Warning – Lull 944E-42 Service Manual User Manual

Page 501

8.249

Model 644E-42/944E-42

Rev. 6/04

Hydraulic System

18. If the bearing (17) requires replacement, support the

rod (6) in a soft-jawed vise or other suitable holding

device. Carefully press a new bearing into the rod

eyelet.

f.

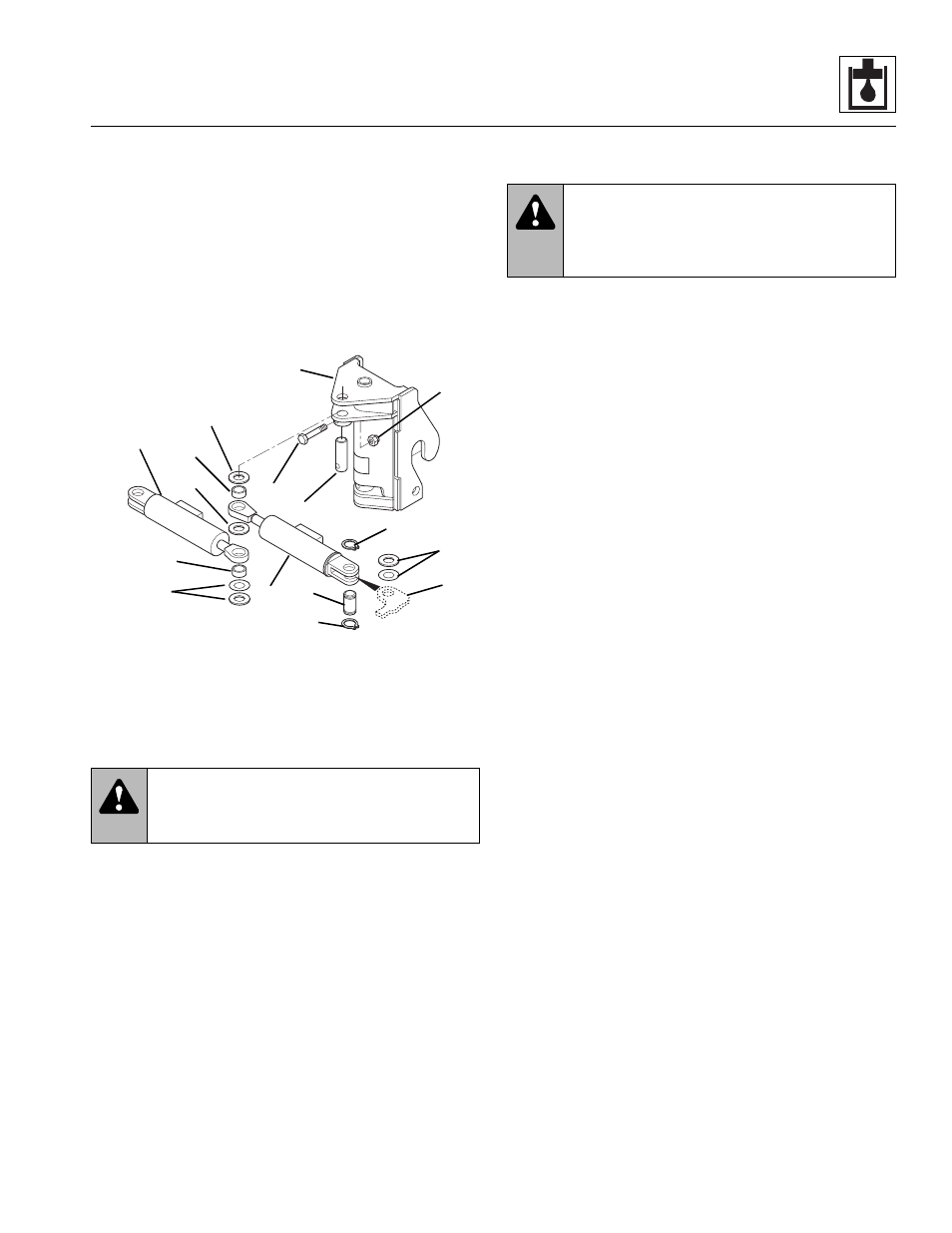

Swing Carriage Cylinder Installation

1. Install the swing carriage cylinder(s) (1) on the pivot

mount (18). Secure the rod ends to the pivot mount

using the shims (19) and bearings (20). Insert the

pin (21) and secure with the bolt (22) and nut (23).

2. Secure the tube end to the mount plates (24) using

the shims (25) and pins (26). Secure with snap

rings (27).

3. Lubricate the tube ends with multi-purpose lithium-

based grease.

4. Remove all plugs and caps from the hydraulic lines

and securely tighten the lines to the cylinder(s).

5. Start the engine.

6. Swing the carriage five times through its full range or

until the operation of the swing carriage is normal

(no jerks or spongy feel).

7. Shut the engine OFF. Check the hydraulic level and

fill as required.

g. Swing Carriage Cylinder Pressure Checking and

Circuit Bleeding

1. Attach a 5000 psi (345 bar) gauge to the main

control valve to test the swing carriage cylinder

hydraulic system circuit pressure. The unit is

equipped with test fittings from the factory. Refer to

Section 8.7, “Hydraulic System Testing.”

2. Center the swing carriage cylinders.

3. Swing the carriage fully left. Hold the joystick at full

swing left for several seconds, then swing the

carriage fully right and hold the joystick at full swing

right for several seconds.

4. Center the carriage.

5. Repeat Steps 3 thru 4 five times.

WARNING:

Escaping hydraulic fluid

under pressure can penetrate the skin, causing

death or serious injury.

MT1970

18

19

20

21

22

23

24

25

26

27

WARNING:

Avoid prolonged engine

operation in closed areas with inadequate

ventilation. Failure to properly ventilate exhaust

fumes can result in death or serious injury.