After fuel system service – Lull 944E-42 Service Manual User Manual

Page 231

7.29

Model 644E-42/944E-42

Rev. 6/04

Engine: Cummins 4BT 3.9, B4.5T and QSB 4.5T

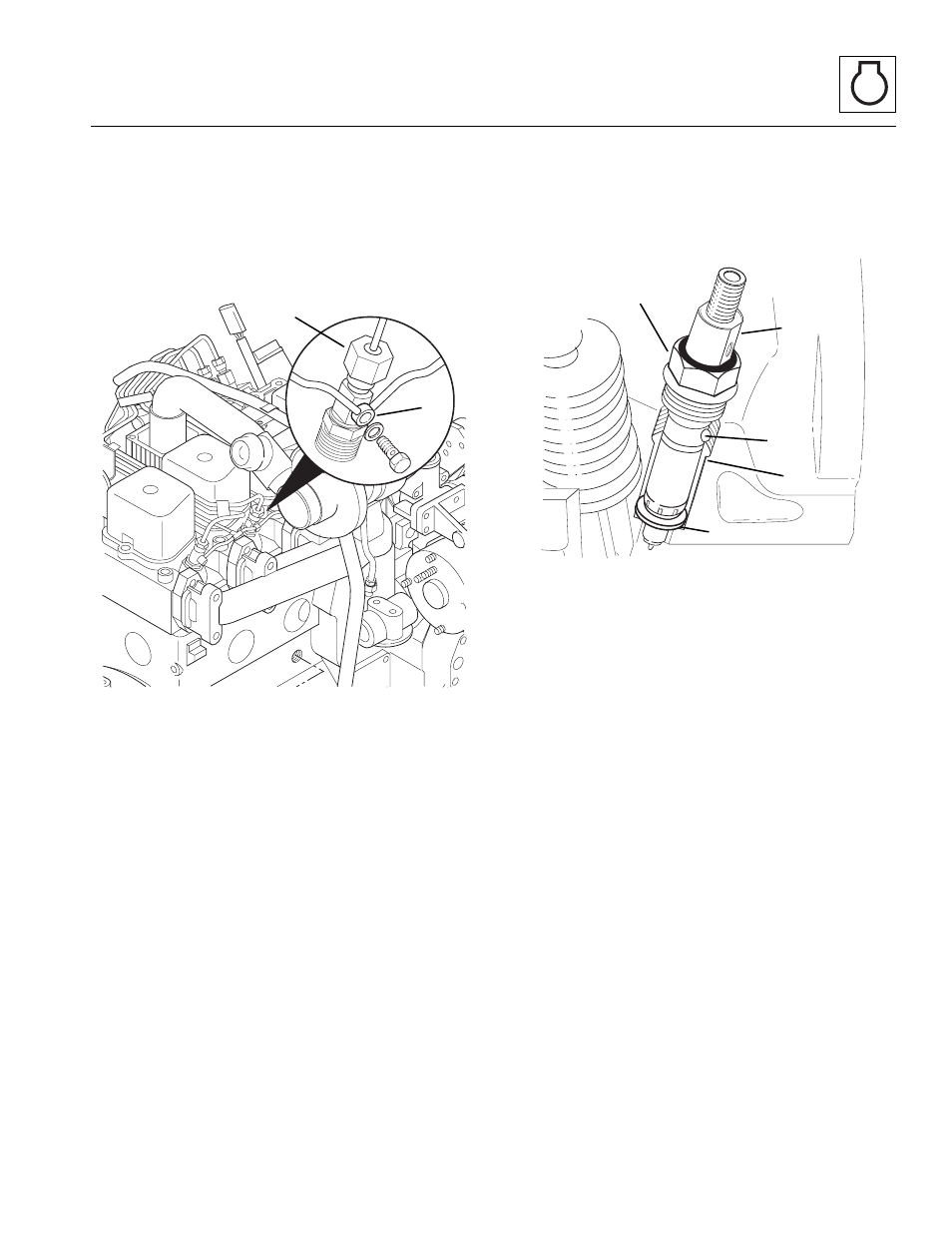

b. Injector Replacement

Preparatory steps:

• Thoroughly clean around the injector(s).

• Disconnect the high-pressure fuel lines (2).

• Disconnect the fuel drain manifold (3).

IMPORTANT: The injector must not rotate in the bore of

the cylinder head or damage to the cylinder head will

occur. If rust has formed on the hold-down nut, soak the

nut with rust-penetrating solvent for a minimum of three

minutes. Then, tap the injector body with a drift pin to

help loosen any rust.

1. Use a 16 mm wrench to prevent the injector body (4)

from turning. Loosen the hold-down nut (5) with a

24 mm box wrench.

2. Clean the injector nozzle bore.

3. Remove the injector hold-down nut from the injector

body.

4. Apply a light coat of anti-seize compound to the new

injector surface. Avoid getting anti-seize compound

into the fuel drain hole.

5. Install the hold-down (5) nut on the injector body.

6. Install a new o-ring into the recessed groove in the

top of the hold-down nut. Make sure the o-ring is not

cut or twisted during installation.

7. Apply a light coat of anti-seize compound to the

threads of the injector hold-down nut (5).

8. Assemble the injector and new copper washer (6).

Use only ONE copper washer. A light coat of clean

15W40 engine oil, placed between the washer and

the injector, will help keep the washer from falling

during installation.

9. Install the injector with the protrusion (7), on the side

of the nozzle fitting, into the notch (8), in the head.

10. Tighten the hold-down nut (5) and torque to 44 lb-ft

(60 Nm).

11. Install the fuel drain manifold (3) and torque to 6 lb-ft

(8 Nm).

12. Install the high-pressure fuel lines (2) and torque to

18 lb-ft (24 Nm).

13. Run the engine and check for fuel and air leakage.

14. Bleed the fuel system. (Refer to Section 7.8.6,

“Bleeding Air From The Fuel System.”)

7.8.8

After Fuel System Service

1. Drain and flush the fuel tank if it was contaminated.

2. Bleed air from the fuel system. (Refer to Section

7.8.6, “Bleeding Air From The Fuel System.”)

3. Fill the fuel tank with fresh, clean diesel fuel as

required.

MT3160

2

3

MA1960

4

5

6

7

8