Troubleshooting with a digital multimeter (dmm) – Lull 944E-42 Service Manual User Manual

Page 539

9.29

Model 644E-42/944E-42

Rev. 6/04

Electrical System

Offboard Diagnostics

INSITE™, is the Windows®-based PC service/

programming/diagnostic tool for 944E-42 engine. It is

used to help troubleshoot and repair the engine with

extended fault diagnostics and processing power.

INSITE™ allows the user to view active and inactive

faults and clear the inactive faults. It provides a monitor

function that allows the service technician to monitor

measured parameters, actuator status and some

calculated values. It also provides the technician with the

capability to turn on certain drivers such as the grid

heaters and lift pump as well as running diagnostic tests

such as single cylinder cutout.

9.8.3

Troubleshooting with a Digital

Multimeter (DMM)

IMPORTANT: Circuits which include any solid-state

control modules should only be tested with a ten

megohm or higher impedance digital multimeter (DMM),

or damage could occur to the module.

A DMM should be used instead of a test lamp in order to

test for voltage in high impedance circuits. While a test

lamp shows whether voltage is present, a DMM indicates

how much voltage is present.

The ohmmeter function on a DMM shows how much

resistance exists between two points along a circuit. Low

resistance in a circuit means good continuity.

IMPORTANT: Disconnect the power feed from the

suspect circuit when measuring resistance with a DMM.

This prevents incorrect readings. DMM’s apply such a

small voltage to measure resistance that the presence of

voltages can upset a resistance reading.

Diodes and solid-state components in a circuit can cause

a DMM to display a false reading. To find out if a

component is affecting a measurement take a reading

once, then reverse the leads and take a second reading.

If the readings differ, the solid-state component is

affecting the measurement.

Following are examples of the various methods of

connecting the DMM to the circuit to be tested:

• Back probe both ends of the connector and either

hold the leads in place while manipulating the

connector or tape the leads to the harness for

continuous monitoring while you perform other

operations or test driving.

IMPORTANT: DO NOT back probe a sealed connector

or a flat wire connector.

• Disconnect the harness at both ends of the

suspected circuit where it connects either to a

component or to other harnesses.

1

2

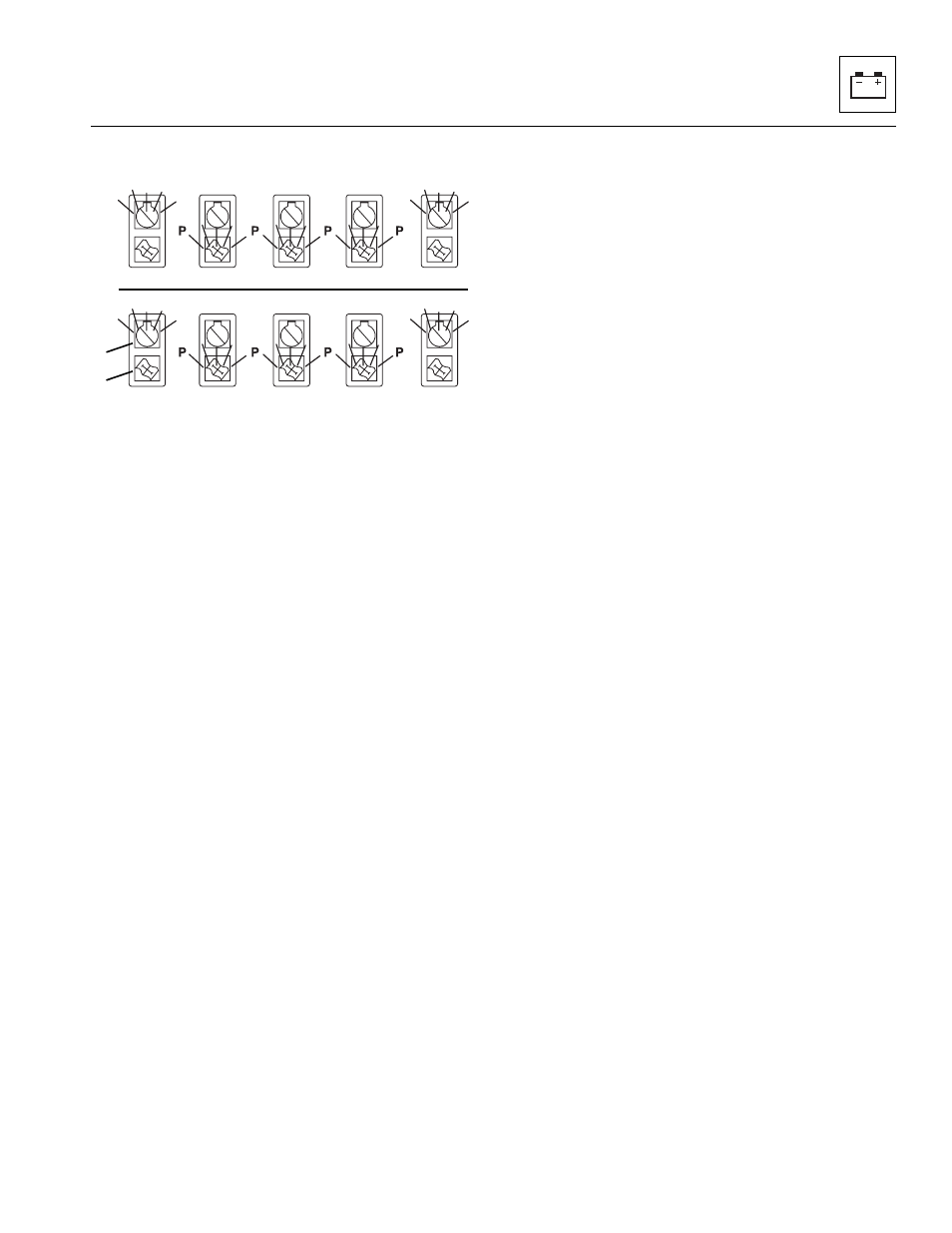

Example Fault Code Sequences

1 Blink2 Blinks4 Blinks4 Blinks1 Blink

P = Pause

Fault Code

1 Blink1 Blink1 Blink2 Blinks1 Blink

Fault Code

MU5440