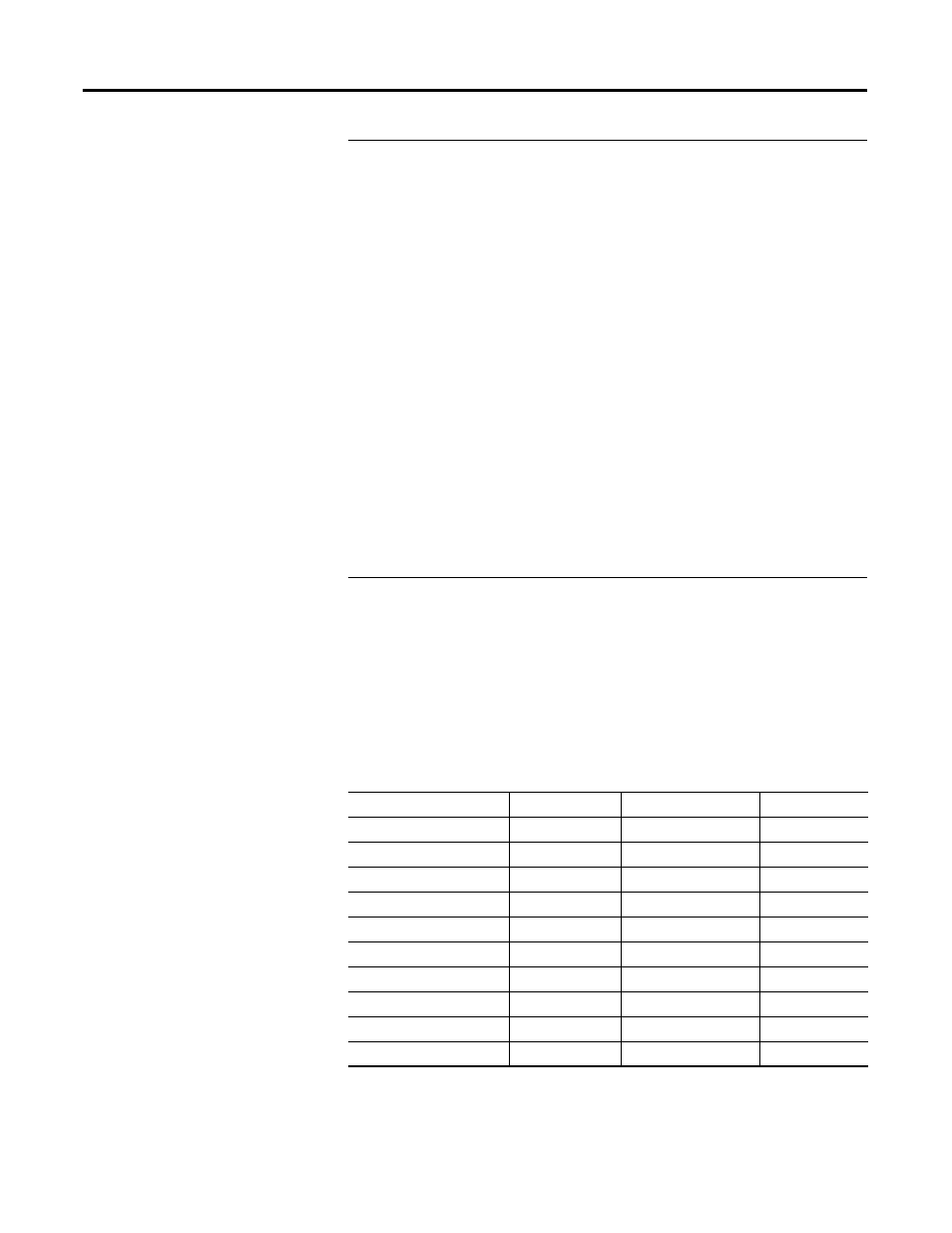

If the Locked Rotor Ampere rating for the motor is unknown, but the motor

has a Motor Code designation, use the following table as provided by NEMA

(National Electrical Manufacturer Association) to determine the locked rotor

ampere value.

➊

Locked kVA per horsepower range includes the lower figure up to, but not including, the higher figure; e.g., 3.14 is designated by letter

A and 3.15 is designated by letter B.

EXAMPLE

Thermal Element Setting

A 4000V 600 Hp motor is protected using the 825-P Thermal Overload Element. Motor

data sheet includes the following:

•

Rated Horsepower = 600 Hp

•

Rated Voltage = 4000V

•

Rated Full Load Current = 80 A

•

Rated Locked Rotor Amps = 480 A

•

Safe Stall Time at 100% Volts:

•

Cold = 18 seconds

•

Hot = 15 seconds

•

Service Factor = 1.2

Phase current transformers with 100:5 A rating and the MCM20 module are selected

for application. 825-P settings for application are calculated as shown below:

•

Current Transformer Ratio: := 100/5 := 20

•

Full Load Amps (Ie): := 80 A primary

•

Service Factor: := 1.2

•

Locked Rotor Amps: := 480.0/80.0 := 6.0 x Ie

•

Hot Locked Rotor Time: := 15.0 seconds

•

Run state time constant: := Auto

NOTE:

To prevent nuisance tripping from occurring when a motor operates at the rated service

factor, set Service Factor to 0.01 plus the motor nameplate value.

Table 12 - Motor Codes

Letter Designation

kVA/HP

➊

Letter Designation

kVA/HP

➊

A

0…3.15

L

9.0…10.0

B

3.15…3.55

M

10.0…11.2

C

3.55…4.0

N

11.2…12.5

D

4.0…4.5

P

12.5…14.0

E

4.5…5.0

R

14.0…16.0

F

5.0…5.6

S

16.0…18.0

G

5.6…6.3

T

18.0…20.0

H

6.3…7.1

U

20.0…22.4

J

7.1…8.0

V

22.4 and up

K

8.0…9.0