INFICON IC/5 Thin Film Deposition Controller User Manual

Page 280

13 - 16

IP

N 07

4-

23

7A

E

IC/5 Operating Manual

NOTE: A more detailed troubleshooting guide is shipped with the sensor. Refer to

that manual for more detailed information in some cases

.

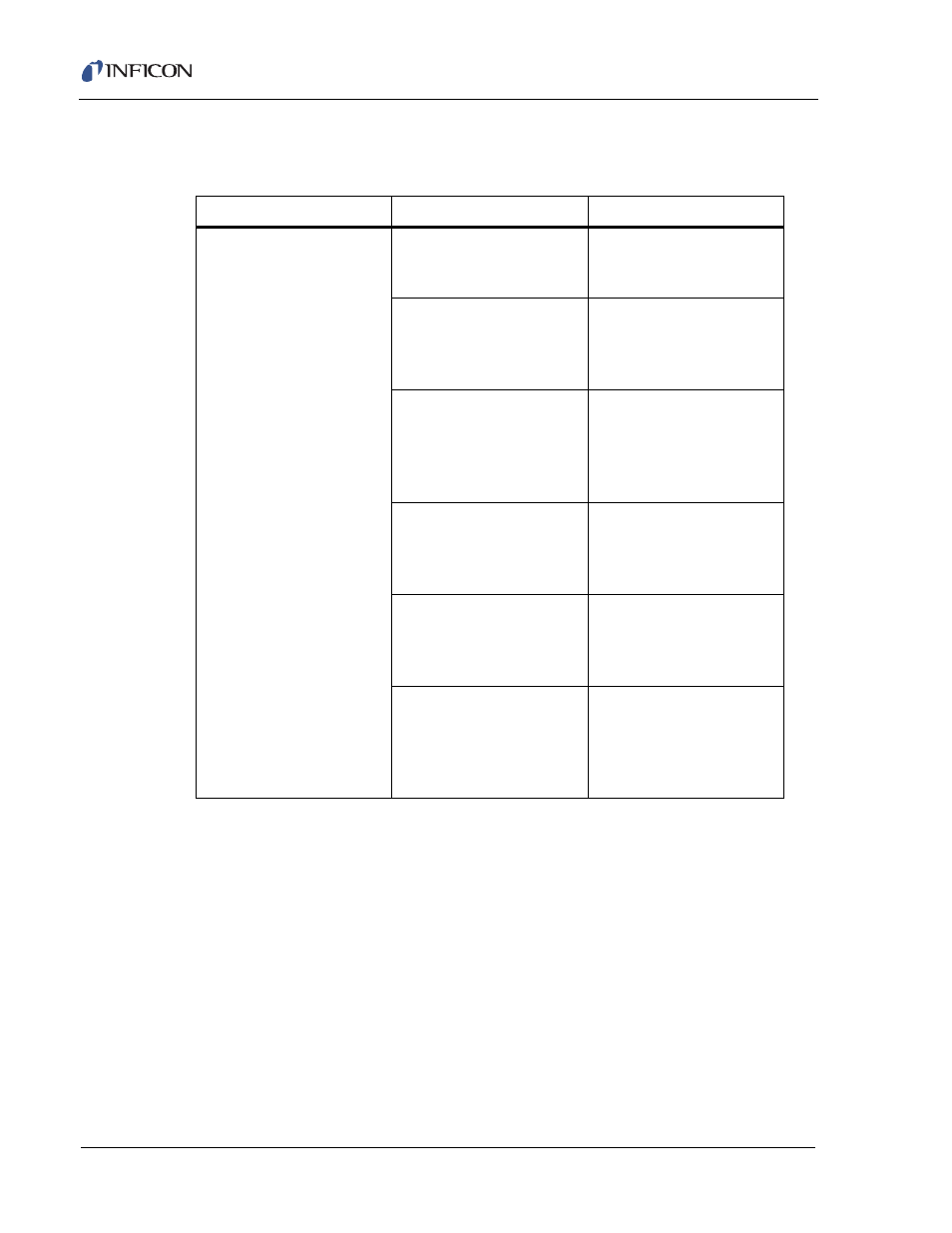

Table 13-2 Troubleshooting Transducers/Sensors

SYMPTOM

CAUSE

REMEDY

1. large jumps of thickness

reading during deposition

a. mode hopping due to

defective crystal

a. replace crystal, use

ModeLock™ measurement

system

b. stress causes film to peel

from crystal surface

b. replace crystal or use

high performance

RunSaver™ crystal; consult

factory

c. particulate or "spatter"

from molten source striking

crystal

c. thermally condition the

source thoroughly before

deposition, use a shutter to

protect the crystal during

source conditioning

d. scratches or foreign

particles on the crystal

holder seating surface

(improper crystal seating)

d. clean and polish the

crystal seating surface on

the crystal holder

e. small pieces of material

fell on crystal (for crystal

facing up sputtering

situation)

e. check the crystal surface

and blow it off with clean air

f. small pieces of magnetic

material being attracted by

the sensor magnet and

contacting the crystal

(sputtering sensor head)

f. check the sensor cover's

aperture and remove any

foreign material that may be

restricting full crystal

coverage