Front upstop wear pad replacement, Rear roller gap check, Section 11.3.10, “rear – Lull 944E-42 Service Manual User Manual

Page 818: Roller gap check

Transfer Carriage

11.16

Model 644E-42/944E-42

Rev. 6/04

11.3.9

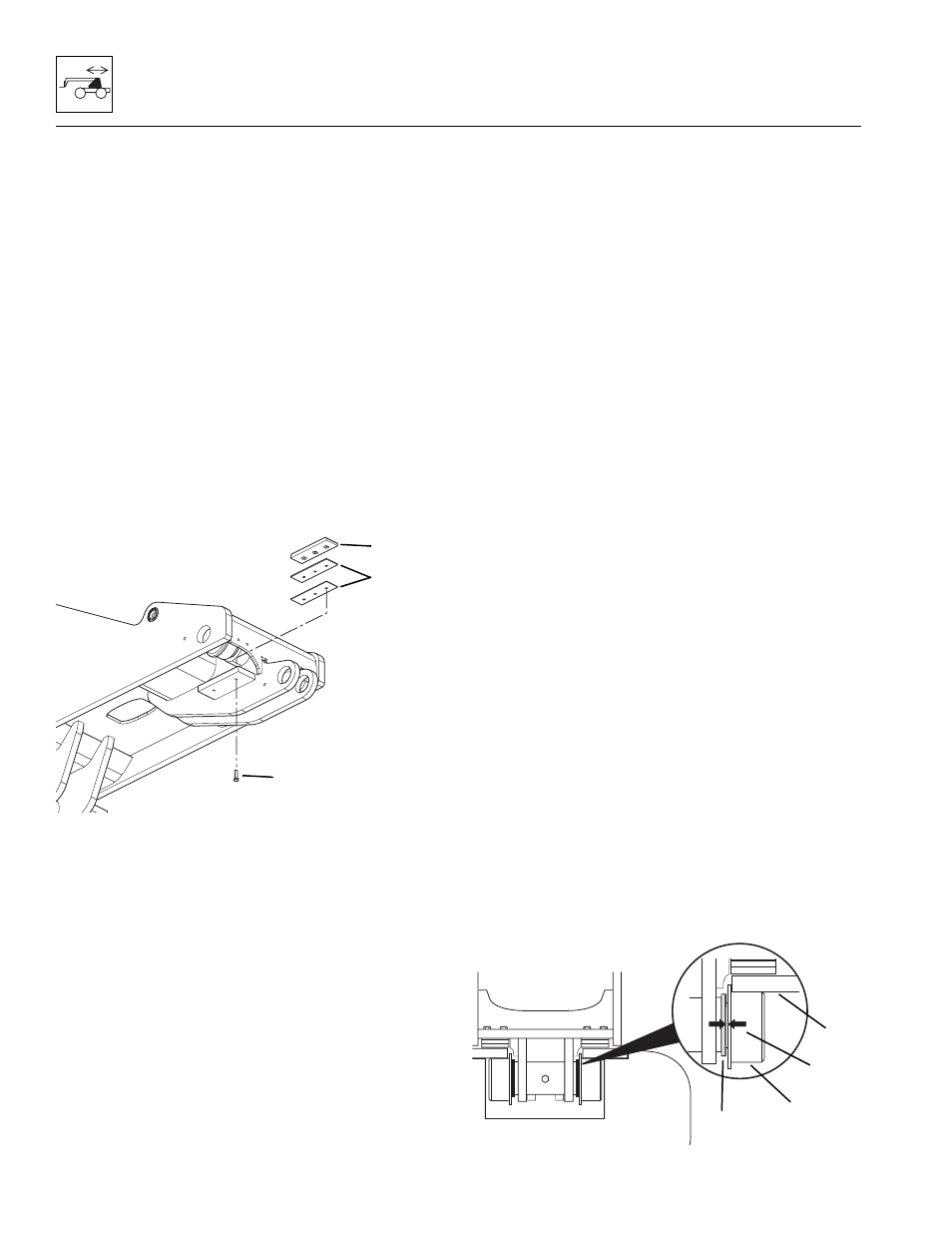

Front Upstop Wear Pad Replacement

Note: The attachment should remain attached to the

quick attach for this procedure.

1. Park the vehicle on level ground. Place the travel

select lever in the (N) NEUTRAL DETENT position,

engage the parking brake switch and raise the boom

to a horizontal (level) position.

2. Leave the transfer carriage completely retracted.

3. Fully extend the boom. The attachment must remain

slightly off the ground. Turn the vehicle OFF.

4. Remove the two capscrews (1) holding each wear

pad (3) to the plate under the rail at the front of the

transfer carriage.

5. Coat the capscrews (1) with Loctite

®

242 (blue). Place

the new wear pads with original shims (2) in place

and secure with the two capscrews (1). Torque the

capscrews to, 21 - 38 lb-ft (29 - 52 Nm).

11.3.10

Rear Roller Gap Check

Note: The attachment should remain attached to the

quick attach for these checks.

1. Park the vehicle on level ground. Place the travel

select lever in the (N) NEUTRAL DETENT position,

engage the parking brake switch and raise the boom

to a horizontal (level) position.

2. Fully retract the boom and fully retract the transfer

carriage. Shut the vehicle OFF.

3. This procedure will require the gap check to be

made in three separate locations. Transfer carriage

all the way retracted, transfer carriage all the way

forward and the transfer carriage moved forward

about halfway.

4. With the transfer carriage all the way retracted, use a

rawhide hammer to tap the rollers (4) against the

rails (5). Check the gap (6) between the roller and

the existing shims (7) with a feeler gauge. Check

both rear rollers and record the gap on each side.

5. Start the engine and move the transfer carriage all

the way forward. Shut the vehicle OFF. Use a

rawhide hammer to tap the rollers against the rails

and again check the gap (6) between the roller and

the existing shims of each roller with the transfer

carriage in this position. Record the gap of each

roller.

6. Start the engine and move the transfer carriage

about halfway back. Shut the vehicle OFF. Use a

rawhide hammer to tap the rollers against the rails

and once again check the gap (6) between the roller

and the existing shims of each roller with the transfer

carriage in this position. Record the gap of each

roller.

7. Find the location that had the smallest gap. This is

the position that the roller gap will be adjusted to, if

necessary. The maximum total gap of both sides

should not exceed 0.08" (2 mm).

8. If the total gap is larger than 0.08" (2 mm), the rollers

need to be shimmed.

MU1800

1

2

3

OU0970

4

5

6

7