Warning – Lull 944E-42 Service Manual User Manual

Page 436

Hydraulic System

8.184

Model 644E-42/944E-42

Rev. 6/04

f.

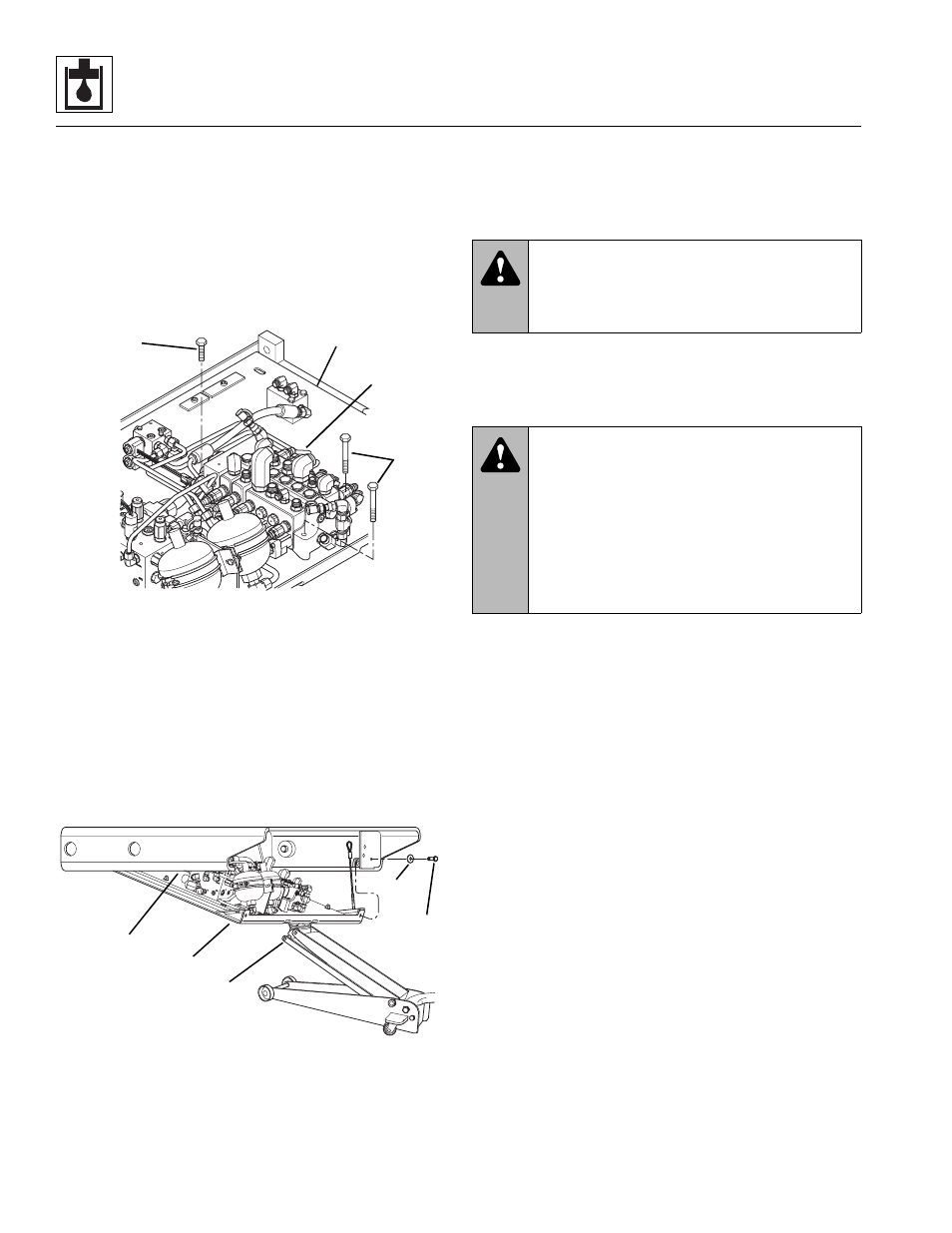

Main Control Valve Installation

1. Place the assembled main control valve (1) into

position on the valve plate assembly (2) aligning the

three bolt holes with the main control valve holes.

2. Insert the two long capscrews (3) and the short

capscrew (4) through the valve and tighten into the

weldnuts of the valve plate assembly. Torque all

three capscrews to 13-23 lb-ft (17-31 Nm).

3. Use new oiled o-rings as required. Reattach and

secure all hoses, clamps, etc. to the main control

valve (1).

4. Using the floor jack (5) raise the sub plate, w/valve

plate assembly (6), up into position.

5. Line up the mounting holes in the cab support (7)

and the holes in the sub plate (6). Secure in place

with the capscrews (8) and flat washers (9). Torque

the capscrews to 43-78 lb-ft (59-106 Nm).

6. Reassemble the step. Refer to Section 4.6, “Cab

Installation,” for step assembly procedures.

7. Check the routing of all hoses, wiring and tubing for

sharp bends or interference with any rotating

members, and install tie wraps and/or protective

conduit as required. Tighten all tube and hose

clamps.

8. Start the engine and run at approximately one-third

to one-half throttle for about one minute without

moving the vehicle or operating any hydraulic

functions.

9. Inspect for leaks and check the level of the hydraulic

fluid in the reservoir. Shut the engine OFF.

Note: Check for leaks and repair as required before

continuing. Add hydraulic fluid to the reservoir as

needed.

10. Wipe up any hydraulic fluid spillage in, on, near and

around the vehicle, work area and tools.

g. Main Control Valve Test

Conduct a pressure check of the hydraulic system in its

entirety. Adjust pressure(s) as required. Refer to Section

8.7, “Hydraulic System Testing.”

MU3870

1

2

3

4

MU3820

5

6

7

8

9

WARNING:

Avoid prolonged engine

operation in closed areas with inadequate

ventilation. Failure to properly ventilate exhaust

fumes can result in death or serious injury.

WARNING:

Hydraulic oil leaking under

pressure can penetrate the skin and cause

severe personal injury. DO NOT use your hand

or any part of your body to check for hydraulic

leaks. When checking for hydraulic leaks, wear

safety glasses and gloves to help provide

protection from spraying hydraulic oil. Use a

piece of cardboard or paper to search for

leaks.