Troubleshooting, Commissioning – Lenze EVS9332xP User Manual

Page 226

Commissioning

Automatic control parameter identification

Troubleshooting

6.15

6.15.4

l

6.15−4

EDSVS9332P EN 5.0−07/2013

6.15.4

Troubleshooting

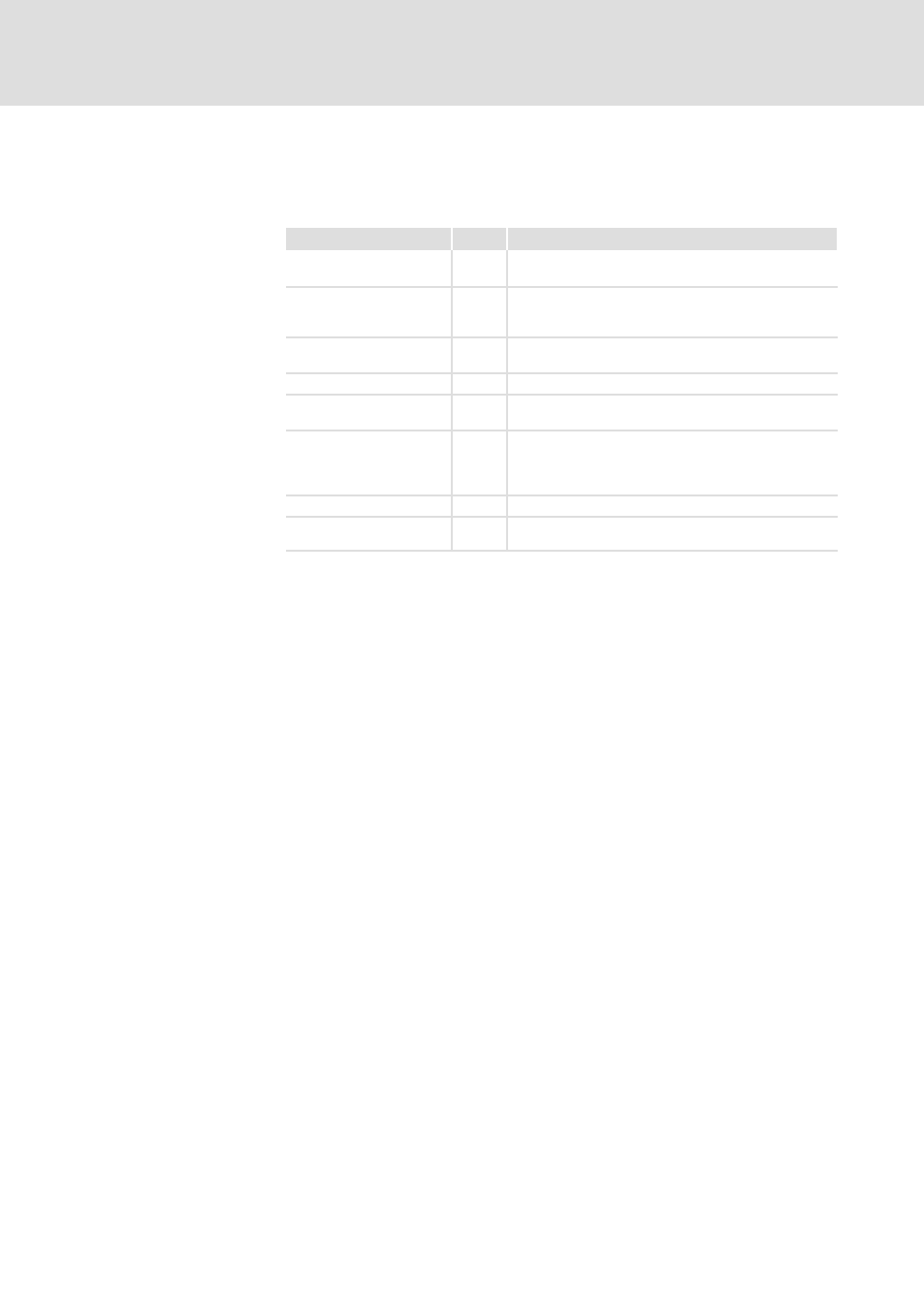

If an error occurs during the control parameter identification, you can

determine the error cause via the "Status" field or via C1181.

Error

C1181

Remedy

Control parameter

calculation not possible.

2

Check whether plant parameters are set reasonably

(C1187/C1188).

Too few scanning points

registered.

3

Change basic motion conditions (C1182

C1185), i.e.

increase torque, increase number of revolutions,

increase speed, reduce torque rise time.

Reference torque too low

4

l

Increase I

max

(C0022)

l

Check max. torque (C0057)

Speed at start

¹ 0

5

Stop drive and reactivate function

Controller inhibit set

during motion sequence

6

Repeat control parameter identification.

Minimum braking torque

not reached

Torque ramp too flat, or

max. torque too low.

7

Change basic motion conditions (C1182

C1185), i.e.

increase torque, increase number of revolutions,

increase speed, reduce torque rise time.

Time overflow

8

Select higher torque or shorter torque rise time.

Blocking of the drive

9

Release brake, check motor cable, eliminate mechanical

blocking of the drive.