Hydraulic cylinders, 14 hydraulic cylinders, General cylinder disassembly instructions – Lull 944E-42 Service Manual User Manual

Page 464: General cylinder cleaning instructions, General cylinder assembly instructions, Warning

Hydraulic System

8.212

Model 644E-42/944E-42

Rev. 6/04

8.14

HYDRAULIC CYLINDERS

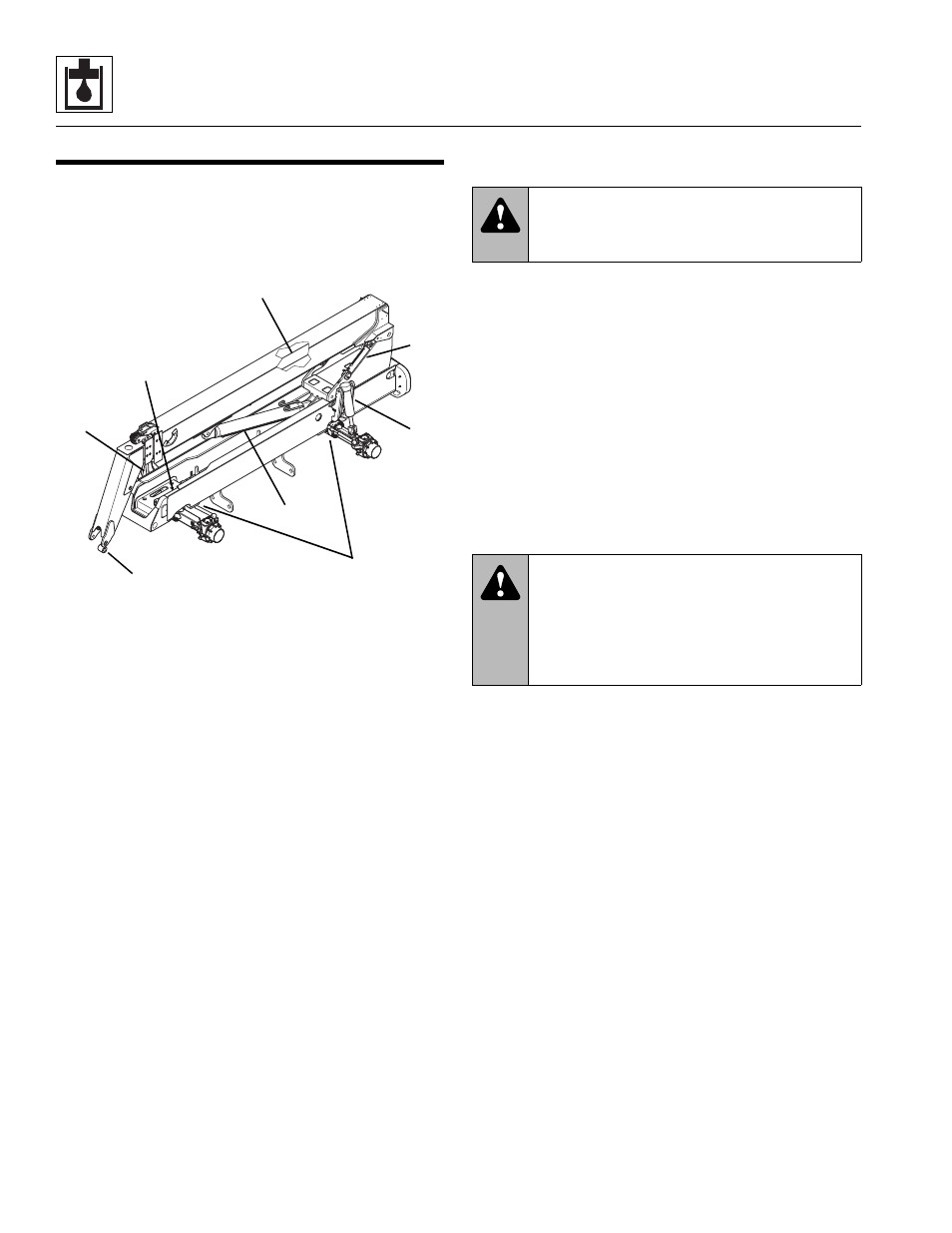

This section covers servicing the attachment tilt (1),

slave (2), extend/retract (3), lift/lower (4), frame sway (5),

stabilizer (6), steering (7) and transfer carriage (8)

cylinders on the vehicle.

There are many factors involved with the proper

disassembly, cleaning, inspection, repair and reassembly

of hydraulic cylinders; therefore, only qualified

professionals with proper training, supervision, tools and

equipment should rebuild the cylinders used on this

vehicle.

For example, special pin spanner wrenches of the correct

size are needed to disassemble the cylinders. Also, the

lift/lower cylinder rod locknut must be torqued to

2200-2600 lb-ft (2983-3525 Nm); this requires a special

torque wrench and/or torque multiplier. If the proper

knowledge and equipment are not available, the cylinders

must be sent out for rebuilding by a competent

professional at a company that specializes in rebuilding

agricultural and commercial heavy-equipment hydraulic

cylinders.

Rebuild cylinders only in a clean, well-lighted area where

all components can be carefully and thoroughly

inspected. If leaving a cylinder dismantled for any length

of time longer than the immediate rebuilding period, and

especially in high-humidity environments, coat the metal

parts with a suitable preservative and place them in

protective storage.

Refer to the specific instructions for removal, rebuilding

and installation of each cylinder.

8.14.1

General Cylinder Disassembly

Instructions

IMPORTANT: Avoid the use of excessive heat, which

will damage parts and make them unusable.

Some cylinder parts are sealed with a special organic

sealant and locking compound. Before attempting to

disassemble these parts, remove any accessible seals

from the area of the bonded parts. Wipe off any hydraulic

oil, then heat the part(s) uniformly to break the bond. A

temperature of 300-400° F (149-204° C) will destroy the

bond. Avoid overheating, or the parts may become

distorted or damaged. Apply sufficient torque for removal

while the parts are still hot. The sealant often leaves a

white, powdery residue on threads and other parts, which

must be removed by brushing with a soft brass wire brush

prior to reassembly.

DO NOT attempt to salvage cylinder seals, sealing rings

or o-rings. ALWAYS use a new, complete seal kit when

rebuilding hydraulic components. Consult the parts

catalog for ordering information.

Note: An additional o-ring may be included at the base

of the cylinder rod. This additional o-ring may be

discarded, as it served only in a temporarily protective

role.

8.14.2

General Cylinder Cleaning Instructions

Clean all reusable metal parts thoroughly after

disassembly and prior to inspection. Use an approved

solvent such as trichlorethylene.

8.14.3

General Cylinder Assembly Instructions

1. Before reassembly, ensure that parts are clean and

free from foreign matter. Use an approved solvent for

cleaning, such as trichlorethylene.

2. Use the proper tools for specific installation tasks.

Clean tools are required for installation.

3. Protect the finish on the rod at all times. Damage to

the rod can cause premature seal failure.

MU3680

1

2

3

4

5

6

7

8

WARNING:

To help prevent severe

burns, proceed with caution when applying

heat to parts.

WARNING:

Significant pressure may be

trapped inside the cylinder. Exercise caution when

removing a counterbalance valve or a

pilot-operated check valve from a cylinder.

Escaping hydraulic fluid under pressure can

penetrate the skin, causing death or serious injury.