Precharge board led indications, Precharge board led indications -3, To correct – Rockwell Automation 20D PowerFlex 700S Drive Ph I Control, Frames 1...11 User Manual

Page 157: Table 4.b

Troubleshooting

4-3

Precharge Board LED Indications

Precharge Board LED indicators are found on Frame 5 & 6 drives. The

LEDs are located above the “Line Type” jumper shown in

.

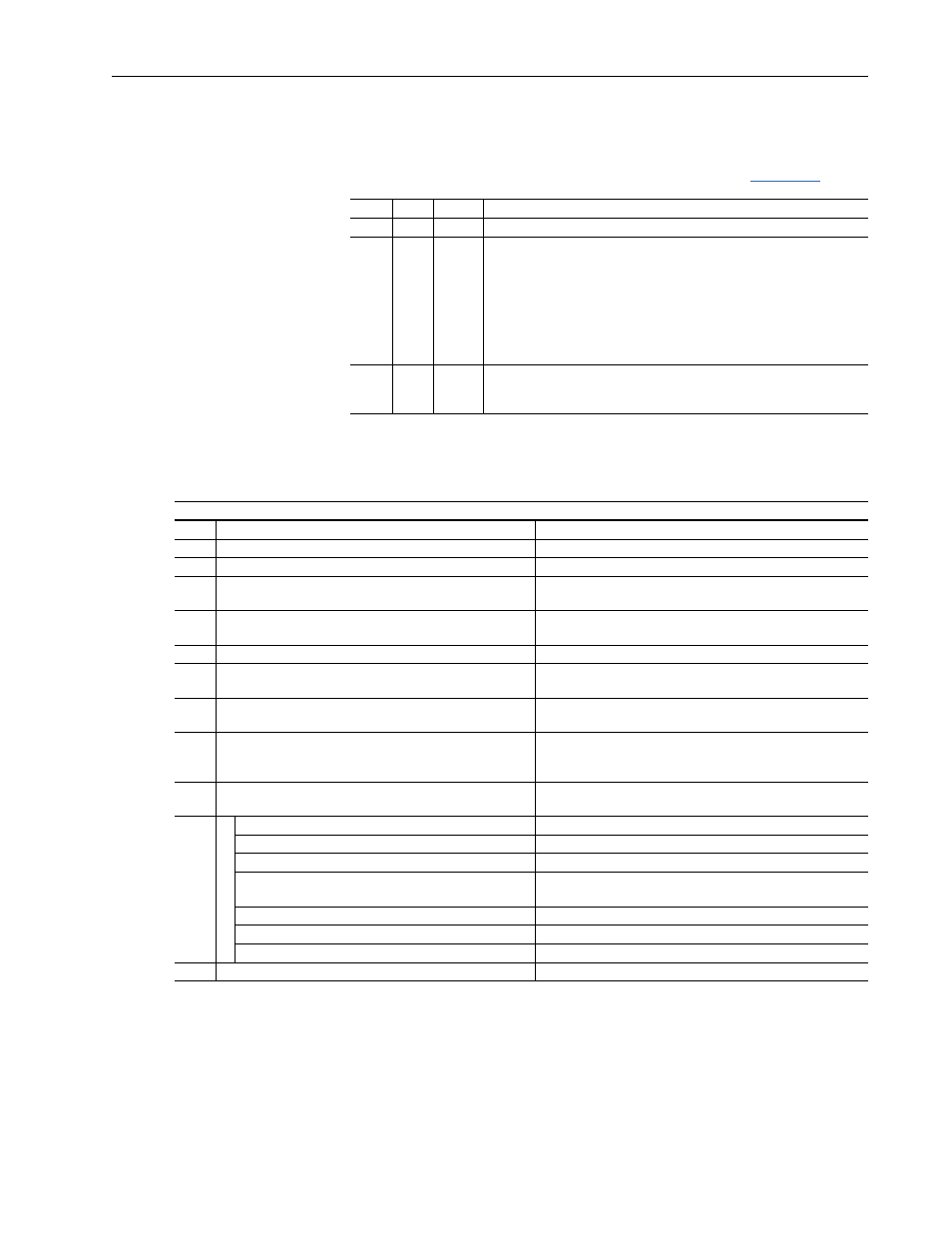

Table 4.B Common Causes of a Pre-Start Alarm

Name Color State

Description

Power Green Steady

Indicates when precharge board power supply is operational

Alarm Yellow Flashing

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Number in “[ ]” indicates flashes and associated alarm

(1)

:

Low line voltage (<90%).

Very low line voltage (<50%).

Low phase (one phase <80% of line voltage).

Frequency out of range or asymmetry (line sync failed).

Low DC bus voltage (triggers ride-through operation).

Input frequency momentarily out of range (40-65 Hz).

DC bus short circuit detection active.

(1)

An alarm condition automatically resets when the condition no longer exists

Fault

Red

Flashing

[2]

[4]

Number in “[ ]” indicates flashes and associated fault

(2)

:

DC bus short (Udc <2% after 20 ms).

Line sync failed or low line (Uac <50% Unom).

(2)

A fault indicates a malfunction that must be corrected and can only be reset after cycling power.

Examine Parameter 156 [Run Inhibit Status]

Bit

Description

Action

1

No power is present at the Enable Terminal TB1- T7

Apply the enable

2, 3, 4 A stop command is being issued

Close all stop inputs

5

Power loss event is in progress, indicating a loss of the AC

input voltage

Restore AC power

6

Data supplied by the power structure EEprom is invalid or

corrupt

Cycle the power. If problem persists, replace the power structure.

7

Flash Update in Progress

Complete Flash Procedures

8

Drive is expecting a Start Edge and is receiving a continuous

signal.

Open all start buttons and remove all start commands

9

Drive is expecting a Jog Edge and is receiving a continuous

signal.

Open all jog buttons and remove all jog commands

10

A conflict exists between the Encoder PPR programming

(Parameter 232 or 242) and the encoder configuration for

edge counts (Parameter 233 or 243, bits 4 & 5).

Verify encoder data and reprogram

11

The drive cannot precharge because a precharge input is

programmed and no signal is present.

Reprogram the input or close the precharge control contact.

12

Dig

ital

Co

nfig

urati

on

Start input configured but stop not configured

Program Par 838-840 to include a stop button, rewire the drive

Run input configured but control options do not match

Program Par 153, Bit 8 to “0” (2 wire control)

Start input configured but control options do not match

Program Par 153, Bit 8 to “1” (3 wire control)

Multiple inputs configured as Start or Run

Reprogram Par 838-840 so multiple starts, multiple runs or any

combination do not exist

Multiple inputs configured as Jog1

Reprogram Par 838-840 so only (1) is set to Jog1

Multiple inputs configured as Jog2

Reprogram Par 838-840 so only (1) is set to Jog2

Multiple inputs configured as Fwd/Rev

Reprogram Par 838-840 so only (1) is set to Fwd/Rev

14

Invalid Feedback Device for Permanent Magnet Motor Control Set Par 222 to Value 5 (FB Opt Port0)