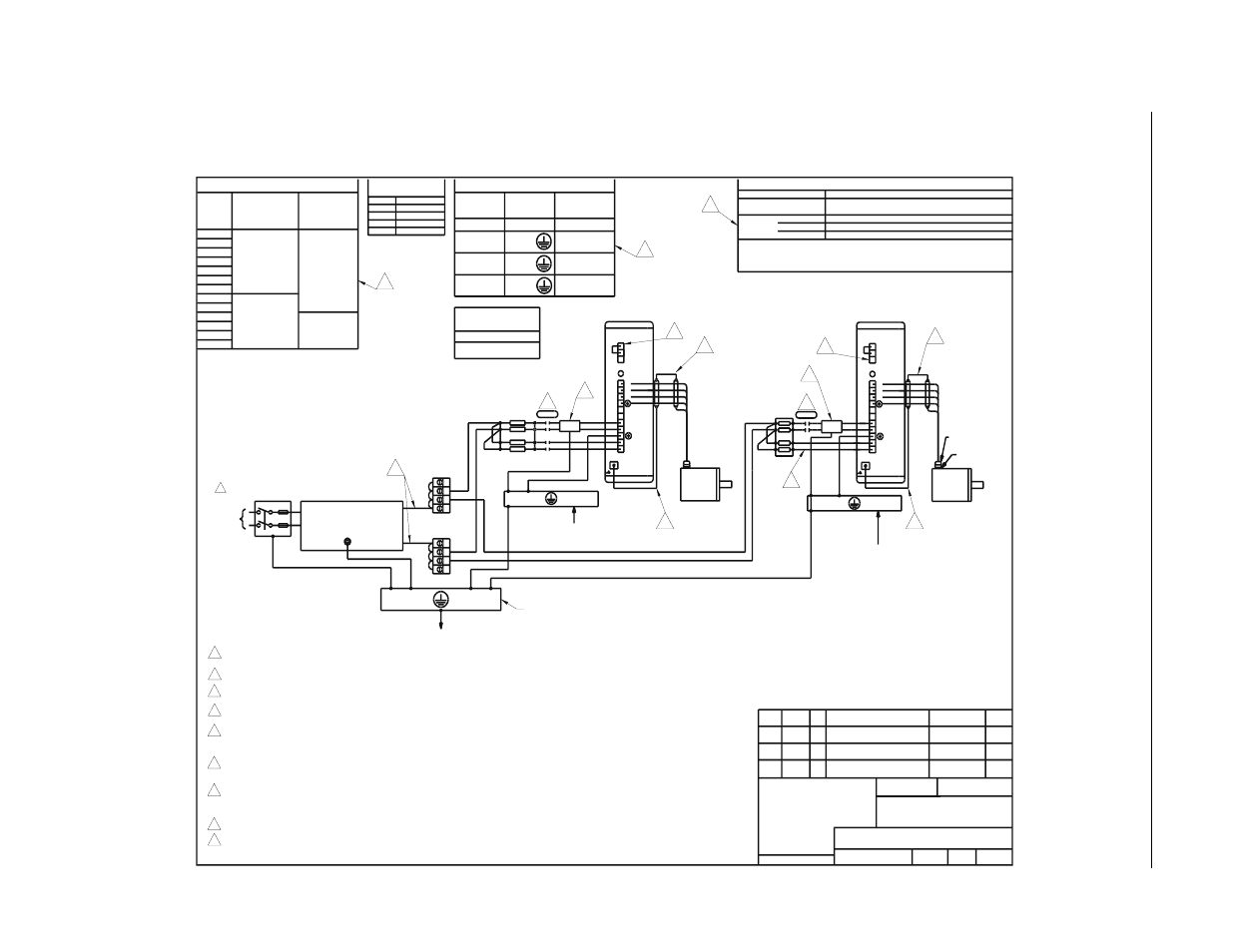

Power wiring diagram, Figure 5.4, Figure 5.4 power wiring diagrams (sheet 1 of 3) – Rockwell Automation 1398-DDM-xxx USE MNL/ULTRA 200 DIG.SERVO.DR User Manual

Page 61: Released, Input power wires

In

sta

lla

tio

n

5

-11

P

u

b

licat

io

n

1

398

-5

.0 –

Oc

to

b

e

r 1

9

9

8

Figure 5.4

Power Wiring Diagrams

(sheet 1 of 3)

Intro

BY

ECO

REV

DO NOT SCALE DRAWING

DIMENSIONS ARE IN INCHES

BREAK ALL EDGES .02 MAX

FILLETS AND ROUNDS .02 R MAX

TOLERANCE ON:

ANGLES ±1ANGLES °

FRACTIONS: ±1/64"

DECIMALS .XX ±.01

.XXX ±.005

CHKR

DATE

REVISION DESCRIPTION

PART NO.

