Dead band, Independent heat and cool pid, Mulitple pid sets – Watlow Series PD User Manual

Page 137: Multiple pid sets

W a t l o w S e r i e s P D

■

1 3 5

■

C h a p t e r 1 0 F e a t u r e s

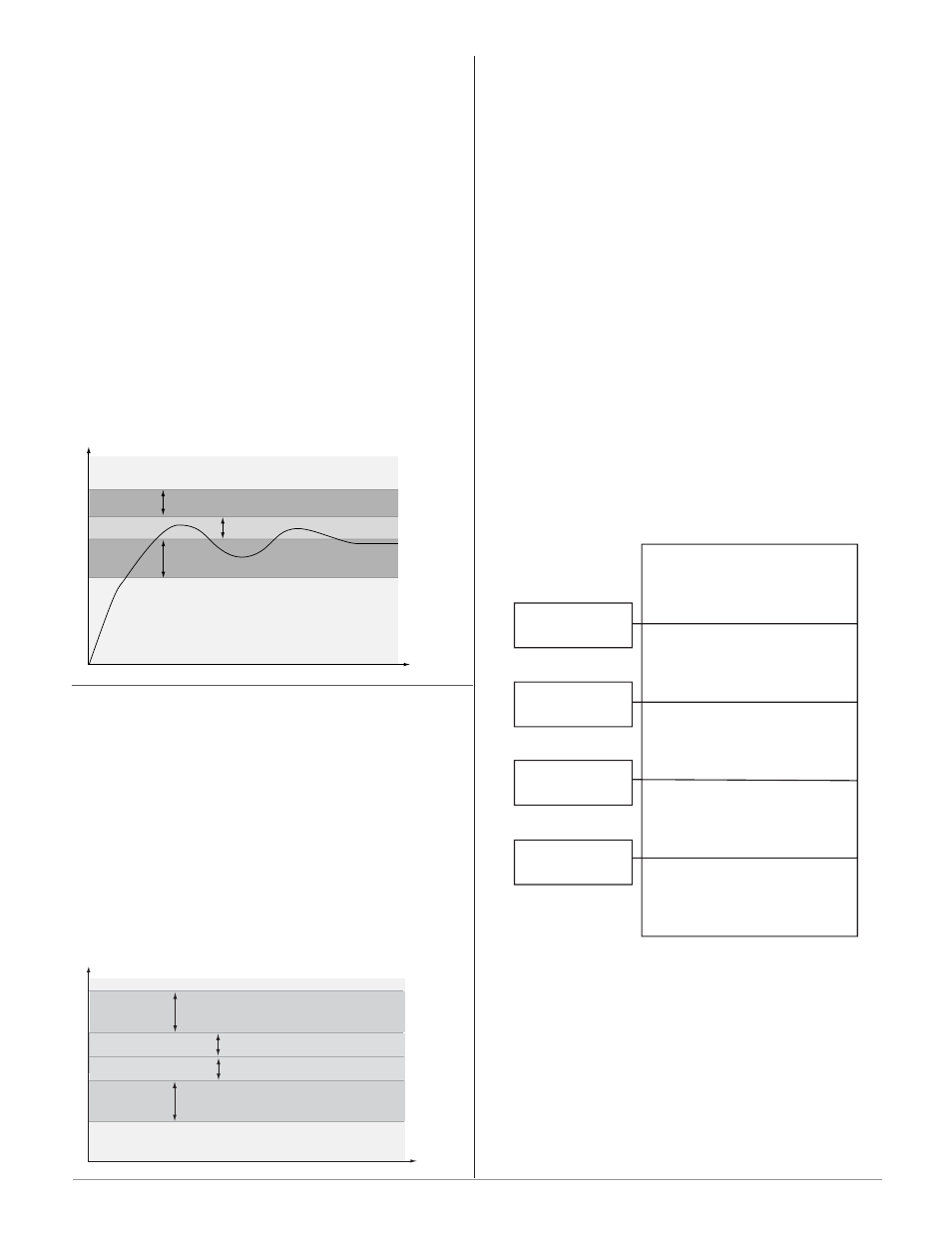

Dead Band

In heat/cool PID applications, a dead band above and

below the set point can save energy and equipment wear

by maintaining process temperature within acceptable

ranges. Shifting the effective cooling set point and heating

set point keeps the two systems from fighting each other.

Proportional action ceases when the process value is

within the dead band. Integral action continues to bring

the process temperature to the set point. When the dead

band value is zero, the heating element activates when

the temperature drops below the set point, and the cool-

ing element switches on when the temperature exceeds

the set point.

To view or change the Dead Band, go to Device Con-

figuration > Control Loops > Loop 1 or 2 > Loop

Settings > PID Parameters > PID Set #1 Dead Band

Heat (Indirect) or PID Set #1 Dead Band Cool (Di-

rect). Enter a value for Dead Band and click the Submit

button to send the new value.

Independent Heat and Cool PID

In an application with one output assigned to heating

and another assigned to cooling, each will have a separate

set of PID parameters and separate dead bands. The heat-

ing parameters take effect when the process temperature

is lower than the set point and the cooling parameters

take effect when the process temperature is higher than

the set point.

To view or change the PID Parameter values, go to De-

vice Configuration > Control Loops > Loop 1 or 2 >

Loop Settings > PID Parameters. Enter values for Pro-

portional Band, Integral, Derivative and Dead Band and

click the Submit button to send the new values.

Multiple PID Sets

The Series PD supports up to five heat/cool PID sets.

This feature is extremely valuable if the characteristics

of your thermal system vary over its operating range. All

PID sets can be auto tuned or manually tuned. The Se-

ries PD can be programmed to operate using any of the

five PID sets based on crossover points of the set point or

process value.

When the process or set point value crosses the

crossover point, the PID set designated for that region of

the operating range is used to control the percent power

being supplied to the load.

There is a -1° hysteresis for each crossover. A rising

temperature will change PID sets at the crossover value.

A falling temperature will change PID sets at the

crossover value -1°.

To view or change the the PID values or crossover set

points, go to Device Configuration > Control Loops >

Loop 1 or 2 > Loop Settings > Multiple PID Sets >

PID Set No. 1, 2, 3, 4 or 5. Enter PID values and a

crossover set point for each PID set and click the Submit

button to send the new values.

Example:

Operating Range PID Set 5

Operating Range PID Set 4

Operating Range PID Set 3

Operating Range PID Set 2

Operating Range PID Set 1

PID Crossover SP

4 to 5 @ 1250 F

PID Crossover SP

3 to 4 @ 1,000 F

PID Crossover SP

2 to 3 @ 600 F

PID Crossover SP

1 to 2 @ 300 F

Time

Te

mperature

Set Point

Heating Side Proportional Band

Heating Side Dead Band

Cooling Side Dead Band

Cooling Side Proportional Band

Time

Te

mperature

Heating Set Point

Heating Proportional Band

Cooling Dead Band

Cooling Set Point

Cooling Proportional Band