Lubricants, fluids, and system capacities, Table 5.15 system capacities, Lubricants, fluids – MacDon M205 Operators Manual User Manual

Page 301

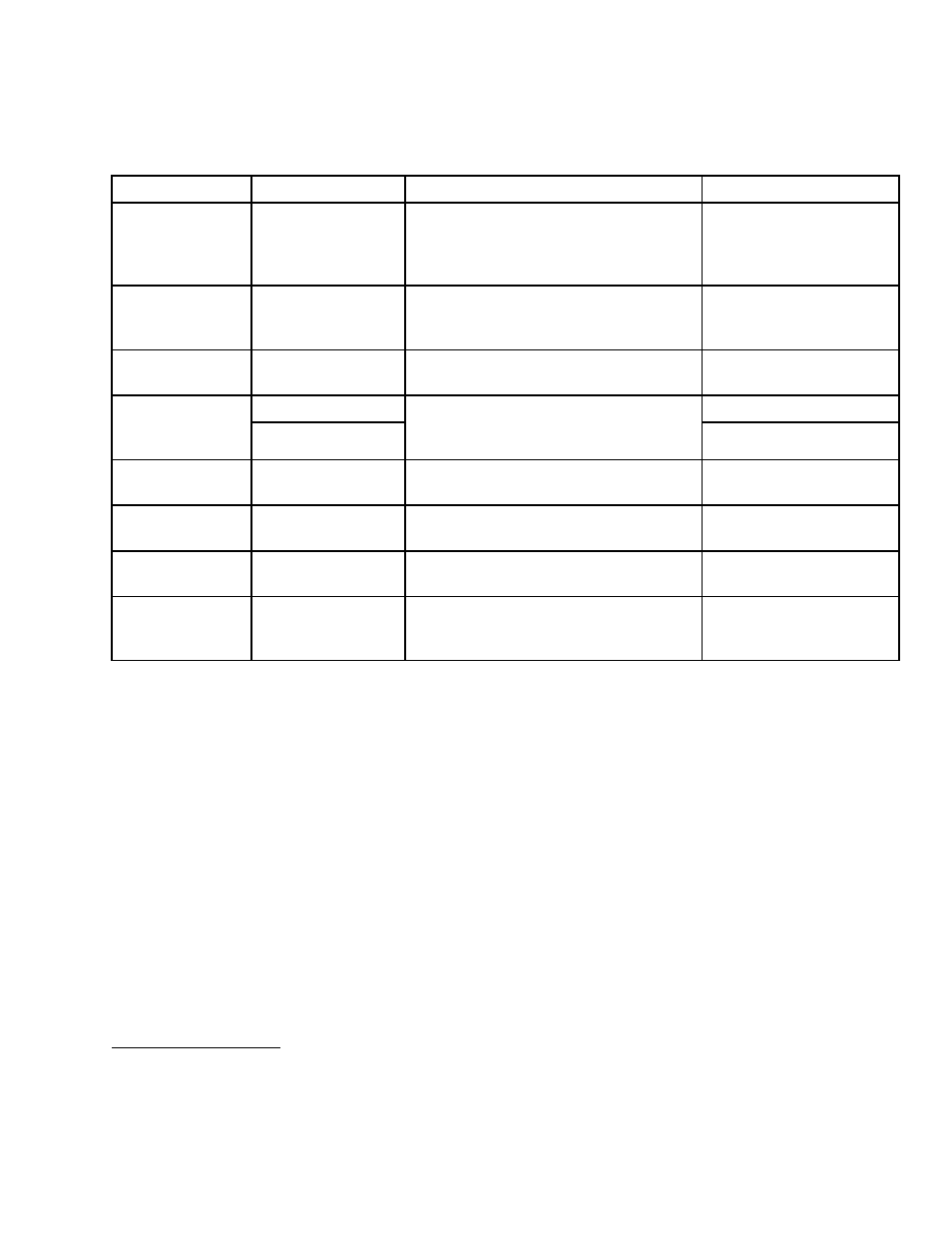

Lubricants, Fluids, and System Capacities

Table 5.15 System Capacities

Lubricant/Fluid

Location

Description

Capacity

Grease

As required unless

otherwise specified

SAE Multi-Purpose.High Temperature

Extreme Pressure (EP2) Performance

With 1% Max Molybdenum Disulphide

(NLGI Grade 2) Lithium Base

Diesel fuel

Fuel tank

Diesel Grade No.2, or Diesel Grade No.1

and 2 mix

30

; refer to

for more information

97 U.S. Gallons (378

liters)

Hydraulic oil

Hydraulic reservoir

SAE 15W-40 Compliant With SAE Specs

For API Class SJ and CH-4 Engine Oil

17.2 U.S. Gallons (66

liters)

Gear box

2.2 U.S. Quarts (2.1 liters)

Gear lubricant

Wheel drive

31

SAE 75W-90, API Service Class

GL-5.Fully Synthetic Gear Lubricant,

(SAE J2360 Preferred)

1.5 U.S. Quarts (1.4 liters)

Antifreeze

Engine cooling

system

ASTM D-4985, Ethylene Glycol with SCA

8.2 U.S. Gallons (31

liters)

32

Engine Oil

Engine oil pan

SAE 15W-40 Compliant With SAE Specs

For API Class SJ and CH-4 Engine Oil

15.0 U.S. Quarts (14.2

liters)

Air conditioning

refrigerant

Air conditioning

system

R134A

5 lb. (2.27 kg)

Air conditioning

refrigerant oil

33

Air conditioning

system total

capacity

PAG SP-15

8.1 fl. oz. (240 cc)

If Fleetguard ES Compleat

®

is unavailable, use a coolant concentrate or prediluted coolant intended for use with

heavy duty diesel engines and with a minimum of the following chemical and physical properties:

• Is formulated with a quality nitrite free additive package.

• Provides cylinder cavitation protection according to fleet study run at or above 60% load capacity.

• Protects the cooling system metals (cast iron, aluminum alloys, and copper alloys such as brass) from corrosion.

The additive package must be part of one of the following coolant mixtures:

• Ethylene glycol or propylene glycol base prediluted (40–60%) heavy duty coolant.

• Ethylene glycol or propylene glycol base heavy duty coolant concentrate in a 40–60% mixture of concentrate with

quality water.

Water quality is important to the performance of the cooling system. Distilled, deionized, or demineralized water is

recommended for mixing with ethylene glycol and propylene glycol base engine coolant concentrate.

IMPORTANT:

Do NOT use cooling system sealing additives or antifreeze that contains sealing additives. Do NOT mix ethylene

glycol and propylene glycol base coolants. Do NOT use coolants that contain nitrites.

30. Optional when operating temperature is below 32°F.(0°C).

31. SAE 85W-140 API Service Class GL-5. Extreme Pressure Gear Lubricant is used before initial change.

32. Equal parts with water, high quality, soft, de-ionized or distilled water as recommended by supplier.

33. New compressor (MD #203013) comes filled. If installing on 2014 and prior, refer to Service Bulletin 1254.

169887

285

Revision A