Sensor selection, Set point low limit and high limit, Voltage or current scaling – Watlow Series PD User Manual

Page 133: Process input high scale and low scale, Load current monitoring, Low process scale and high process scale

Sensor Selection

You need to configure the controller to match the in-

put device, which is normally a thermocouple, RTD or

process transmitter. When you select an input device,

the controller automatically sets the input linearization

to match the sensor. It also sets high and low limits,

which in turn limit the set point range-high and range-

low values.

To view or change the sensor type, go to Device

Configuration > Inputs > Analog Input 1 or 2 >

Analog Input Sensor Type. Select the correct sensor

type. Depending on your sensor type, you must also set

the T/C, RTD or Process Parameter values. Click the

Submit button to send the new values.

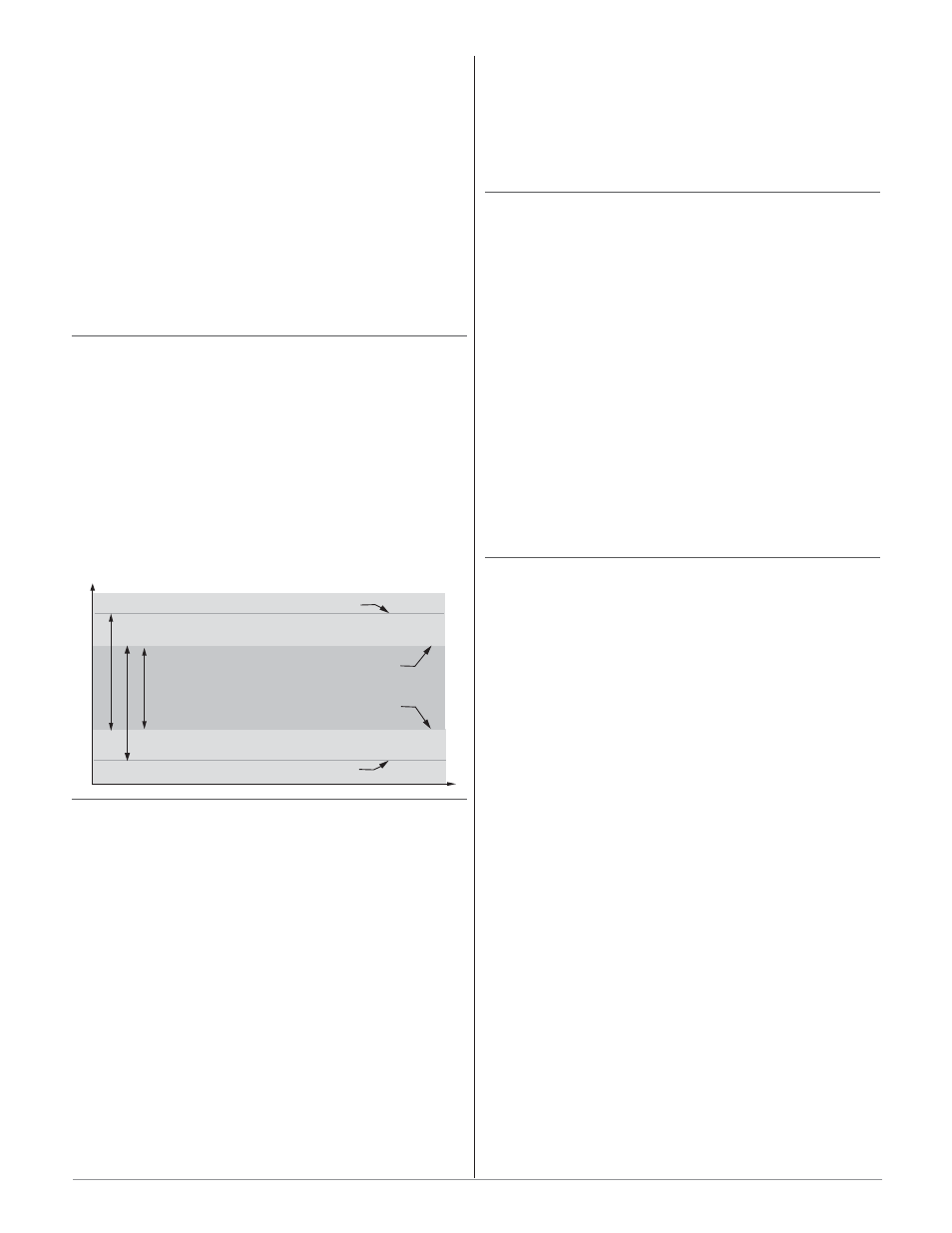

Set Point Low Limit and High Limit

The controller constrains the set point to a value be-

tween a low limit and a high limit. The set point limits

must fall between the sensor low and high range limits.

