Warning – Lull 944E-42 Service Manual User Manual

Page 117

4.13

Model 644E-42/944E-42

Rev. 6/04

Cab and Covers

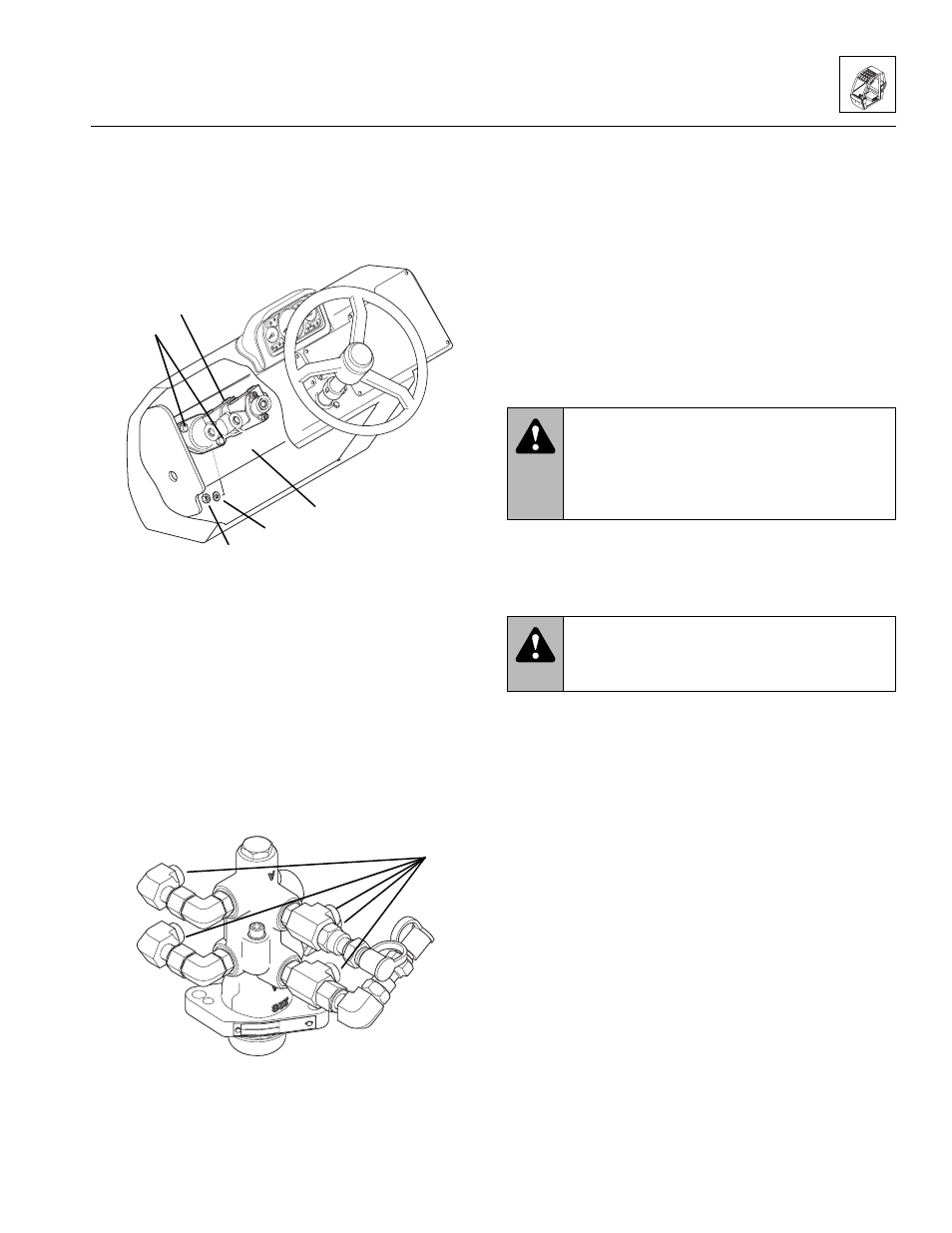

6. Remove the two capscrews (4), flat washers (5) and

nuts (6) attaching the service brake valve (7) to the

steering column support (8). Remove the service

brake valve (7) through the lower dash panel

opening.

b. Brake Valve Installation

Note: DO NOT disassemble the service brake valve.

The service brake valve is not serviceable and must be

replaced as a unit.

Note: Use new oiled o-rings as required. ALWAYS

replace seals, o-rings, gaskets etc., with new parts to

help ensure proper sealing and operation. Lubricate

seals and o-rings with clean hydraulic fluid.

Note: Torque all the fittings as specified in Section 2.3,

“Torques.”

1. Transfer the fittings (9) to the new brake valve. Note

the orientation of each fitting before removing them.

2. Install the service brake valve (7) through the lower

dash panel opening. Mount the brake valve to the

steering column support (8) inside the dash. Attach

the brake valve with two capscrews (4), flat washers

(5) and flange nuts (6).

3. Attach the hydraulic hoses to the service brake

valve.

4. Check the routing of all hoses, wiring and tubing for

sharp bends or interference with any rotating

members, and install tie wraps and/or protective

conduit as required.

5. Start the engine and run at approximately one-third

to one half throttle for about one minute without

moving the vehicle or operating any hydraulic

functions.

6. Inspect the service brake valve and connections for

leaks and check the level of the hydraulic fluid in the

reservoir. Shut the engine OFF.

Note: Check for leaks and repair as required before

continuing. Add hydraulic fluid to the reservoir as

needed.

7. Wipe up any hydraulic fluid spillage in, on, near and

around the vehicle work area and tools.

Note: Refer to Section 8.7, “Hydraulic System Testing,”

for complete testing procedure.

MU3411

~

4

6

7

8

5

9

MU3500

WARNING:

Avoid prolonged engine

operation in closed areas with inadequate

ventilation. Failure to properly ventilate

exhaust fumes can result in death or serious

injury.

WARNING:

Wait for the hydraulic fluid

to cool before servicing any hydraulic component.

Hot hydraulic oil can cause severe burns.