Caution, Hydraulic system – Lull 944E-42 Service Manual User Manual

Page 282

Hydraulic System

8.30

Model 644E-42/944E-42

Rev. 6/04

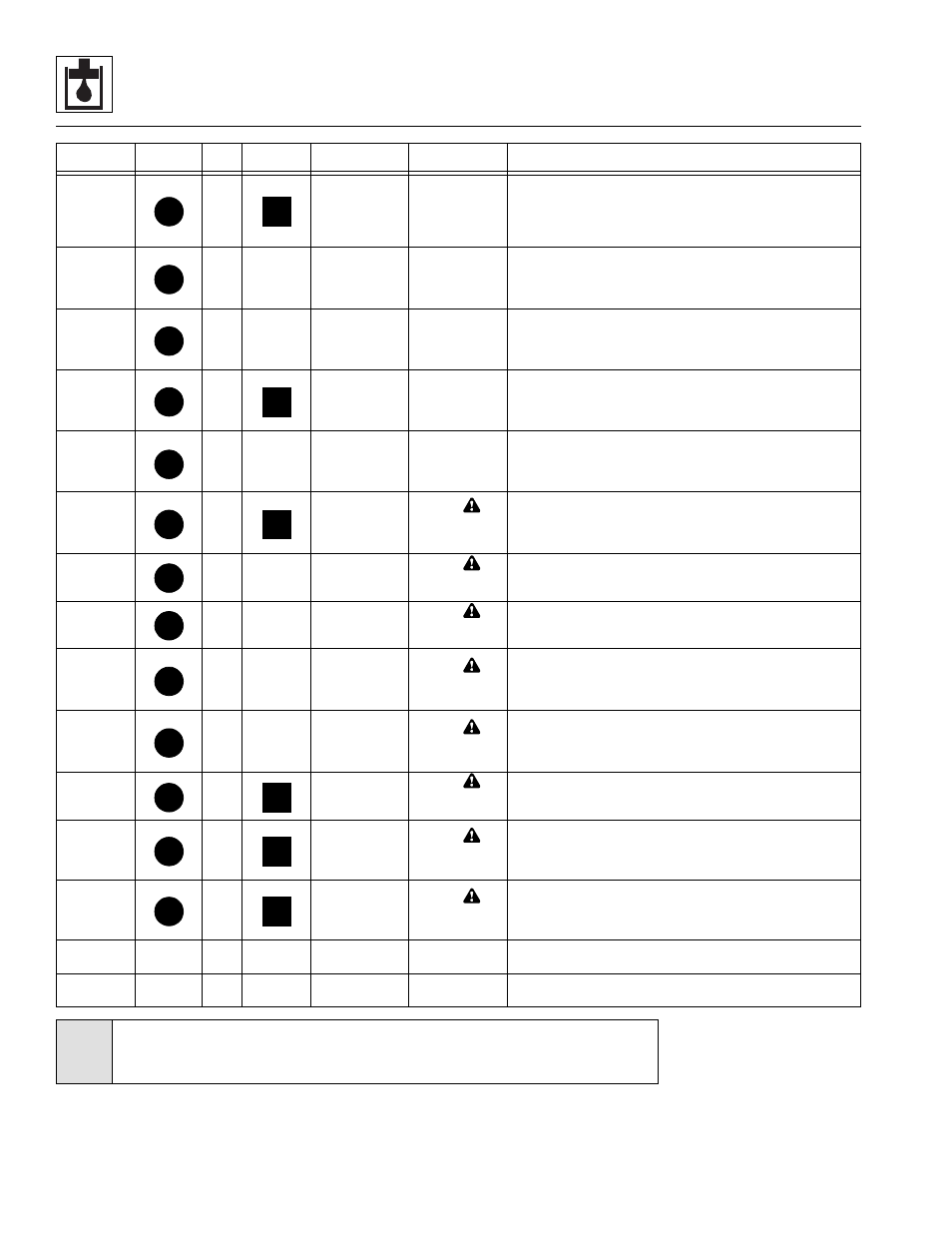

TEST

SEQUENCE

TEST

LOCATION

Valve

Port

ADJUST.

