Lull 944E-42 Service Manual User Manual

Page 472

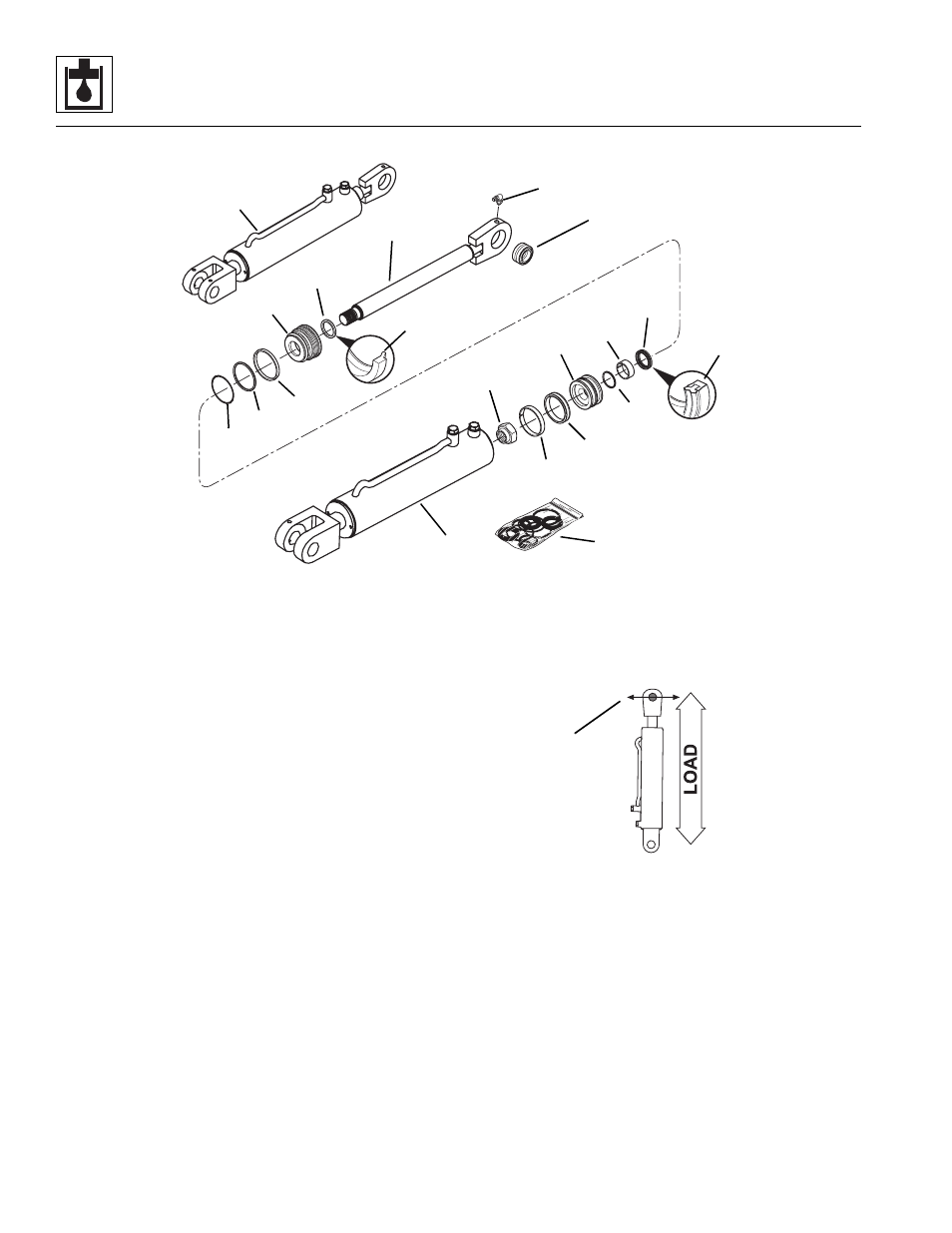

Hydraulic System

8.220

Model 644E-42/944E-42

Rev. 6/04

Note: If a white, powdery residue remains on the

threads and parts, clean the residue away with a soft

brass wire brush prior to reassembly, and wipe with

Loctite “T” cleaner before proceeding.

7. Apply Loctite Threadlocker #271 (red) to the

locknut (11). Thread the locknut onto the rod (3) and

torque to 445-515 lb-ft (603-698 Nm). The threads

will deform upon tightening, locking the nut in place.

8. Install the capped T-seal (10) and precision

wearband (9) onto the piston (5).

Note: The T-seal actually consists of four components; a

wide, flexible inner band, the flexible T-seal band itself,

and two supportive split caps that mount on either side of

the “T” itself.

9. Install new oiled o-ring (6), back-up ring (7) and

locking insert (8) onto the head gland (4).

IMPORTANT: When sliding the rod and piston assembly

in the tube, prevent the threaded end of the tube from

damaging the piston (5). Keep the rod centered within

the tube to help prevent binding. Protect the finish on the

rod at all times. Damage to the surface of the rod can

cause seal failure.

10. Carefully insert the rod (3), with all attachments,

straight into the tube (2).

11. Using a pin spanner wrench, thread the head

gland (4) into the tube (2). Torque the head gland to

250-300 lb-ft (339-407 Nm).

12. Install the bearing (20) into the rod end. When

installing the bearing, the fracture in the bearing race

must be positioned perpendicular (21) to the force of

the load.

f.

Slave Cylinder Installation

1. Align the slave cylinder with its mounting bosses on

the transfer carriage.

2. Align the mount pin bolt holes with the slave cylinder

mount holes. Refer to Section 3.3.3, “Outer Boom

Replacement,” and Section 11.3.2, “Transfer

Carriage Installation,” to install the slave cylinders.

3. Refer to Section 2.3, “Torques,” for fitting torque

values.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

MU3570

20

MU4560

21