Warning – Lull 944E-42 Service Manual User Manual

Page 448

Hydraulic System

8.196

Model 644E-42/944E-42

Rev. 6/04

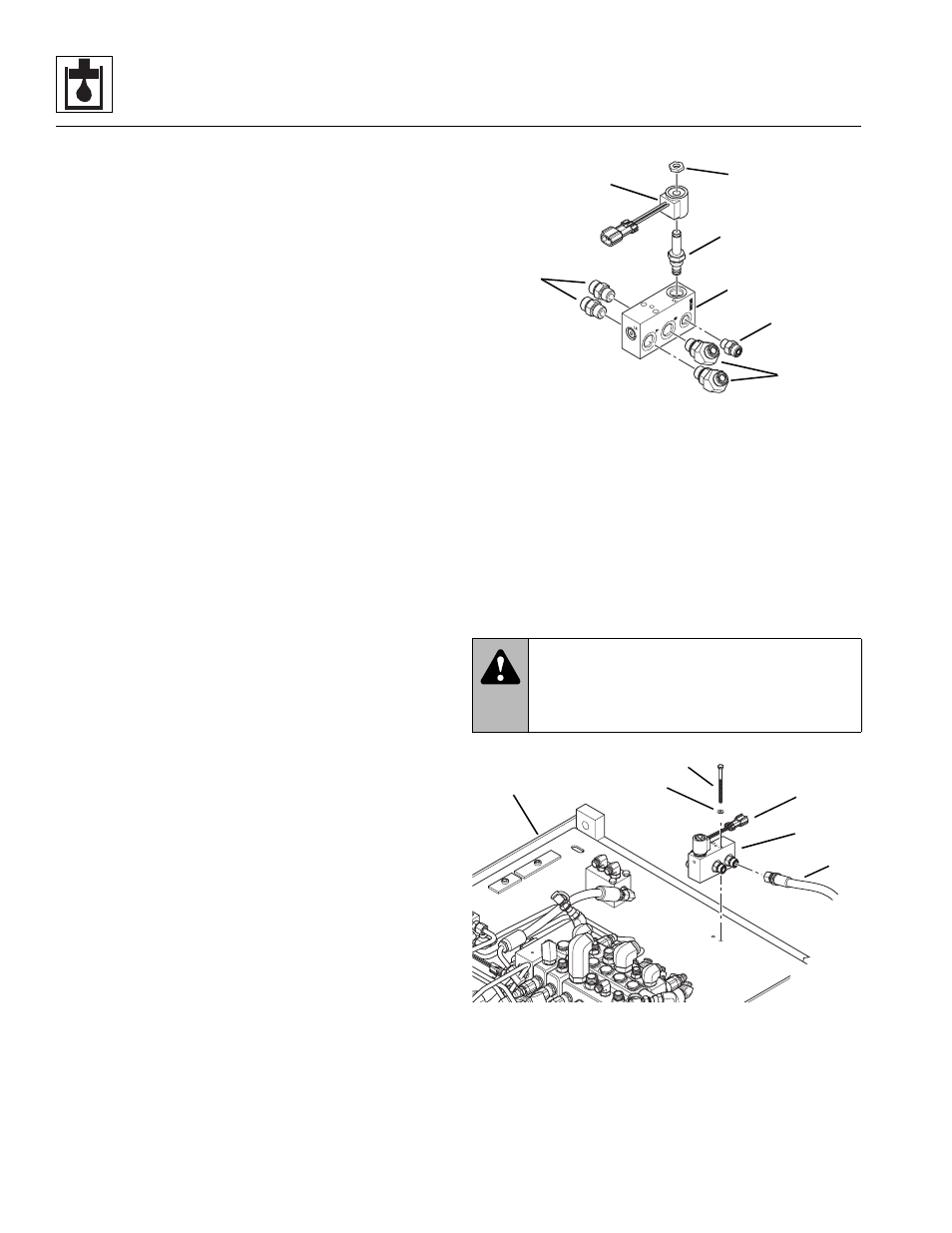

b. Auxiliary Hydraulic Pressure Release Valve

Disassembly, Inspection and Reassembly

Note: Use new oiled o-rings as required. ALWAYS

replace seals, o-rings, gaskets, etc., with new parts to

help ensure proper sealing and operation. Lubricate

seals and o-rings with clean hydraulic oil.

Note: Torque all the fittings as specified in Section 2.3,

“Torques.”

1. Remove the elbow fittings (1) from the “A” and “B”

ports on the valve block (2).

2. Remove the straight fittings (3) from the “A” and “B”

ports on the valve block and the “Drain” port (4).

3. Remove the solenoid cartridge (5) from the valve

block.

4. Clean all components with a suitable cleaner before

inspection.

5. Inspect internal passageways of the auxiliary

hydraulic pressure release valve and its component

parts for wear, damage, etc. If inner surfaces of the

auxiliary hydraulic pressure release valve DO NOT

display an ultra-smooth, polished finish, or

components are damaged in any way, replace the

auxiliary hydraulic pressure release valve or

appropriate part. Often, dirty hydraulic fluid causes

failure of internal seals and damage to the polished

surfaces within the auxiliary hydraulic pressure

release valve.

6. Secure the auxiliary hydraulic pressure release valve

block (2) in a bench vise or by other suitable means.

7. Install the elbow fittings (1) into port “A” and “B” on

the valve block. Torque to 50-60 lb-ft (67-81 Nm).

8. Install the straight fittings (3) into port “A” and “B” on

the valve block. Torque to 50-60 lb-ft (67-81 Nm).

9. Install a straight fitting (4) into port “Drain” on the

valve block. Torque to 24-26 lb-ft (32-35 Nm).

10. Install the solenoid cartridge (5) into the valve block.

Torque the solenoid (6) to 20 lb-ft (27 Nm). Torque

the solenoid nuts (7) to 5 lb-ft (7 Nm).

c. Auxiliary Hydraulic Pressure Release Valve

Installation

1. Position the auxiliary hydraulic pressure release

valve (8) back onto the valve plate (9).

2. Replace the two capscrews (10) and washers (11)

through the auxiliary hydraulic pressure release

valve (8) and secure to the valve plate (9). Torque

the two capscrews to 5-9 lb-ft (7-12,5 Nm).

3. Reattach and secure all hoses (12) and fittings.

4. Reconnect the wire harness connector (13).

WARNING:

Avoid prolonged engine

operation in closed areas with inadequate

ventilation. Failure to properly ventilate exhaust

fumes can result in death or serious injury.

MU5890

1

2

3

4

5

6

7

B

A

MU5840

12

8

13

10

9

11