DWG SIZE

SCALE

SHEET

DRAWN BY

DATE

DESIGN ENGR

DATE

DESIGN POST

C

of

9

3

A

21732

JM

RELEASED

1-22-96

BB

1-22-96

MC

1-9-96

JM

DIAG., POWER WIRING CONNECTIONS,

DDM-010, -020, -030

9101-1431

1:1

1

1

WIRE SIZES ARE MINIMUM RECOMMENDED VALUES. THE REQUIREMENTS OF LOCAL REGULATIONS SHOULD BE OBSERVED.

TERMINATE THE MOTOR POWER CABLE SHIELD BY CLAMPING IT TO THE DRIVE WITH THE BRACKET PROVIDED. THIS BRACKET CAN BE USED FOR STRAIN RELIEF IF

AC LINE FILTER AND SHIELDED MOTOR CABLE ARE TO BE USED FOR IMPROVING THE DRIVE MODULES ELECTROMAGNETIC COMPATABILITY, AND ARE REQUIRED

TO MEET THE EUROPEAN ELECTROMAGNETIC COMPATABILITY DIRECTIVE. CAUTION: AC LINE FILTERS HAVE LARGE LEAKAGE CURRENTS AND REQUIRE DISCHARGE

NON-SHIELDED CABLES ARE USED. SNUG BRACKET SCREWS, DO NOT OVERTIGHTEN. NEVER TORQUE OVERR 10 LB-IN.

TIME UPON POWER REMOVAL. THE AUX INPUT HAS AN INTERNAL FILTER. WIRING BETWEEN THE DRIVE MODULE AND FILTER SHOULD BE KEPT AS SHORT AS

A SUPPLY DISCONNECTING DEVICE IS REQUIRED FOR MAINTAINANCE & SAFETY. LOCAL REGULATIONS SHOULD BE OBSERVED. IF A GROUNDED NEUTRAL IS USED

MAY BE USED TO KEEP LOGIC SECTION OF DRIVE MODULE SUPPLIES POWERED AFTER MAIN MOTOR SUPPLY IS TURNED OFF AT L1, L2/N TERMINALS (EXAMPLE:

JUMPER INSTALLED AT FACTORY FOR INTERNAL SHUNT. SEE DRAWING 9101-1328 FOR TERMINAL WIRING OF EXTERNAL SHUNT OPTION TERMINALS.

TO RETAIN DIAGNOSTIC STATUS OF DRIVE MODULE AFTER L1, L2/N POWER DOWN). SEPERATE SUPPLY PHASES MAY BE USED WHEN VOLTAGE BETWEEN ANY

TWO TERMINALS DOES NOT EXCEED 265 VAC RMS.

POSSIBLE. THE COMMON GROUND BUS BAR SHOULD BE AS CLOSE TO THE DRIVE AS POSSIBLE.

TRANSFORMER

CHASSIS

ISOLATION OR AUTO TRANSFORMER

(OPTIONAL, NOT REQUIRED WHEN

DESIRED INPUT VOLTAGE IS

AVAILABLE DIRECTLY FROM THE

LINE)

SINGLE

PHASE

AC LINE

50/60 Hz

FUSED DISCONNECT

OR CIRCUIT BREAKER

NOTES

INSTEAD OF L2 OR L2/AUX, ONLY L1 MAY BE SWITCHED OR FUSED.

L1

L2/N

MACHINE COMMON

GROUNDING BUS BAR

8.

MULTIPLE DRIVE MODULES MAY BE POWERED FROM ONE TRANSFORMER OR OTHER AC SUPPLY SOURCE.

12 AWG/3.0mm

H/S-4050

F-4050

H/S-4075

F-4075

TORQUE ALL TERMINALS

TO 11 LB-IN.

