IAI America PSEL User Manual

Page 259

249

Part 2 Programs

A. 3-point teaching method

To set the palletizing positions by 3-point teaching, store desired positions in position data fields as

three continuous position data and then specify the first position number using a PAPS command.

This method allows you to set the PX-axis and PY-axis as three-dimensional axes not parallel with

the actuators and not crossing with each other.

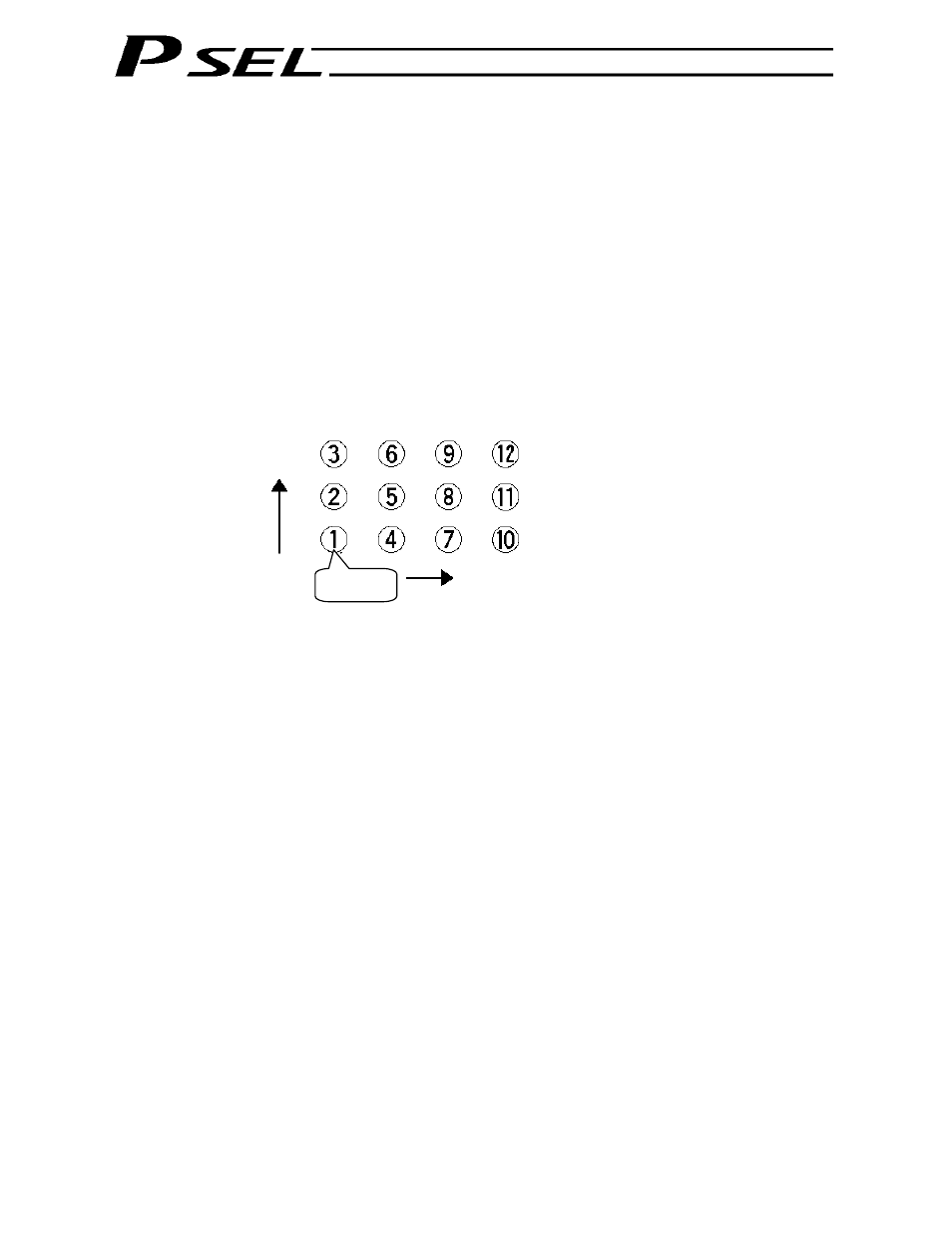

In the example shown below, position data

, and are stored in three continuous position data

fields.

When three points are taught from position No. 11

Position No. 11

[1]: Start point (First palletizing position)

Position No. 12

[3]: Palletizing position corresponding to the end point in the PX-axis direction

Position No. 13

[10]: Palletizing position corresponding to the end point in the PY-axis direction

The encircled numbers indicate palletizing position numbers (palletizing order).

Use a PAPS command to specify the position number corresponding to the start point.

Fig. 1

PAPS 11

The pitches are calculated automatically from the count set for each axis.

When setting data for 3-point teaching, specify position data for two axes.

Preferential

axis

(PX-axis)

Start point

(PY-axis)