Warning – Lull 944E-42 Service Manual User Manual

Page 261

8.9

Model 644E-42/944E-42

Rev. 6/04

Hydraulic System

a. Disconnection Procedure

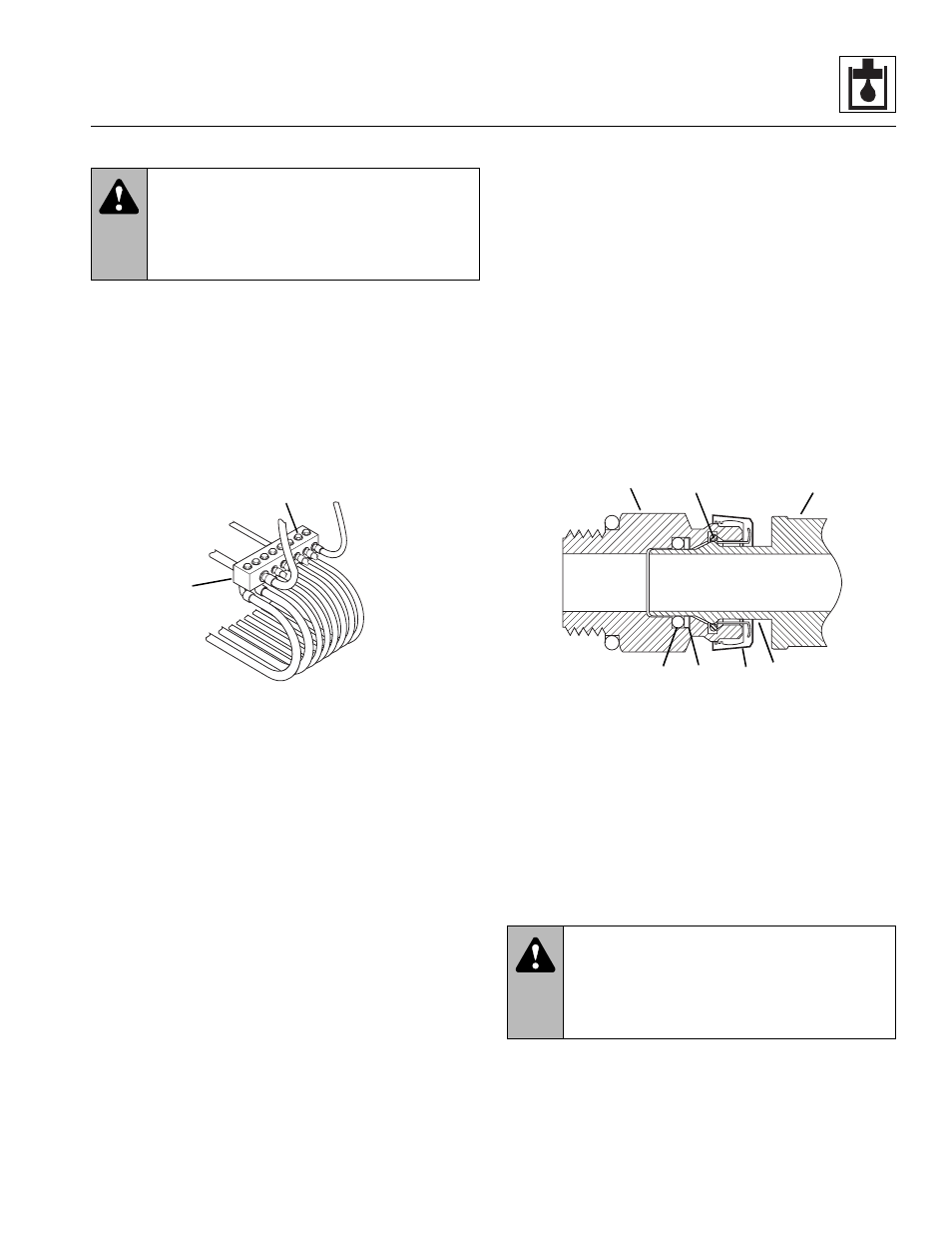

1. Relieve the hydraulic pressure in the appropriate

circuit before attempting to disconnect any of these

snap lock fittings. Refer to Section 8.2, “Safety

Information,” “To Relieve Hydraulic Pressure.” To

relieve the pressure, slowly loosen the appropriate

bleed plug (4) on the top of the block (5) directly

inline with the circuit being disconnected. Tighten

the bleed plug after the pressure has been released.

Torque the plugs to 14-16 lb-ft (19-22 Nm).

2. Clean the area around the snap lock fittings prior to

disconnection.

3. To help prevent damage to the release sleeve (6),

create a release tool insertion gap (7) by moving the

sleeve in the release direction. This can be done by

hand or by using a single prong on the release tool.

4. Insert the release tool behind the release sleeve and

pull the hose assembly out from the mating

connector. DO NOT pry on the fitting with the

release tool.

5. If a release tool is not available, a thin blade

screwdriver may be used to release the lockring (8).

Care must be used to avoid damage to the release

sleeve.

b. Inspection

These fittings are designed to be connected and

disconnected repeatedly without replacing the o-ring (9)

or back-up ring (10) unless leakage or damage is

observed.

1. Inspect both the male (11) and female (12)

connectors to ensure they are in good condition, free

of nicks, scratches and contamination. If damage is

observed the fittings need to be replaced.

2. If the o-ring (9) or back-up ring (10) are damaged

they can be replaced. Refer to the parts manual for

ordering the appropriate kit.

3. Check the wire lockring (8) to be sure it is in the

proper position in the female connector, prior to

installation or reconnection of the fittings.

c. Connection Procedure

1. Align the fitting on the hose with the mating

connector. Push the fitting straight into the mating

connector until you feel a definite snap and you feel

a solid stop.

2. Pull back on the hose assembly to verify that a

proper connection has been made and the two

fittings are securely locked together.

3. Clear the area around the roll back hoses of all

personnel.

4. After all hose connections are complete, start the

engine and SLOWLY function the boom cylinders

(lift/lower, extend/retract and attachment tilt) and the

auxiliary hydraulic to verify that a good snap lock

connection has been made.

WARNING:

Relieve hydraulic pressure

before servicing any hydraulic component.

Escaping hydraulic fluid under pressure can

penetrate the skin causing death or serious

injury.

4

5

MU0430

WARNING:

Before checking hose

connections, clear the area of all personnel.

Escaping hydraulic fluid under pressure can

penetrate the skin causing death or serious

injury.

MU0440

6

7

8

9

10

11

12