On-off control, Proportional control – Watlow Series PD User Manual

Page 135

To set the input error failure mode, go to Device

Configuration > Control Loops > Loop 1 or 2 >

Loop Settings > Input Failure Parameters. These

settings determine controller operation in the event of a

sensor failure. You can choose to have the controller

perform a “bumpless” transfer, switch power to output a

preset manual power level, or turn the output power off.

Bumpless transfer will allow the controller to trans-

fer to the manual mode using the last power value cal-

culated in the auto mode, if the process was stable at a

±5 percent output power level for two minutes prior to

sensor failure, and the power level is less than 75 per-

cent.

To determine the controller’s response once a valid

input signal returns to the controller, go to Device

Configuration > Control Loops > Loop 1 or 2 >

Loop Settings > Input Failure Parameters > Fail-

ure Latching. If you want any input errors to latch,

set Failure Latching to On. With this setting the con-

troller will continue to indicate an input error until the

error is manually cleared. To clear a latched error, go to

Monitor Device > Process Value > Status and click

the Acknowledge button.

If Failure Latching is set to off, the controller will

automatically clear the input error, change the Status

back to No Fault and return to reading the tempera-

ture. If the controller was in the auto mode when the in-

put error occurred, it will return to auto mode and re-

sume closed loop control. If the controller was in manu-

al mode when the error occurred, the controller will re-

main in open loop control.

To view or change the control mode of operation, go

to Monitor Device > Control Loop Status > Mode

and select Off (control loop outputs disabled), Manual

(open loop) or Auto (closed loop).

