95 part 2 programs – IAI America PSEL User Manual

Page 105

95

Part 2 Programs

Operation type in the output field

CC: Command was executed successfully, ZR: Operation result is zero,

PE: Operation is complete, CP: Command part has passed, TU: Time up

EQ: Operand 1 = Operand 2, NE: Operand 1

Operand 2,

GT: Operand 1 > Operand 2, GE: Operand 1

Operand 2,

LT: Operand 1 < Operand 2, LE: Operand 1

Operand 2

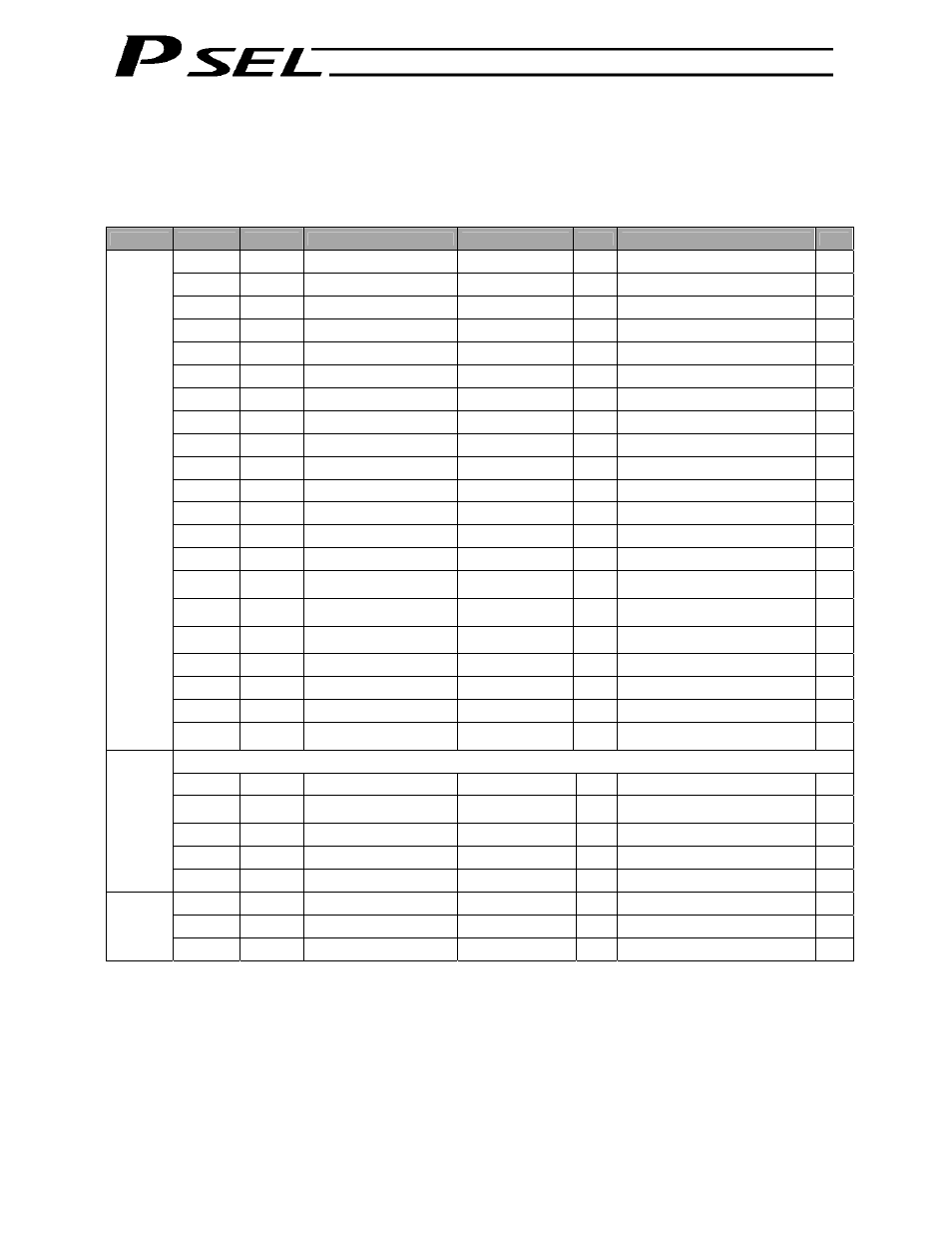

Category

Condition Command

Operand 1

Operand 2

Output

Function

Page

Optional

ARCH

Position number

Position number

PE

Arch motion

222

Optional

ACHZ

Axis number

Prohibited

CP

Declare arch-motion Z-axis

224

Optional

ATRG

Position number

Position number

CP

Set arch triggers

225

Optional

OFAZ

Offset amount

Prohibited

CP

Set arch-motion Z-axis offset

226

Optional

BGPA

Palletizing number

Prohibited

CP

Declare start of palletizing setting

227

Prohibited

EDPA

Prohibited

Prohibited

CP

Declare end of palletizing setting

227

Optional PAPI

Count

Count

CP

Set

palletizing

counts

228

Optional

PAPN

Pattern number

Prohibited

CP

Set palletizing pattern

228

Optional

PASE

Axis number

Axis number

CP

Set palletizing axes

229

Optional PAPT

Pitch

Pitch

CP

Set

palletizing

pitches

229

Optional

PAST

(Position number)

Prohibited

CP

Set palletizing reference point

230

Optional

PAPS

Position number

Prohibited

CP

Set 3 palletizing points for teaching

231

Optional

PSLI

Offset amount

(Count)

CP

Set zigzag

233

Optional

PTNG

Palletizing number

Variable number

CP

Get palletizing position number

234

Optional PINC

Palletizing

number

Prohibited

CC

Increment palletizing position

number by 1

234

Optional PDEC

Palletizing

number

Prohibited

CC

Decrement palletizing position

number by 1

235

Optional PSET

Palletizing

number

Data

CC

Set palletizing position number

directly

235

Optional

PARG

Palletizing number

Axis number

CP

Get palletizing angle

236

Optional

PAPG

Palletizing number

Position number

CP

Get palletizing calculation data

236

Optional

PMVP

Palletizing number

(Position number)

PE

Move to palletizing points via PTP

237

Palletizing-

related

Optional PMVL

Palletizing

number

(Position

number) PE

Move to palletizing points via

interpolation

238

Extension conditions LD (LOAD), A (AND), O (OR), AB (AND BLOCK) and OB (OR BLOCK) are supported.

Optional

CHPR

0 or 1

Prohibited

CP

Change task level

239

Prohibited

TPCD

0 or 1

Prohibited

CP

Specify processing to be performed

when input condition is not specified

239

Prohibited TSLP Time

Prohibited

CP

Task

sleep

240

Optional

OUTR

Output, flag number

Prohibited

CP

Output relay for ladder

Reference

257

Building of

pseudo-

ladder task

Optional

TIMR

Local flag number

Timer setting

CP

Timer relay for ladder

Reference

257

Optional

ECMD

1

Axis number

CC

Get motor current value

241

Optional

ECMD

5

Axis number

CC

Get axis operation status

242

Extended

command

Optional

ECMD

20

Variable number

CC

Get parameter value

243