Set point values outside of the set point limits are not

valid.

To view or change the sensor type, go to Device

Configuration > Control Loops > Loop 1 or 2 >

Loop Settings > Set Point Limit Low or Set Point

Limit High. Enter a value for Limit Low and Limit

High. Click the Submit button to send the new values.

Voltage or Current Scaling

When an analog input is selected as process voltage

or process current input, you must choose the value of

voltage or current to be the low and high ends. For ex-

ample, when using a 4 to 20 mA input, the scale low

value would be 4.00 mA and the scale high value would

be 20.00 mA. Commonly used scale ranges are: 0 to 20

mA, 4 to 20 mA, 0 to 5V, 1 to 5V and 0 to 10V.

The Series PD allows you to create a scale range for

special applications other than the standard ones listed

above. Reversing of the scales from high values to low

values is permitted for analog input signals that have a

reversed action. For example, 50 psi = 4 mA and 10 psi

= 20 mA.

To view or change the input scale values, go to

Device Configuration > Inputs > Analog Input 1 or

2 > Process Parameters > Low Voltage Scale and

High Voltage Scale for voltage inputs, or Low Cur-

rent Scale and High Current Scale for current in-

puts. Enter a value for Low Scale and High Scale. Click

the Submit button to send the new values.

Low Process Scale and High Process Scale

With a process input, you must choose a value to

represent the low and high ends of the current or volt-

age range. Choosing these values allows the controller’s

display to be scaled into the actual working units of

measurement. For example, the analog input from a hu-

midity transmitter could represent 0 to 100 percent rel-

ative humidity as a process signal of 4 to 20 mA. Low

scale would be set to 0 to represent 4 mA and high scale

set to 100 to represent 20 mA. The indication on the dis-

play would then represent percent humidity and range

from 0 to 100 percent with an input of 4 to 20 mA.

To view or change the Low Process Scale or High

Process Scale values, go to Device Configuration >

Inputs > Analog Input 1 or 2 > Process Parame-

ters > Low Process Scale and High Process Scale.

Enter a value for Low Process Scale and High Process

Scale. Click the Submit button to send the new values.

Load Current Monitoring

Inputs 3 and 4 can be ordered as current trans-

former (CT) inputs. These inputs can be assigned to

monitor any control output, except process outputs, and

trigger an alarm when the load current drops below the

CT alarm set point value. This is ideal for detecting

heater loss in applications with multiple heaters. For in-

stance, if a system has five, 10 amp heaters, the CT in-

put measures 50 amps regardless of the percent output

power requested. Load current is only measured when

the time proportioned output is on.

The standard Watlow CT is designed to measure up

to 50 amps of current as it passes through the center of

the CT. See Chapter 2 for wiring information. The CT

provides an output of approximately 1 mAÅ(ac) per amp

of ac current. The CT must be purchased separately.

To enable a CT input, go to Device Configuration

> Inputs > CT Input 3 or 4 > CT Input Function,

and select CT Input.

To configure the CT input, go to Device Configura-

tion > Inputs > CT Input 3 or 4 > Current Trans-

former Parameters. Set the these parameters to

match your application requirements.

To monitor load current, go to Monitor Device >

Input Status > Input 3 or 4 Value.

To set the Current Transformer Alarm Set Point, go

to Device Configuration > Alarm 1, 2, 3, 4, 5, 6, 7 or

8 > Current Transformer Alarm Parameters >

Alarm Set Point. Enter the load current value that

will trip the current transformer alarm.

Set Point Range (must be between Range High and Range Low)

Low Limit of selected Sensor Range

High Limit of selected Sensor Range

Temperature

Set Point Limit High (between High Limit and Low Limit of Sensor)

Set Point Limit Low (between Low Limit and High Limit of Sensor)

Limit Low

Limit High

W a t l o w S e r i e s P D

■

1 3 1

■

C h a p t e r 1 0 F e a t u r e s