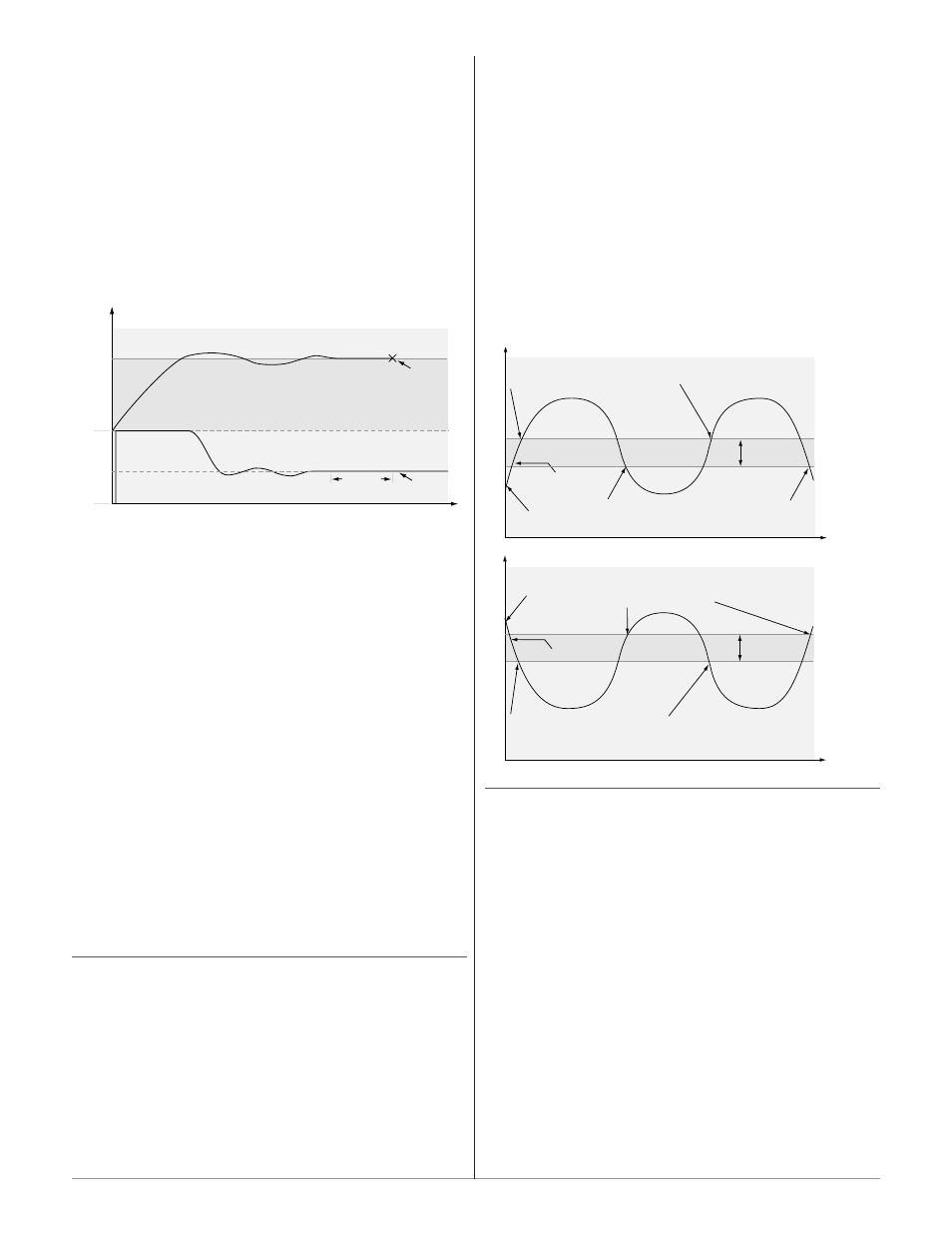

On-Off Control

On-off control switches the output either full on or

full off, depending on the input, auto set point and hys-

teresis values. The hysteresis value indicates the

amount the process value must deviate from the set

point to turn on the output. Increasing the value de-

creases the number of times the output will cycle. De-

creasing hysteresis improves controllability. With hys-

teresis set to 1, the process value would stay closer to

the auto set point, but the output would switch on and

off more frequently, and may result in the output “chat-

tering.”

To select On-off control, go to Device Configura-

tion > Control Loops > Loop 1 or 2 > Loop Settings

> Loop Heat Algorithm or Loop Cool Algorithm

and select On/Off.

To adjust the hysteresis, go to Device Configura-

tion > Control Loops > Loop 1 or 2 > Loop Settings

> On/Off Parameters > Heat (Indirect) or Cool (Di-

rect). Enter a value for hysteresis and click the Submit

button to send the new value.

NOTE: Input Error Failure Parameters have no effect in on-off control

mode. The control outputs go off.

Proportional Control

Some processes need to maintain a temperature or

process value closer to the set point than on-off control

can provide. Proportional control provides closer control

by adjusting the output when the temperature or

process value is within a proportional band. When the

value is in the band, the controller adjusts the output

based on how close the process value is to the set point.

The closer the process value is to the set point, the low-

er the output power. This is similar to backing off on

the gas pedal of a car as you approach a stop sign. It

keeps the temperature or process value from swinging

as widely as it would with simple on-off control. Howev-

er, when the system settles down, the temperature or

process value tends to “droop” short of the set point.

With proportional control the output power level

equals (set point minus process value) divided by the

proportional band value.

Set Point

Time

Te

mperature

The heating action switches off when the process

temperature rises above the set point.

The heating action

switches on at startup.

Hysteresis

Process Temperature

Hysteresis

Time

Te

mperature

The cooling action

switches

on at startup.

Process Temperature

The cooling action switches on when

the process temperature rises above

the set point plus the hysteresis.

Set Point

The heating action switches on when the process temperature

drops below the set point minus the hysteresis.

The cooling action switches off when the process

temperature drops below the set point.

Time

Temperature

40%

Sensor

Break

2 minutes

Locks in

Output

Power

0%

Set Point

Actual Temperature

Output Power

Power

100%

W a t l o w S e r i e s S D

■

1 3 3

■

C h a p t e r 1 0 F e a t u r e s