Table 1.q tb2 - row b (bottom) wiring examples – Rockwell Automation 20D PowerFlex 700S Drive Ph I Control, Frames 1...11 User Manual

Page 45

Installation/Wiring

1-31

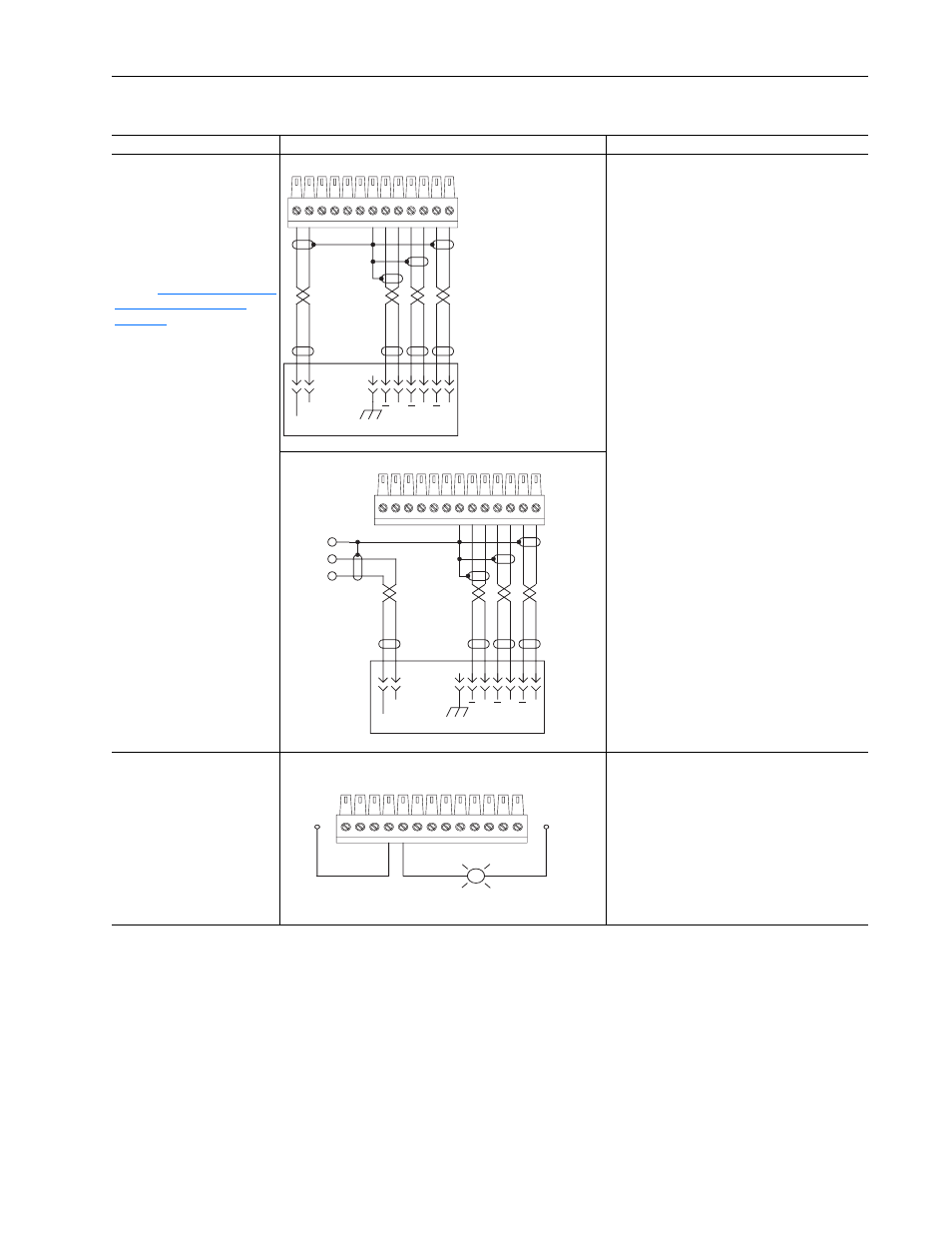

Table 1.Q TB2 - Row B (Bottom) Wiring Examples

Input/Output

Connection Example

Required Parameter Changes

Secondary Encoder Interface

- Supports 12V DC differential

encoders with internal power

supply.

5V DC differential encoders

require external power supply

and special jumper settings.

Refer to

Configuration Settings on

page 1-32

for external power

supply and jumper settings.

For 5V DC differential encoders

with internal power supply, set

Jumper J6 to positions T2 and

T3.

Secondary Encoder - using internal power supply

• Set the value of Parameter 222 [Motor Fdbk

Sel] to a value of 1 - Encoder 1, so the drive will

use this encoder as the primary motor speed

feedback device

• Set the value of Parameter 242 [Encoder1 PPR]

to match the encoder’s resolution

Secondary Encoder - using external power supply

Auxiliary Output - Relay

contact output

Auxiliary Output, Used to Indicate Running

• Link Parameter 155 [Logic Status], the source,

to Parameter 841 [Relay Out Data], the sink

• Set Parameter 842 [Relay Out Bit] to a value of

one, so that Parameter 155 [Logic Status] / bit 1

“Running” will control the output.

13

12

11

10

9

8

7

2

1

Power

Common

(Return)

A

A

B

B

Z

Z

Case Ground

13

12

11

10

9

8

7

Power

Common

(Return)

A

A

B

B

Z

Z

Case Ground

Shield

Power

Common

(Return)

4

5

Running

EXTERNAL 24V

POWER SUPPLY

EXTERNAL

24V DC

COMMON

(RETURN)