Hydraulic system – Lull 944E-42 Service Manual User Manual

Page 387

8.135

Model 644E-42/944E-42

Rev. 6/04

Hydraulic System

Not

OK

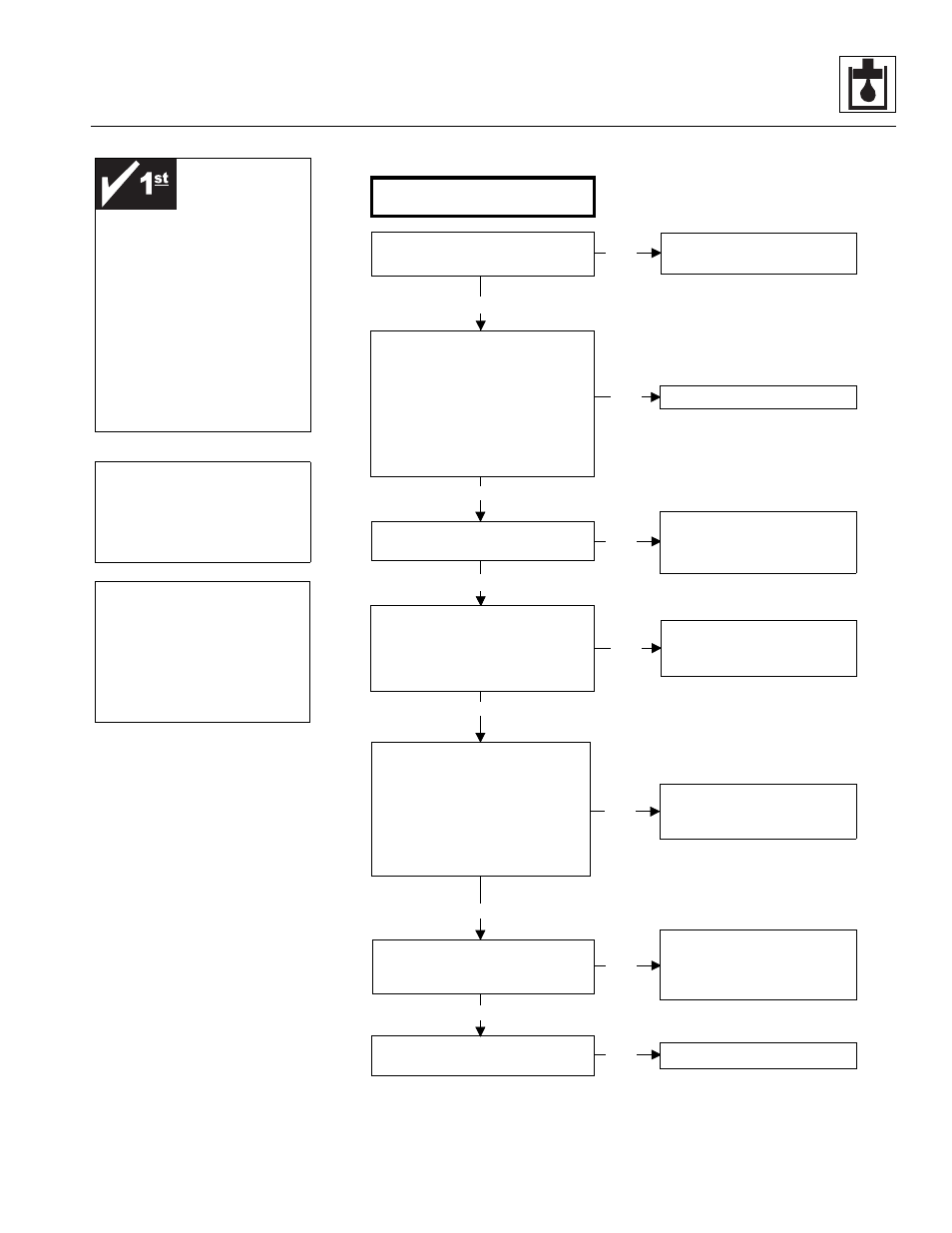

Check the flow at the end of the

circuit at the female coupler.

Repair/replace pump

NOTE:

When checking pressures in

circuits, refer to Section 8.7,

“Hydraulic System Testing,” for

correct pressure readings.

NOTE:

Before pressure checking

circuits, refer to Section 9.8.29,

Troubleshooting,” to ensure the

electrical circuits for the pilot

select valve are functioning

Not

OK

Check pilot pressure at “PPG”

port of accumulator charge/

secondary function valve.

Adjust/repair/replace

pressure reducing cartridge

on accumulator charge/

secondary function valve.

Not

OK

Check port relief at main control

valve

Replace the relief valve on

auxiliary hydraulic section of

main control valve.

There are no auxiliary hydraulic

functions.

Not

OK

Check the standby pump pressure

at implement pump pressure tap.

If OK

If OK

If OK

Replace unloader cartridge

on main control valve.

If OK

Not

OK

Adjust/replace main relief

cartridge on main control

valve.

If OK

Not

OK

Repair/replace front joystick.

Install pressure gauge in the pilot

supply line, between the rear

joystick and the extend/retract

section of main control valve.

Check pilot pressure. With the

joystick moved all the way to the

right, the pressure should be

444 ±22 psi (30,6 ±1,5 bar).

Check the main relief pump

pressure at implement pump

pressure tap. Refer to Section 8.7,

“Hydraulic System Testing,” test

sequence 7.

Install pressure gauge in the pilot

supply line, between the front

joystick and the auxiliary hydraulic

section of main control valve.

Check pilot pressure. With the

button pressed and joystick moved

all the way to the right the

pressure should be 444 ±22 psi

(30,6 ±1,5 bar).

Not

OK

Inspect pump. Refer to

Hydraulic Testing

Check the cycle times for boom

LIFT and boom EXTEND to

determine pump performance.

Pump flow directly controls these

cycle times. Refer to Section

Performance Specifications,” for

correct cycle times.

If OK

Before troubleshooting any

hydraulic circuit, ALWAYS

begin by checking the

following:

1. Hydraulic oil level in the

reservoir

2. All hoses, tubes, fittings

for leaks, kinks,

interference, etc.

3. Air in the lines