Delta Electronics Elevator Drive VFD-VL User Manual

Page 82

Chapter 4 Parameters|

Revision Nov. 2008, VLE1, SW V1.03 4-27

Setting 8: To increase torque and control speed precisely. (1:1000). This setting is only for

using with permanent magnet motor and others are for induction motor.

00-10

Reserved

00-11

Reserved

00-12

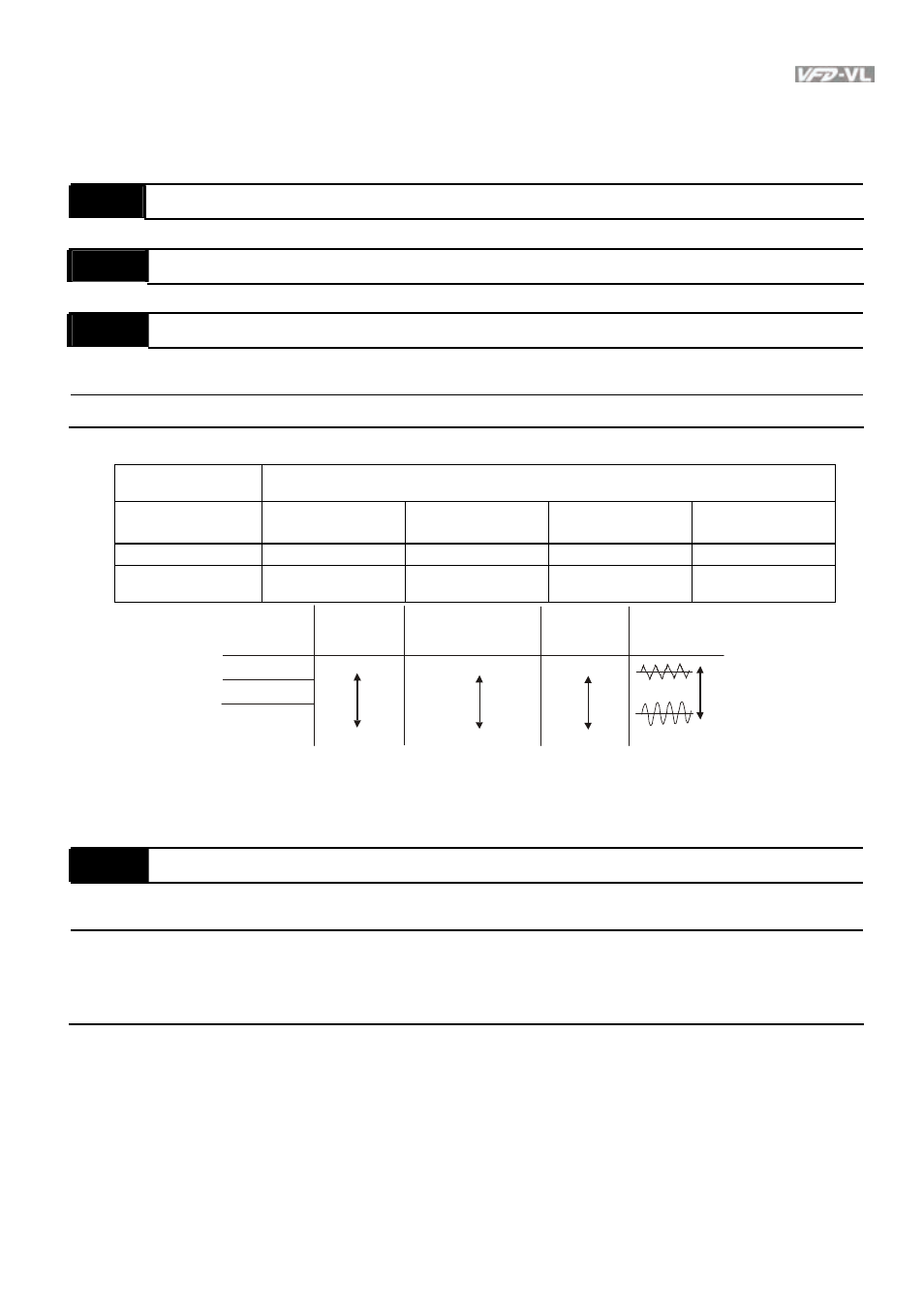

Carrier Frequency

Unit: 1

Control

mode

VF

VFPG

SVC

FOCPG TQCPG FOCPM

Factory setting: 12

Settings

2~15KHz

This parameter determinates the PWM carrier frequency of the AC motor drive.

230V/460V Series

Models

7.5-15HP

5.5-11kW

20-30HP

15-22kW

40-60 HP

30-45kW

40-100HP

30-75kW

Setting Range

2~15kHz

2~15kHz

02-09kHz 02~15kHz

Factory Setting

12kHz

9kHz 6kHz 6kHz

2kH z

8kH z

15kHz

Carrier

Frequency

Acoustic

Noise

Electromagnetic

Noise or Leakage

Current

Heat

Dissipation

Current

Wave

Significant

Minimal

Minimal

Minimal

Significant

Significant

From the table, we see that the PWM carrier frequency has a significant influence on the

electromagnetic noise, AC motor drive heat dissipation, and motor acoustic noise.

00-13

Auto Voltage Regulation (AVR) Function

Control

mode

VF

VFPG

SVC

FOCPG TQCPG FOCPM

Factory setting: 0

Settings

0

Enable

AVR

1

Disable

AVR

2

Disable AVR when deceleration stop

It is used to select the AVR mode. AVR is used to regulate the output voltage to the motor. For

example, if V/f curve is set to AC200V/50Hz and the input voltage is from 200 to 264VAC, the

output voltage won’t excess AC200V/50Hz. If the input voltage is from 180 to 200V, the output

voltage to the motor and the input voltage will be in direct proportion.

When setting Pr.00-13 to 1 during ramp to stop and used with auto accel./decel. function, the

acceleration will be smoother and faster.