LOCATION

COMPONENT

DESCRIPTION

PRESSURE

READINGS

PRESSURE TEST PROCEDURES

8

—

Auxiliary

Hydraulics

2,900-3,100 psi

(200-214 bar)

With engine at high idle, use the auxiliary hydraulic control lever

to check pressure to both male and female connectors. Hold

over relief and check pressure. If pressure is incorrect, adjust or

replace cartridge located in the auxiliary section of the main

control valve.

9

—

N/A

Main Valve Port

Relief

Attachment Tilt

Backward

3,400-3,600 psi

(234-248 bar)

CONSULT FACTORY

10

—

N/A

Main Valve Port

Relief

Attachment Tilt

Forward

3,400-3,600 psi

(234-248 bar)

CONSULT FACTORY

11

—

Main Valve Port

Relief Boom

Extend

2,900-3,100 psi

(200-214 bar)

With engine at high idle, use the boom extend lever to fully

extend the boom. Hold over relief and check pressure. If

pressure is incorrect, check the main system pressure using

test sequence 7.

12

—

N/A

Main Valve Port

Relief Transfer

Carriage

Forward

3,400-3,600 psi

(234-248 bar)

With engine at high idle, use the transfer carriage lever to fully

extend the transfer carriage. Hold over relief and check

pressure. If pressure is incorrect, check the main system

pressure using test sequence 7

13

—

Main Valve Port

Relief Transfer

Carriage Back

See

2,400-2,600 psi

(165-179 bar)

With engine at high idle, use the transfer carriage lever to fully

retract the transfer carriage. Hold over relief and check

pressure. If pressure is incorrect, adjust or replace cartridge

located in the transfer section of the main control valve.

14

—

N/A

Brake Valve

(Service Brake

Pressure)

See

450-550 psi

(31-38 bar)

With engine at idle, depress and hold brake pedal. Check

pressure for the front axle. If pressure is incorrect, check

accumulator pressure using test sequence 6.

15

—

N/A

Brake Valve

(Service Brake

Pressure)

See

450-550 psi

(31-38 bar)

With engine at idle, depress and hold brake pedal. Check

pressure for the rear axle. If pressure is incorrect, check

accumulator pressure using test sequence 6.

16

—

N/A

Brake Valve

(Service Brake

Accumulator

Pressure)

See

450-550 psi

(31-38 bar)

With engine OFF, depress and hold brake pedal. Check

pressure for the front axle. If pressure is incorrect, check for

external leaks. If no leaks are found, check accumulator

pressure using test sequence 6.

17

—

N/A

Brake Valve

(Service Brake

Accumulator

Pressure)

See

450-550 psi

(31-38 bar)

With engine OFF, depress and hold brake pedal. Check

pressure for the rear axle. If pressure is incorrect, check for

external leaks. If no leaks are found, check accumulator

pressure using test sequence 6.

18

G1

Stabilizer

Cylinder

See

75-150 psi

(5,2-10,3 bar)

With the engine at idle, check the pressure on the cylinder. If the

pressure is not correct, adjust or replace the cartridge located

on the stabilizer cylinder block.

19

G1

Stabilizer

Cylinder

See

50 psi min.

(3,4 bar) min.

With the engine at idle and boom below 40°, frame sway all the

way to the right, check the pressure on the cylinder. If the

pressure is not correct, adjust or replace the cartridge located

on the stabilizer cylinder block.

20

G1

Stabilizer

Cylinder

See

200 psi max.

(13,8 bar) max.

With the engine at idle and boom below 40°, frame sway all the

way to the left, check the pressure on the cylinder. If the

pressure is not correct, adjust or replace the cartridge located

on the stabilizer cylinder block.

—

A

—

—

Load Sense

(Steering)

—

Consult with JLG Technical Service Department for additional

testing information.

—

B

—

—

Load Sense

(Implement)

—

Consult with JLG Technical Service Department for additional

testing information.

2

4

2

2

2

5

2

2

6

7

8

7

8

9

7

9

7

9

7

CAUTION:

GAUGE DAMAGE may occur. Malfunctioning hydraulic system circuits may have

excessive pressure and can cause hydraulic pressure spikes. Test circuit with the highest reading

pressure gauge first. If this gauge cannot record an accurate pressure reading, use the next lower

pressure gauge.