TERMINAL STRIP

ACCEPTABLE WIRE RANGE

(GAUGE/mm )

22-10 AWG/0.5-6mm

DIGITAL DRIVE

MODULE

AC LINE

FILTER

TO PROTECTIVE

EARTH TERMINAL

TERM

BLOCK

H/S-SERIES

LD-SERIES

F-SERIES

W-SERIES

MOTORS

DC BUS

TB2

TB1

FUSE

BLOCK

L2/N AUX

L1 AUX

L2/N

L1

DC-

DC+

R

S

T

XCON

(75°C COPPER MIN)

H/S-3016

LD-2003

H/S-3007

MOTOR POWER WIRES R,S,T,GND

MINIMUM

RECOMMENDED

POWER WIRE

(GAUGE/mm²)

MOTOR

16 AWG/1.5mm

LD-4012

H/S-2005

LD-3009

LD-4030

H/S-4030

F-4030

MOTOR POWER

MATING CONNECTOR

16 AWG/1.5mm

14 AWG/2.5mm

CONTACT SIZE

(GAUGE/mm )

14 AWG/2.5mm

MOTOR POWER

CONNECTOR

DRIVE

ALL

DDM-010

DDM-020

L1,L2/N,

L1,L2/N,

L1,L2/N,

DDM-030

DRIVE ENABLE INPUT MUST BE OPENED WHEN MAIN POWER IS REMOVED AND AUXILIARY POWER IS PRESENT, OR A DRIVE FAULT WILL OCCUR.

DO NOT DAISY CHAIN DRIVE MODULE POWER CONNECTIONS. MAKE SEPARATE CONNECTIONS DIRECTLY TO THE AC SUPPLY.

DRIVE RATED 100-240 VAC RMS, SINGLE PHASE INPUT VOLTAGE (230 VAC STANDARD).

6.

CURRENT RATINGS ARE INDEPENDENT OF THE INPUT VOLTAGE. REDUCED VOLTAGE WILL RESULT IN A REDUCTION IN SPEED, BUT NOT TORQUE.

TERMINAL(S)

L1 AUX,

L2/N AUX

RECOMMENDED

POWER WIRE

(GAUGE/mm )

(75°C COPPER MIN.)

16 AWG/1.5mm

10 AWG/6mm

12 AWG/3.0mm

INPUT POWER WIRES

COMMON GROUNDING

POINT FOR AMPLIFIER

SYSTEM (ONE PER AXIS)

AC AUXILIARY POWER

INPUT (OPTIONAL)

DIGITAL DRIVE MODULE INPUT CURRENT REQUIREMENTS

NOTE: POWER INITIALIZATION REQUIRES A SHORT PERIOD OF INRUSH CURRENT

OF 50A FOR THE MAIN INPUT AND 95A FOR THE AUXILIARY INPUT.

DUAL ELEMENT TIME DELAY (SLOW BLOW) FUSES ARE RECOMMENDED.

FUSE SIZES MUST BE SELECTED ACCORDING TO LOCAL REGULATIONS.

L1,L2/N,

DRIVE TERMINALS

L1 AUX, L2/N AUX

DDM-010

DDM-020

DDM-030

1.0 Amps AC at 115 Volts AC

0.5 Amps AC at 230 Volts AC

28.0 Amps AC at 100-240 Volts AC

19.0 Amps AC at 100-240 Volts AC

10.0 Amps AC at 100-240 Volts AC

CURRENT REQUIREMENT, MAXIMUM (AMPS AC RMS)

COMMON GROUNDING

POINT FOR AMPLIFIER

SYSTEM (ONE PER AXIS)

FUSE

BLOCK

AC LINE

FILTER

TB1

XCON

MOTOR POWER

CONNECTOR MATING

CONNECTOR

MOTOR POWER

DIGITAL DRIVE

MODULE

DC BUS

TB2

L2/N AUX

L1 AUX

L2/N

L1

DC-

DC+

R

S

T

H/S-SERIES

LD-SERIES

F-SERIES

W-SERIES

MOTORS

A

B

C

D

PIN

SIGNAL

R

S

T

MOTOR CASE

UNLESS OTHERWISE SPECIFIED

21782 GW

B

CHANGE NOTE 11

2-21-96

RB

22455

BK

C

CHANGE NOTE 1

_

_

1

2

3

4

5

7

9

10

11

10

2

2

2

2

10

4

2

2

2

5

7

9

11

1

7

3

9

9

9

1398-DDM-010

or

1398-DDM-

010X,

1398-DDM-020

or

1398-DDM-

020X,

1398-DDM-030

or

1398-DDM-

030X

NOTE:

Allen-Bradley supports

motors of series F, H, N, Y