Pneumatic connections – Teledyne GFC-7000E - Trace CO2 Analyzer User Manual

Page 26

Model GFC7000E Instruction Manual

Getting Started

04584 Rev A1

15

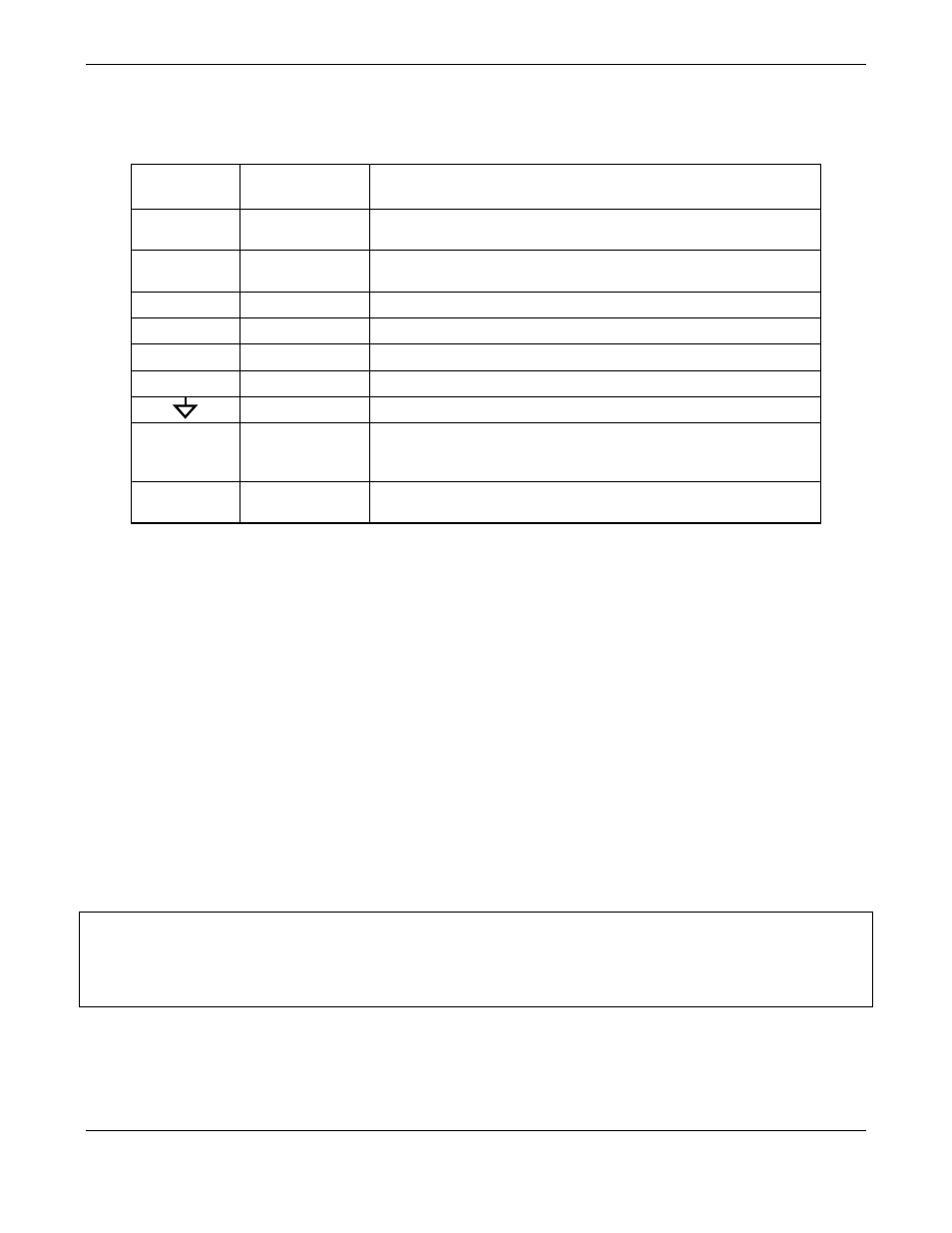

The pin assignments for the digital control inputs can be found in the table below:

Table 3-3: GFC7000E Control Input Pin Outs

Input #

Status

Definition

On Condition

A

REMOTE ZERO

CAL

The Analyzer is placed in Zero Calibration mode. The mode

field of the display will read ZERO CAL R.

B

REMOTE

SPAN CAL

The Analyzer is placed in Span Calibration mode. The mode

field of the display will read SPAN CAL R.

C

SPARE

D

SPARE

E

SPARE

F

SPARE

Digital Ground

May be connected to the ground of the datalogger/recorder.

U

Pullup supply

for inputs

Input pin for +5 VDC required to activate pins A – F. This

can be from an external source or from the “+” pin of the

instruments STATUS connector.

+

Internal +5V

Supply

Internal source of +5V which can be used to actuate control

inputs when connected to the U pin.

12. If you wish to utilize either of the analyzer’s two serial interface COMM ports, refer to Section

6.10 of this manual for instructions on their configuration and usage.

13. If your unit has a Teledyne Instruments Ethernet card (Option 63), plug one end into the 7’

CAT5 cable supplied with the option into the appropriate place on the back of the analyzer

(see Figure 5-4 in Section 5.5.3) and the other end into any nearby Ethernet access port.

3.1.2. Pneumatic Connections:

3.1.2.1. Basic Pneumatic Connections

Figures 3-3 and 3-4 illustrate the most common configurations for gas supply and exhaust lines to

the Model GFC7000E Analyzer. Figure 3-13 illustrates the internal gas flow of the instrument in

its basic configuration.

Please refer to Figure 3-2 for pneumatic connections at the rear panel and Table 3-4 for

nomenclature.

NOTE

Sample and calibration gases should only come into contact with PTFE (Teflon), FEP,

glass, stainless steel or brass. CAUTION