Troubleshooting general system problems – Rockwell Automation 999 IMC S Class Compact Motion Controller (Cat. No. 4100-999-122) User Manual

Page 178

7-8

Troubleshooting

Publication 999-122 - January 1997

Troubleshooting General

System Problems

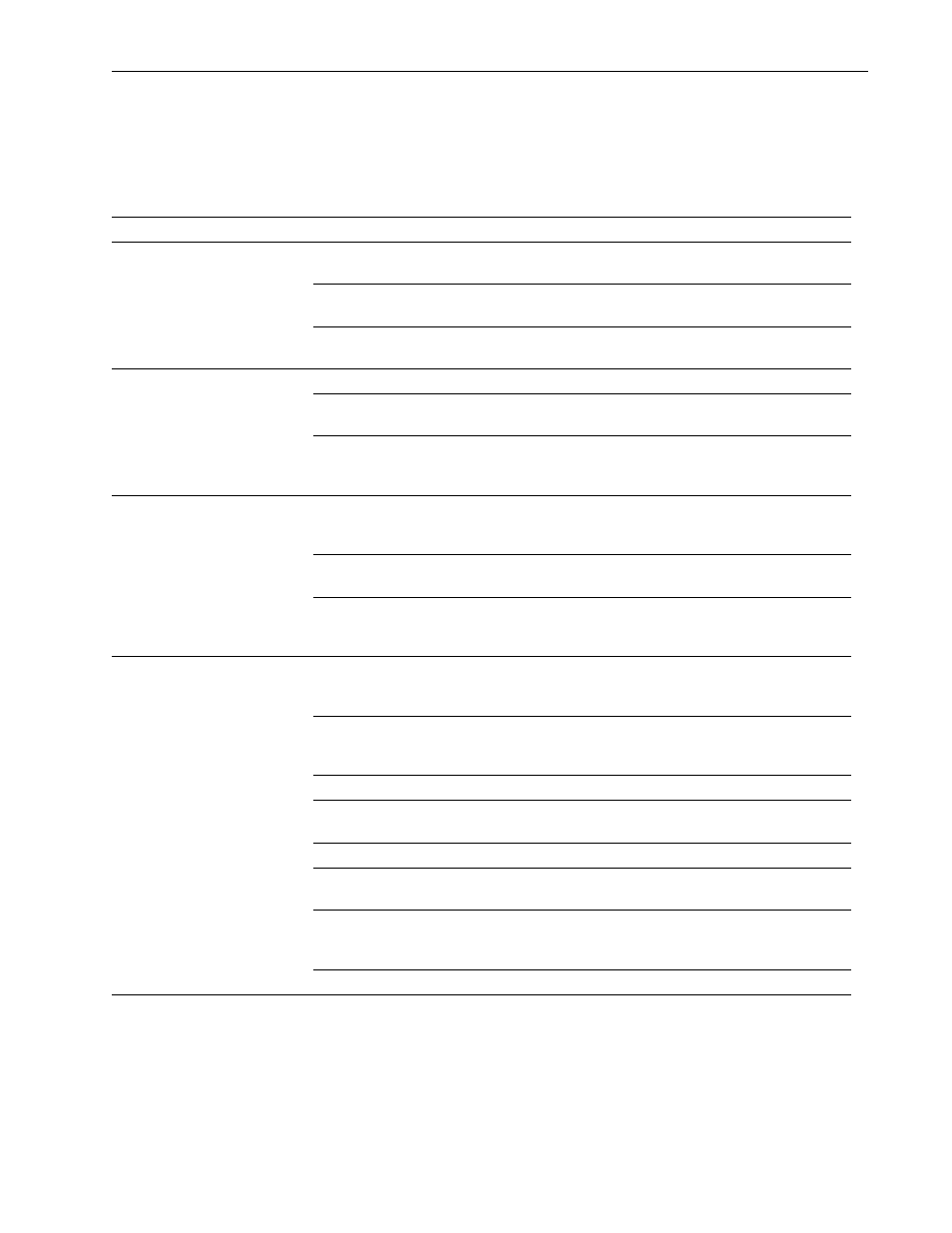

The tables that follow provide potential conditions that could occur

with your system and recommends possible resolutions to those

conditions.

Table 7.B System Troubleshooting

Condition:

Potential cause:

Possible resolution:

Axis runs uncontrollably

The velocity feedback, position feedback device, or

velocity command signal wiring is incorrect or open.

•

Check wiring.

Unintentionally in torque mode.

•

Check to see what mode was

programmed.

An internal malfunction exists.

•

Replace system or axis

module.

Axis is unstable

[Prop Gain, Intg Gain, Feed Fwd Gain] are set too high.

•

Run auto tune.

Position loop gain or position controller accel/decel rate

is improperly set.

•

Run auto tune.

Improper grounding or shielding techniques are causing

noise to be transmitted into the position feedback or

velocity command lines, causing erratic axis movement.

•

Check wiring and ground.

You cannot obtain the motor

acceleration/deceleration that

you want

The system inertia is excessive.

•

Check motor size vs.

application need.

•

Review servo system sizing.

The system friction torque is excessive.

•

Check motor size vs.

application need.

Available current is insufficient to supply the correct

accel/decel rate.

•

Check motor size vs.

application need.

•

Review servo system sizing.

Motor does not respond to a

Velocity Command

Check for possible faults.

•

Verify that the parameters are

set correctly and correct

them, as necessary.

Enable signal has not been applied or the enable wiring is

incorrect.

•

Check the controller.

•

Check the wiring.

•

Check drive control.

The motor wiring is open.

•

Check the wiring.

The motor thermal overload has tripped.

•

Check for a fault.

•

Check the wiring.

The motor has malfunctioned.

•

Repair or replace the motor.

The coupling between motor and machine has broken

(i.e., the motor moves, but the load/machine doesnít).

•

Check and correct the

mechanics.

[CW, CCW VEL Lim] parameters are set incorrectly.

•

Check and properly set the

parameter.

•

Retune.

The drive has malfunctioned.

•

Replace the drive.