Delta Electronics Elevator Drive VFD-VL User Manual

Page 199

Appendix B Accessories|

B-2

Revision Nov. 2008, VLE1, SW V1.03

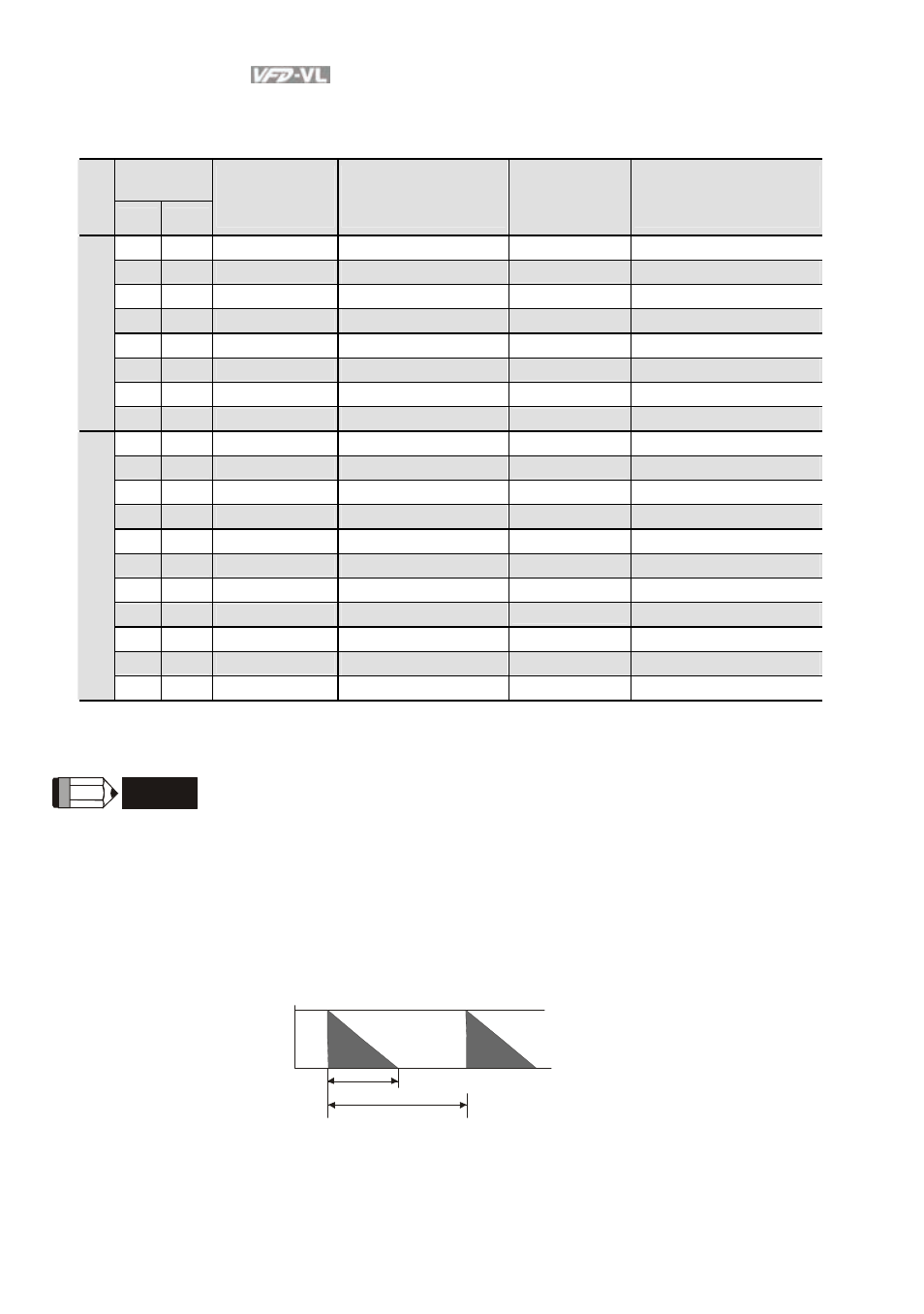

B.1 All Brake Resistors & Brake Units Used in AC Motor Drives

Applicable

Motor

Voltage

hp

kW

Full Load

Torque

Nm

Resistor value spec

for each AC Motor

Drive

Brake Torque

10%ED

Min. Equivalent

Resistor Value for each

AC Motor Drive

7.5 5.5

3.111

2400W 16Ω

125

16Ω

10

7.5

4.148

3000W 12Ω

125

12Ω

15 11

6.186

4800W 9Ω

125

9Ω

20

15

8.248

4800W 6.8Ω

125

6.8Ω

25 18.5

10.281

6000W 6Ω

125

6Ω

30

22

12.338

9600W 5Ω

125

5Ω

40 30

16.497

6000W 5Ω

125

5Ω

230V Se

ries

50

37

20.6

9600W 4Ω

125

4Ω

7.5 5.5

3.111

500W 50Ω

125

50Ω

10

7.5

4.148

1000W 40Ω

125

40Ω

15 11

6.186

1000W 33Ω

125

33Ω

20

15

8.248

1500W 25Ω

125

25Ω

25 18.5

10.281

4800W 21Ω

125

21Ω

30

22

12.338

4800W 19Ω

125

19Ω

40 30

16.497

6000W 20Ω

125

20Ω

50

37

20.6

9600W 16Ω

125

16Ω

60 45

24.745

9600W 13.6Ω

125

13.6Ω

75

55

31.11

12000W 10Ω

125

10Ω

460V Se

ries

100 75

42.7

19200W 6.8Ω

125

6.8Ω

NOTE

1.

Please select the recommended resistance value (Watt) and the duty-cycle value (ED%).

2.

Definition for Brake Usage ED%

Explanation: The definition of the brake usage ED(%) is for assurance of enough time for the

brake unit and brake resistor to dissipate away heat generated by braking. When the brake

resistor heats up, the resistance would increase with temperature, and brake torque would

decrease accordingly. Recommended cycle time is one minute.

10 0%

T0

T1

Brak e Time

C yc le Time

ED% = T1 /T0 x10 0(%)

3.

For safety consideration, install an overload relay between the brake unit and the brake resistor.

In conjunction with the magnetic contactor (MC) prior to the drive, it can perform complete

protection against abnormality. The purpose of installing the thermal overload relay is to protect