Lull 944E-42 Service Manual User Manual

Page 480

Hydraulic System

8.228

Model 644E-42/944E-42

Rev. 6/04

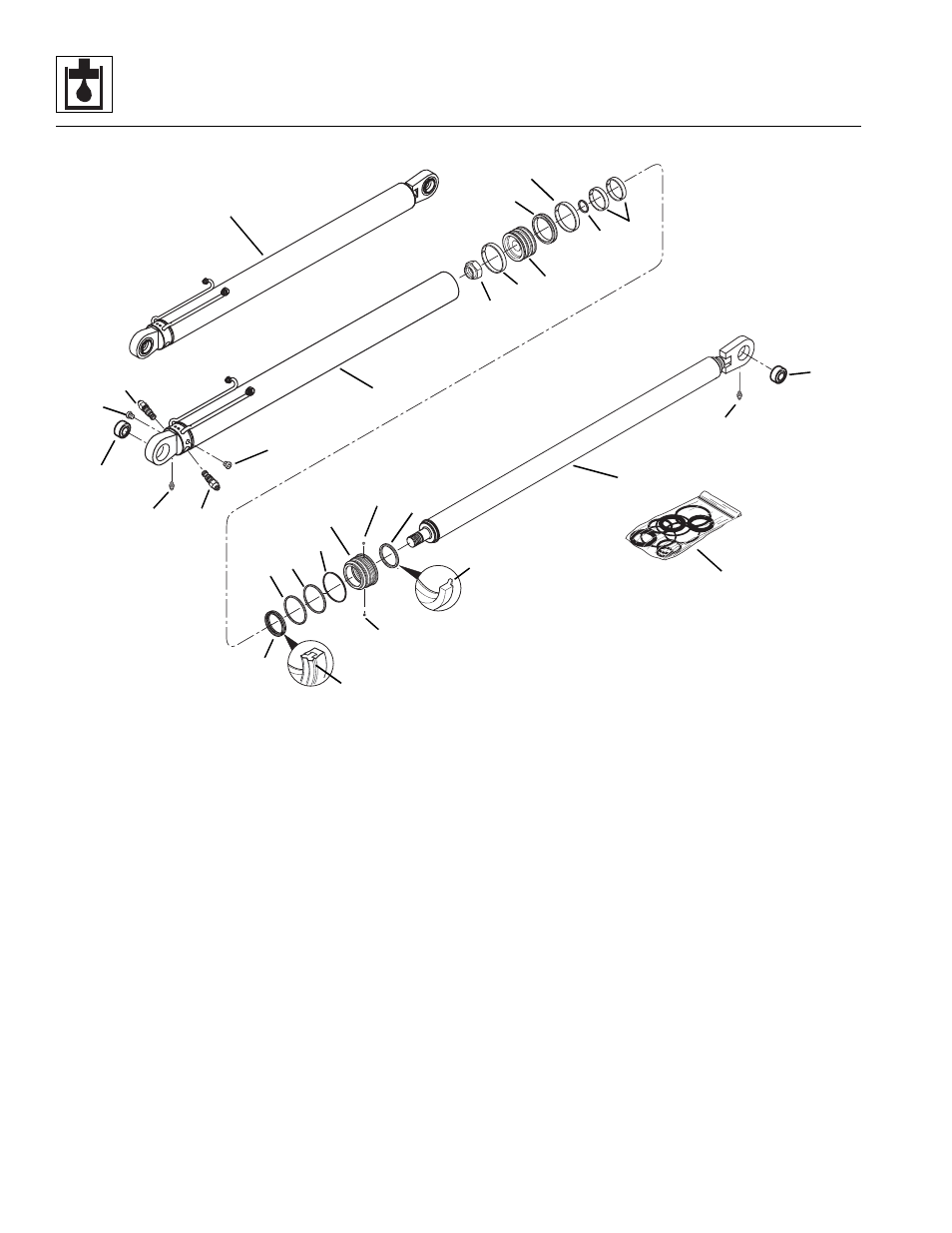

d. Lift/Lower Cylinder Inspection

1. Inspect internal surfaces and all parts for wear,

damage, etc. If inner surface of the tube (2) does not

display a smooth finish, or is scored or damaged in

any way, replace the tube. Often, dirty hydraulic fluid

causes failure of internal seals and damage to the

smooth surface within the tube.

2. Remove slight scratches on the piston, rod, or inner

surface of the tube with very fine grit emery cloth. Use

the emery cloth in a rotary motion to polish out and

blend the scratch(es) into the surrounding surface.

3. Clean parts with trichlorethylene.

4. Check that the rod (8) is straight. If it is bent, install a

new rod.

e. Lift/Lower Cylinder Assembly

Note: Follow Section 8.14.3, “General Cylinder

Assembly Instructions.”

1. Install a new oiled o-ring (19), back-up ring (18) and

o-ring (17) on the head gland (10).

2. Install the sealed outside diameter heavy-duty rod

wiper (22). The wiper lip (25) should be away from

the head gland. Install the DZR seal (21), orienting

the edge (26). Install the precision wearbands (20) in

the head gland. Use tools that will not damage the

seals.

3. Install the capped T-seal (15) and both precision

wearbands (14) on the piston (11).

Note: The T-seal actually consists of four components; a

wide, flexible inner band, the flexible T-seal band itself,

and two supportive split caps that mount on either side of

the “T” itself.

4. Install a new small oiled o-ring (16) into the

piston (11).

5. Fasten the rear of the rod in a soft-jawed vise and

put a padded support below and near the threaded

end of the rod to help prevent damage to the rod.

6. Carefully slide the head gland (10) onto the rod (8).

7. Install the piston (11) on the rod (8).

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

MU3700