Motor phasing, Back-emf and hall signals, Creating custom motor files d - 3 – Rockwell Automation 1398-DDM-xxx USE MNL/ULTRA 200 DIG.SERVO.DR User Manual

Page 267: Figure d.1 allen-bradley motor naming convention, Motor part number

Publication 1398-5.0 – October 1998

Creating Custom Motor Files

D-3

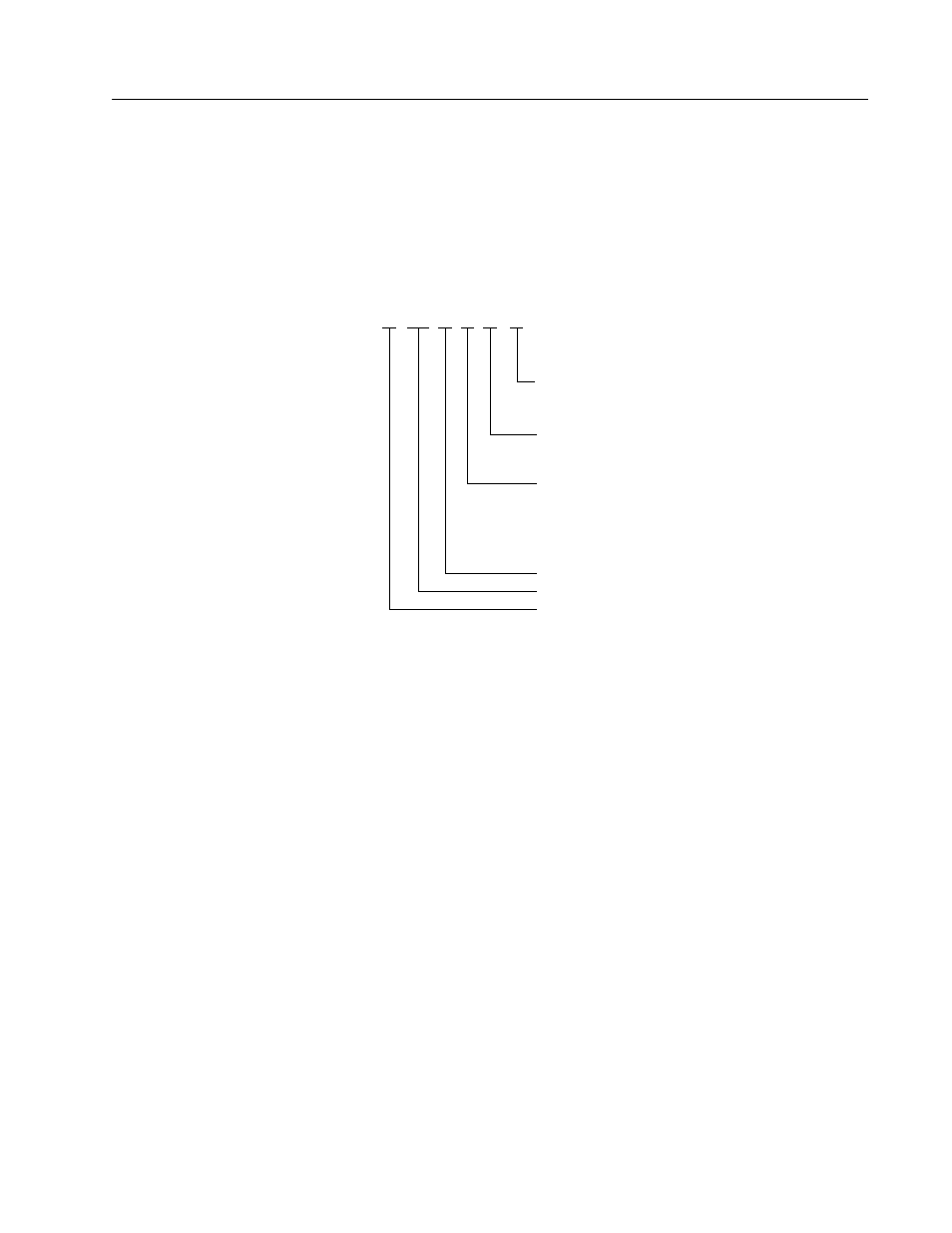

The text string translates the table ID into a real motor model number

for display. For example, the user can select the text string “H-4030-P-

H” rather than entering the table ID #23. Figure D.1 defines the text

string format of Allen-Bradley motors.

Motor Phasing

The phasing of the back-EMF and Hall feedback signals must be

verified before a custom motor file can be created. Allen-Bradley

motors use back-EMF and Hall feedback signals phased as shown in

Figure D.2. Motors not manufactured by Allen-Bradley require the

back-EMF and Hall feedback signals be phased to match those of

Allen-Bradley motors. Often this requires swapping of the R- and T-

phase control signals with each other, as well as swapping the Hall A,

Hall B, and Hall C signals with each other.

Back-EMF and Hall Signals

Figure D.2(a) shows the required phasing of the line-to-line back-

EMF signals and Figure D.2(b) shows the proper phasing of the Hall

feedback signals, when the motor is rotating clockwise (CW) as seen

looking at the motor shaft from the load.

The relationship of the Hall signals to the back-EMF signals is not

important at this stage. However, the sequencing of the back-EMF

signals must conform to Figure D.2(a), and the sequencing of the Hall

feedback signals must conform to Figure D.2(b).

Figure D.1

Allen-Bradley Motor Naming Convention

Intro

Motor Part Number

H - 4030 - P - H - 00 - AA

MOTOR WINDING K DESIGNATOR

E

SERIES DESIGNATOR

E = COMMERCIAL

F = MEDIUM INERTIA

H = LOW INERTIA

I = INDUCTION

LD = LIGHT INDUSTRIAL

N = NEMA STYLE FRAME

W = WASHDOWN

Y = LIGHT INDUSTRIAL

FRAME SIZE

FACTORY DESIGNATED SPECIAL OPTIONS

00

01

02

=

=

=

STANDARD

90 VDC BRAKE

24 VDC BRAKE

OPTICAL ENCODER LINECOUNT

F

H

J

K

L

M

N

=

=

=

=

=

=

=

1000

2000 (STANDARD)

2500

5000

500

3000

1000

FACTORY DESIGNATED SPECIAL OPTIONS

AA

AF

AG

AN

=

=

=

=

STANDARD

FLYING LEADS

IEC DIMENSIONS

NEMA 56C

FACTORY DESIGNATED SPECIAL OPTIONS

AA

= STANDARD

AF

= FLYING LEADS

AG

= IEC DIMENSIONS

AN

= NEMA 56C

FACTORY DESIGNATED SPECIAL OPTIONS

00

= STANDARD

01

= 90 VDC BRAKE

02

= 24 VDC BRAKE

OPTICAL ENCODER LINECOUNT

F

= 1000

H

= 2000 (STANDARD)

J

= 2500

K

= 5000

L

=

500

M

= 3000

N

= 1000

MOTOR WINDING K

E

DESIGNATOR

FRAME SIZE

SERIES DESIGNATOR

E

= COMMERCIAL

F

= MEDIUM INERTIA

H

= LOW INERTIA

I

= INDUCTION

N

= NEMA STYLE FRAME

W

= WASHDOWN

Y

= LIGHT INDUSTRIAL