IAI America PSEL User Manual

Page 260

250

Part 2 Programs

B.

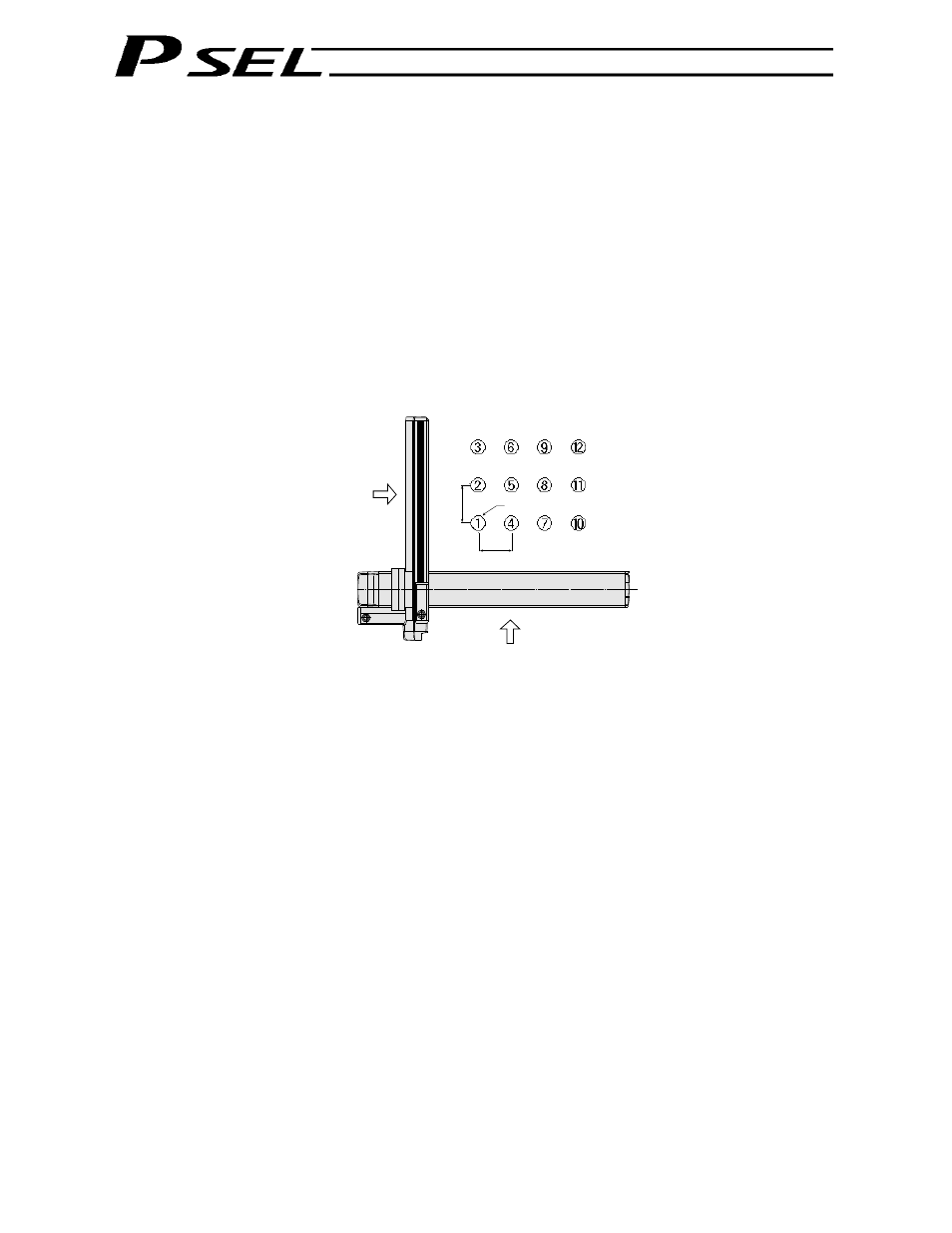

Method to set palletizing positions in parallel with the actuators

Palletizing reference point: Store the position data of the start point (palletizing position No. 1) in a

position data field and specify the applicable position number using a PAST

command, as shown below.

Palletizing pitches:

Use a PAPT command to specify the pitches in the PX-axis and PY-axis

directions.

Palletizing axes:

Use a PASE command to specify the two axes, one representing the PX-axis

direction and the other representing the PY-axis direction, to be used in

palletizing.

(An actuator axis number parallel with the preferential axis (PX-axis) and another perpendicular to the

preferential axis)

PAST

100

Teach position data No. 100 as the start point.

PAPT

45 30 The

PX-axis

direction

pitch

is 45 mm and the PY-axis direction

pitch is 30 mm.

PASE

2

1

Set the PX-axis as axis 2 and PY-axis as axis 1.

(Note) When the above palletizing axes, palletizing pitches and palletizing reference point

are used, the PX-axis and PY-axis must be parallel with the actuators and crossing

with each other.

Select either method A or B for each palletizing setting.

A

xis 2

PX-axis directi

on pitch

45

30

Teach position data No. 100.

Axis 1

PY-axis direction pitch