Lull 944E-42 Service Manual User Manual

Page 78

Boom

3.30

Model 644E-42/944E-42

Rev. 6/04

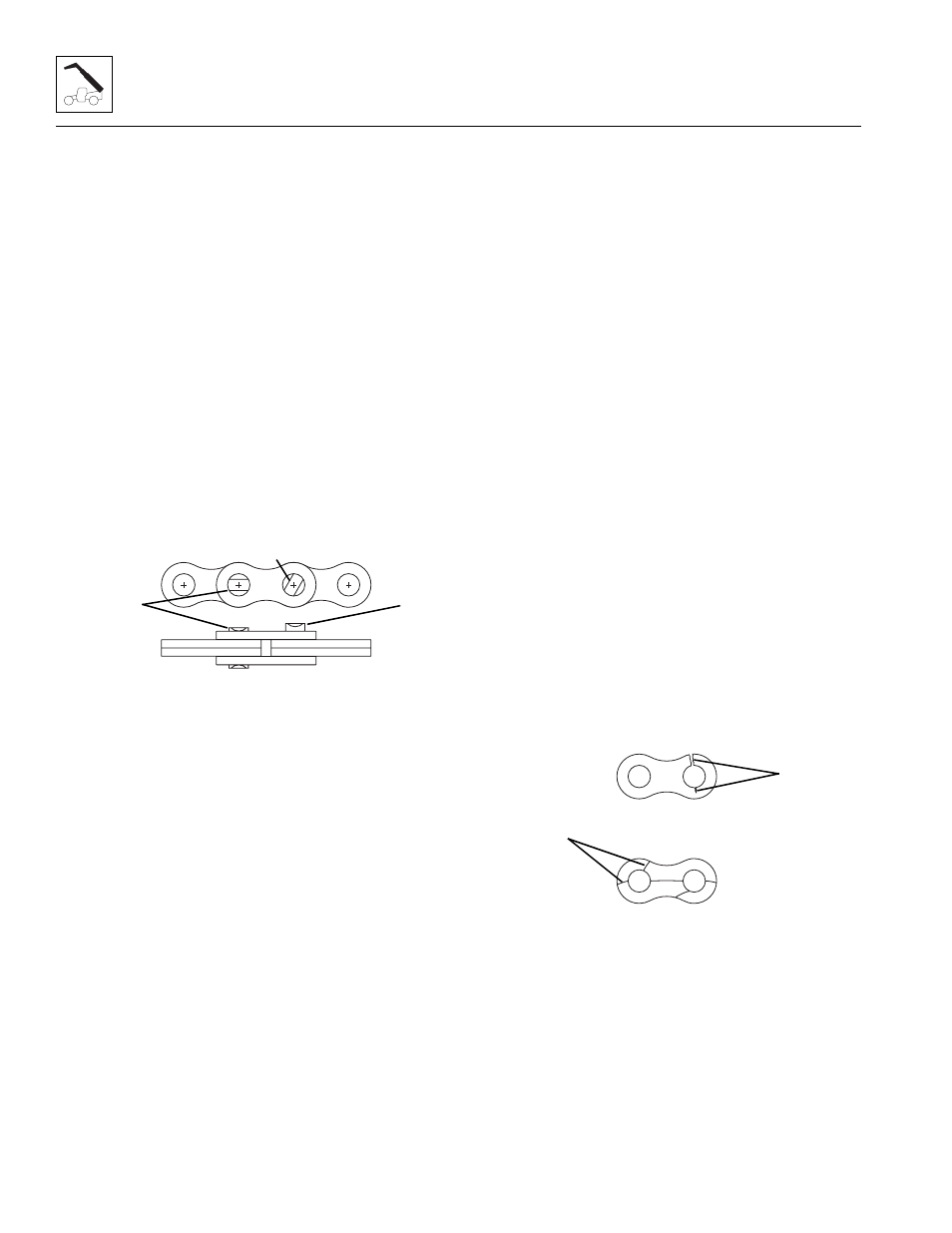

Turning or Protruding Pins

Highly loaded chain, operating with inadequate

lubrication, can generate abnormal frictional forces

between pin and link plates. When chain is allowed to

operate in this condition, a pin or series of pins, can begin

to twist out of a chain, resulting in failure.

Examine the pin head rivets to determine if the “VEE” flats

are still in correct alignment (1). Chain with rotated/

displaced heads (2) or abnormal pin protrusion (3) must

be replaced immediately. (Refer to Section 3.4.5, “Boom

Extend and Retract Chains Removal and Replacement.”)

DO NOT attempt to repair the chain by welding or driving

the pin(s) back into the chain. Once the press fit integrity

between outside plates and pins has been altered, it

cannot be restored.

Any wear pattern on the pin heads or the sides of the link

plates indicates misalignment in the system. This

condition damages the chain as well as increases

frictional loading and must be corrected.

Cracked Plates

Inspect the chains very carefully, front and back as well

as side to side, for any evidence of cracked plates. If any

one crack is discovered, the chain must be replaced in its

entirety. (Refer to Section 3.4.5, “Boom Extend and

Retract Chains Removal and Replacement.”)

• Fatigue Cracking - Fatigue cracks (4) are a result

of repeated cyclic loading beyond the chain’s

endurance limit. The size of the load and the

frequency of its occurrence are factors which

determine when fatigue failure will occur. The

loading can be continuous or intermittent

(impulse load).

• Stress Corrosion Cracking - The outside link

plates are particularly susceptible to stress

corrosion cracking (5). Like fatigue cracks, these

initiate at the point of highest stress but tend to

extend in an arc-like path between holes in the

pin plate. More than one crack can often appear

on a link plate. In addition to rusting, this

condition can be caused by exposure to an acidic

or caustic medium or atmosphere.

Stress corrosion is an environmentally assisted failure.

Two conditions must be present: corrosive agent and

static stress. In the chain, static stress is present at the

aperture due to the press fit pin. No cyclic motion is

required, and the plates can crack during idle periods.

• Corrosion Fatigue Cracking - Corrosion fatigue

cracks are very similar to fatigue cracks (4) in

appearance. They generally begin at the

aperture and grow perpendicular to the chain

pitch line. Corrosion fatigue is not the same as

stress corrosion. Corrosion fatigue is the

combined action of an aggressive environment

and cyclic stress, not a static stress alone, as in

stress corrosion.

MM2060

1

2

3

MM2080

MM2070

4

5