Section 8.14.6, “extend/retract cylinder, Section 8.14.6, “extend/retract cylinder.”), Extend/retract cylinder – Lull 944E-42 Service Manual User Manual

Page 473: Warning

8.221

Model 644E-42/944E-42

Rev. 6/04

Hydraulic System

4. Use new oiled o-rings and reattach and secure the

hydraulic hoses to the slave cylinder fittings.

5. Start and run the engine at approximately one-third

to one-half throttle for about one minute without

moving the vehicle or operating any hydraulic

functions.

6. Inspect for leaks and check the level of the hydraulic

fluid in the reservoir. Shut the engine OFF. Add

hydraulic fluid if required.

7. Conduct a pressure check of the attachment tilt/

slave cylinder hydraulic circuit and bleed the circuit

as outlined in the procedure that follows.

8. Wipe up any hydraulic fluid spillage in, on, near and

around the vehicle, work area and tools.

g. Slave Cylinder Pressure Checking and Circuit

Bleeding

1. Attach a 5000 psi (345 bar) gauge to the main

control valve to test the attachment tilt and slave

cylinder hydraulic system circuit pressure. The unit is

equipped with test fittings from the factory. Refer to

Section 8.7, “Hydraulic System Testing.”

2. With no accessory installed on the quick attach, start

with the lift/lower and attachment tilt cylinders fully

retracted.

3. Fully extend the attachment tilt cylinder. Monitor

pressure while fully raising the lift/lower cylinder.

4. Fully retract the attachment tilt cylinder. Monitor

pressure while fully retracting the lift/lower cylinder.

5. Repeat Steps 3 thru 4 five times.

8.14.6

Extend/Retract Cylinder

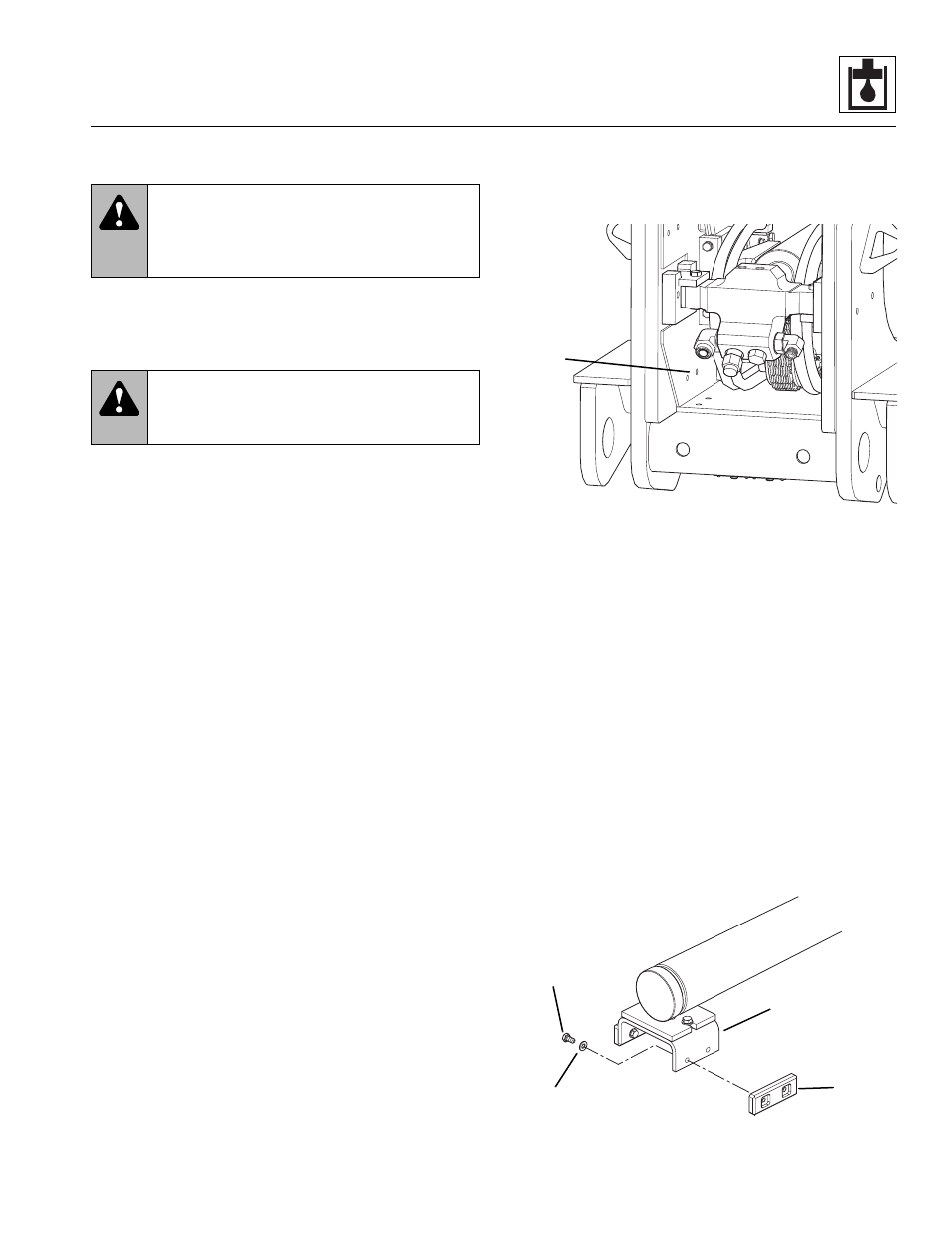

The extend/retract cylinder (22) is located within the inner

boom.

a. Extend/Retract Cylinder Removal

Procedures for removing the extend/retract cylinder

appear in Section 3.3.1, “Inner Boom Replacement.”

b. Extend Cylinder Wear Pad Inspection and

Replacement

After cylinder is removed, inspect the two wear pads (23)

mounted to the end of the cylinder. If the pads are worn

down to the wear pad indicator (angled cut) the pads

must be replaced.

Install the new pads onto the mount plate (24), and

secure in place with the capscrews (25) and washers

(26). Apply Loctite 242® (blue) to the threads of the

capscrews and install the capscrews. Torque the

capscrews to 31 lb-ft (42 Nm).

WARNING:

Avoid prolonged engine

operation in closed areas with inadequate

ventilation. Failure to properly ventilate exhaust

fumes can result in death or serious injury.

WARNING:

Escaping hydraulic fluid

under pressure can penetrate the skin, causing

death or serious injury.

MU0230

22

MU4480

23

24

25

26