Fuel filter replacement, Bleeding air from the fuel system, Section 7.8.6, “bleeding air from the fuel system – Lull 944E-42 Service Manual User Manual

Page 229: Warning, Caution

7.27

Model 644E-42/944E-42

Rev. 6/04

Engine: Cummins 4BT 3.9, B4.5T and QSB 4.5T

7.8.5

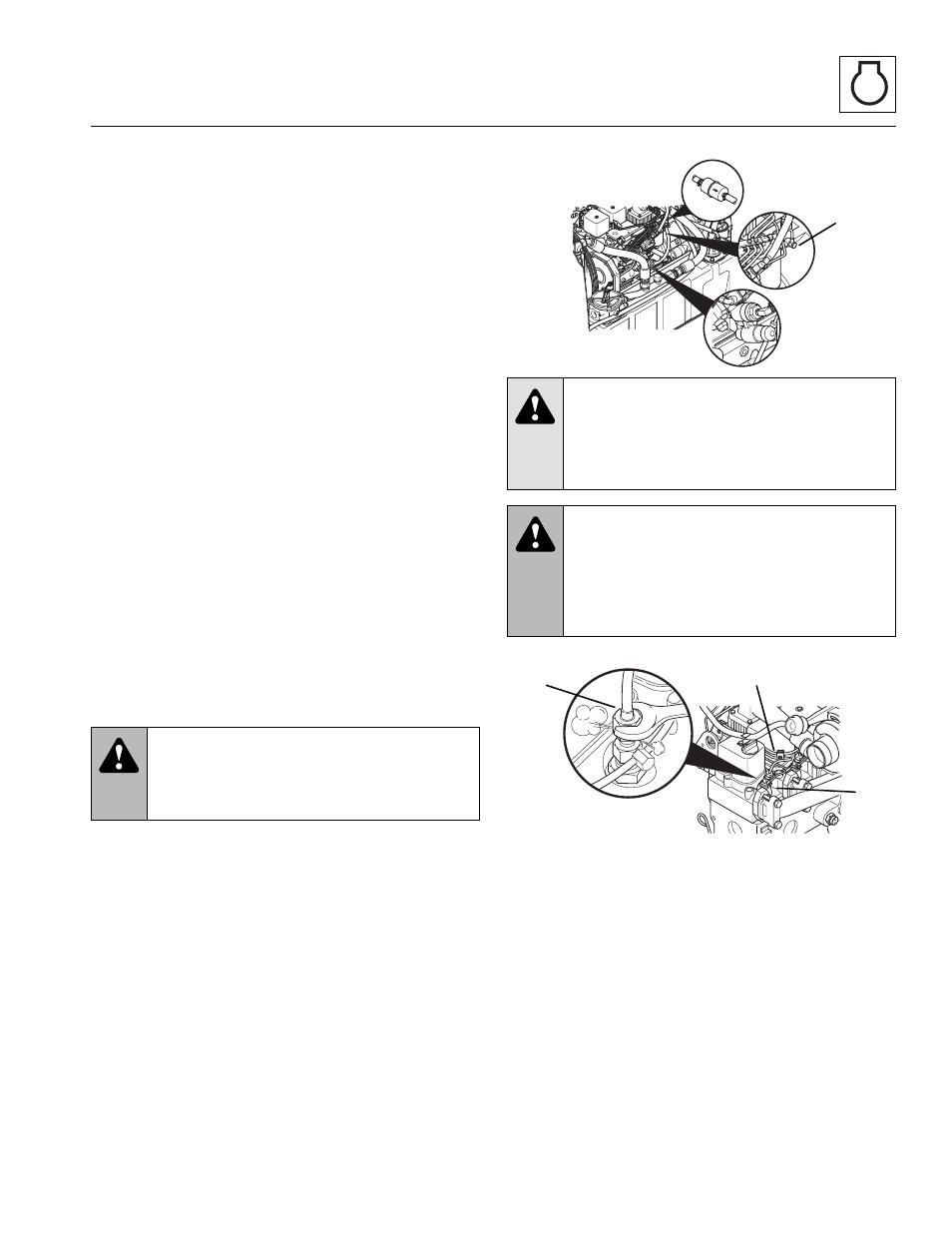

Fuel Filter Replacement

The fuel filter (4 or 9) must be changed at shorter

intervals with evidence of water or contaminated fuel.

1. Unlatch and open the engine cover.

2. Clean around the fuel filter head (4 or 9).

3. Unscrew the fuel filter and dispose of properly.

4. Clean the gasket surface of the filter head and

replace the o-ring.

5. Fill the new fuel filter with clean No. 2 diesel fuel.

6. Lubricate the o-ring seal with clean No. 2 diesel fuel.

7. Install the fuel-filled filter and hand tighten. DO NOT

overtighten.

NOTE: Mechanical over-tightening may distort the

threads or damage the sealing ring.

8. Close and latch the engine cover.

Controlled venting is provided at the injection pump

through the fuel drain manifold. Small amounts of air

introduced by changing the fuel filter element will be

vented automatically as long as the element was filled

with fuel prior to installation.

7.8.6

Bleeding Air From The Fuel System

Air must be vented from the fuel system whenever any

component between the fuel tank and the injection pump

has been disconnected, or when the system has been

emptied or run out of fuel.

IMPORTANT! DO NOT attempt to start the engine until

the injection pump has been filled and primed with fuel.

Serious damage to the lift pump will result due to lack of

proper lubrication.

1. To vent the low pressure lines and fuel filter, open

the vent screw (17) located on the filter head.

2. Operate the hand plunger (3 or 8) on the lift pump (2

or 7) until fuel flowing from the fitting is free of air.

3. Tighten the vent screw (17) and torque to 7 lb-ft

(9 Nm).

The process of venting high pressure fuel lines involves

energizing the starter motor to rotate the crankshaft

which will, in turn, pump any unwanted air from the fuel

lines.

4. To vent the high pressure fuel lines (18), loosen one

fitting (19) at the injector (20).

5. Turn the ignition switch to the START position and

crank the engine for a maximum of 15 seconds or

until fuel, free of air, comes out of the injector fitting.

6. Tighten the fitting. Torque to 22 lb-ft (30 Nm).

7. Repeat Steps 4 thru 6 for each fitting until the engine

runs smoothly.

With the engine running, visually check for leaks. Turn

ignition switch OFF.

WARNING:

DO NOT bleed the fuel sys-

tem of a hot engine. Doing so could create a

fire hazard. Allow the engine to cool before

bleeding the fuel system.

CAUTION:

When using the starting

motor to vent the fuel system, DO NOT

energize the starter solenoid or crank the

engine for more than 15 seconds at a time;

wait two minutes between engagements.

WARNING:

KEEP CLEAR of spraying

fuel. Fuel can spray when venting high

pressure lines. The fuel pressure is sufficient

to penetrate the skin and cause serious bodily

injury. Wear protective clothing and safety

glasses.

OU0940

17

OU0250

18

19

20