Torques, Sae flat face o-ring seal hydraulic fittings – Lull 944E-42 Service Manual User Manual

Page 21

2.5

Model 644E-42/944E-42

Rev. 6/04

General Information, Specifications and Maintenance

2.3

TORQUES

2.3.1

SAE Flat Face O-Ring Seal

Hydraulic Fittings

a. Assembly Procedure

Improper assembly of this type of joint will result in

leaking joints. Under tightening will result in the joint

loosening during normal usage. Foreign material on

either seal surfaces will cause damage to one or both

mating parts when the joint is tightened resulting in a

leaking joint. The absences of the fitting o-ring will cause

the joint to leak.

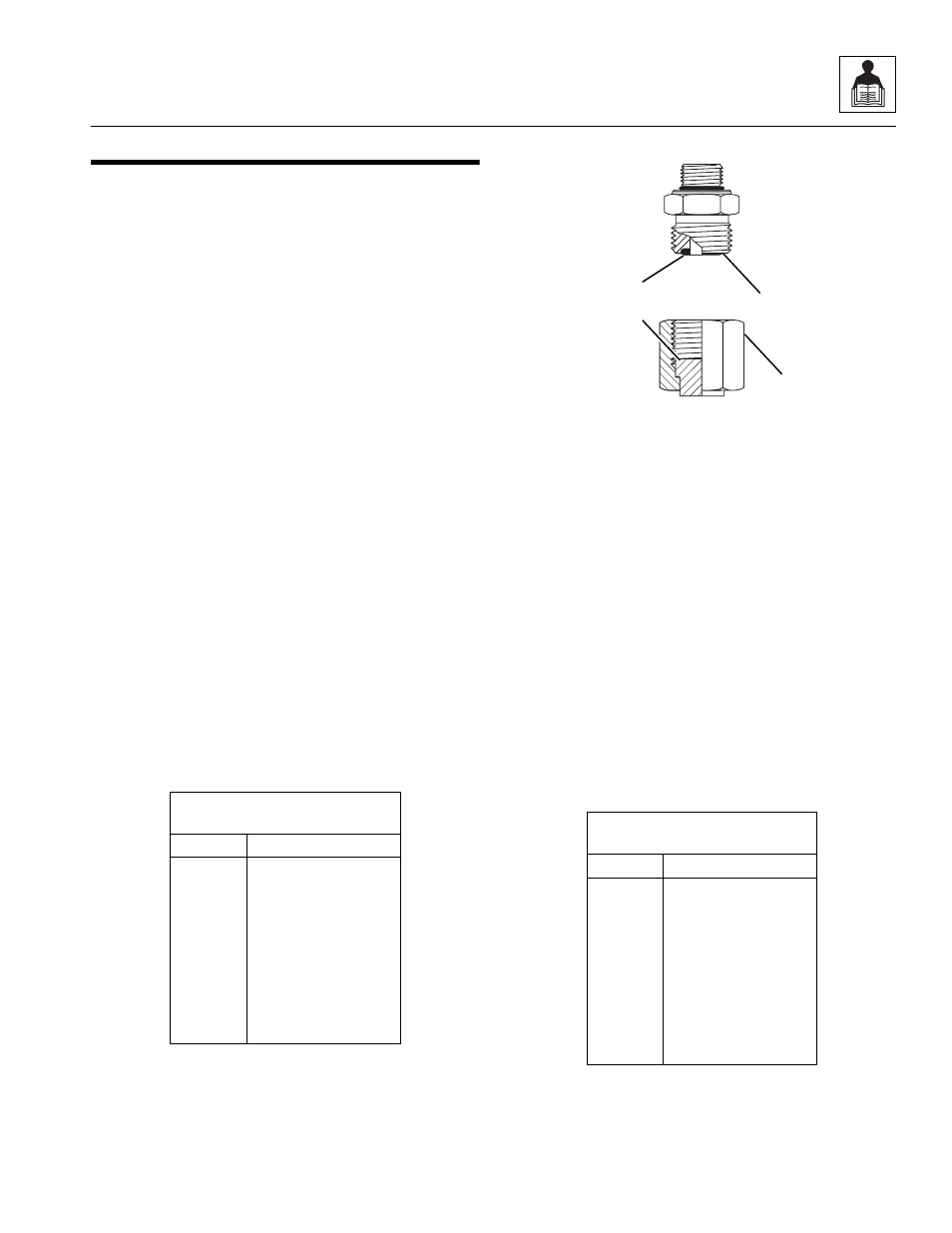

1. Inspect both the male (2) and female (3) sealing

surfaces for burrs, scratches, dents, other damage,

or foreign material. If any damage is found on either

surface, the part is to be rejected as unusable. Clean

off any foreign material from the sealing surfaces

before assembly.

2. Inspect the male fitting for the presence of the seal

o-ring (4). Inspect the o-ring for any sign of damage.

If the o-ring is missing or damaged replace it.

3. Apply clean petroleum based oil to the male thread.

4. Place the flat surface of the female connector (2) in

full contact with the o-ring (4) in the male connector.

5. Finger tighten the nut (5) onto the fitting.

6. Complete the joint by tightening the nut

to the torque

specified in the table. For hoses and swivel fittings

use a second wrench to keep the female connector

from moving during tightening.

b. Straight O-Ring Boss Fittings To

O-Ring Boss Ports

Improper assembly of this joint will result in leaking joints.

Under tightening of the fitting will result in the fitting

loosening during normal operation and the joint leaking.

Damaging the o-ring during assembly will result in

immediate joint leakage.

1. Inspect components to ensure that male and female

port threads and sealing surfaces are free of burrs,

nicks, or scratches, or any foreign material. If any

damage is found the malfunctioning part must not be

used. Clean any foreign material from the mating

parts before assembly.

2. Lubricate the o-ring and male thread with a clean

petroleum based lubricant.

3. Screw the fitting into the port.

4. Torque the fitting to the values found in table.

O-Ring Boss Fittings To

O-Ring Boss Ports

SAE Size

Torque lb-ft (Nm)

4

19 ± 5 (26 ± 7)

6

35 ± 5 (47 ± 7)

8

52 ± 7 (70 ± 10)

10

83 ± 17 (112 ± 23)

12

120 ± 20 (163 ± 27)

16

165± 35 (224 ± 47)

20

215 ± 65 (292 ± 88)

24

252 ± 77 (342 ± 104)

O-Ring Boss Fittings To

O-Ring Boss Ports

SAE Size

Torque lb-ft (Nm)

4

15 ± 1 (20 ± 1)

6

25 ± 1 (34 ± 1)

8

55 ± 5 (75 ± 7)

10

76 ± 5 (103 ± 7)

12

130 ± 5 (176 ± 7)

16

210± 10 (285 ± 14)

20

245 ± 35 (332 ± 47)

24

315 ± 45 (427 ± 61)

2

MA10,0800

3

4

5