Rockwell Automation 20D PowerFlex 700S Drive Ph I Control, Frames 1...11 User Manual

Page 39

Installation/Wiring

1-25

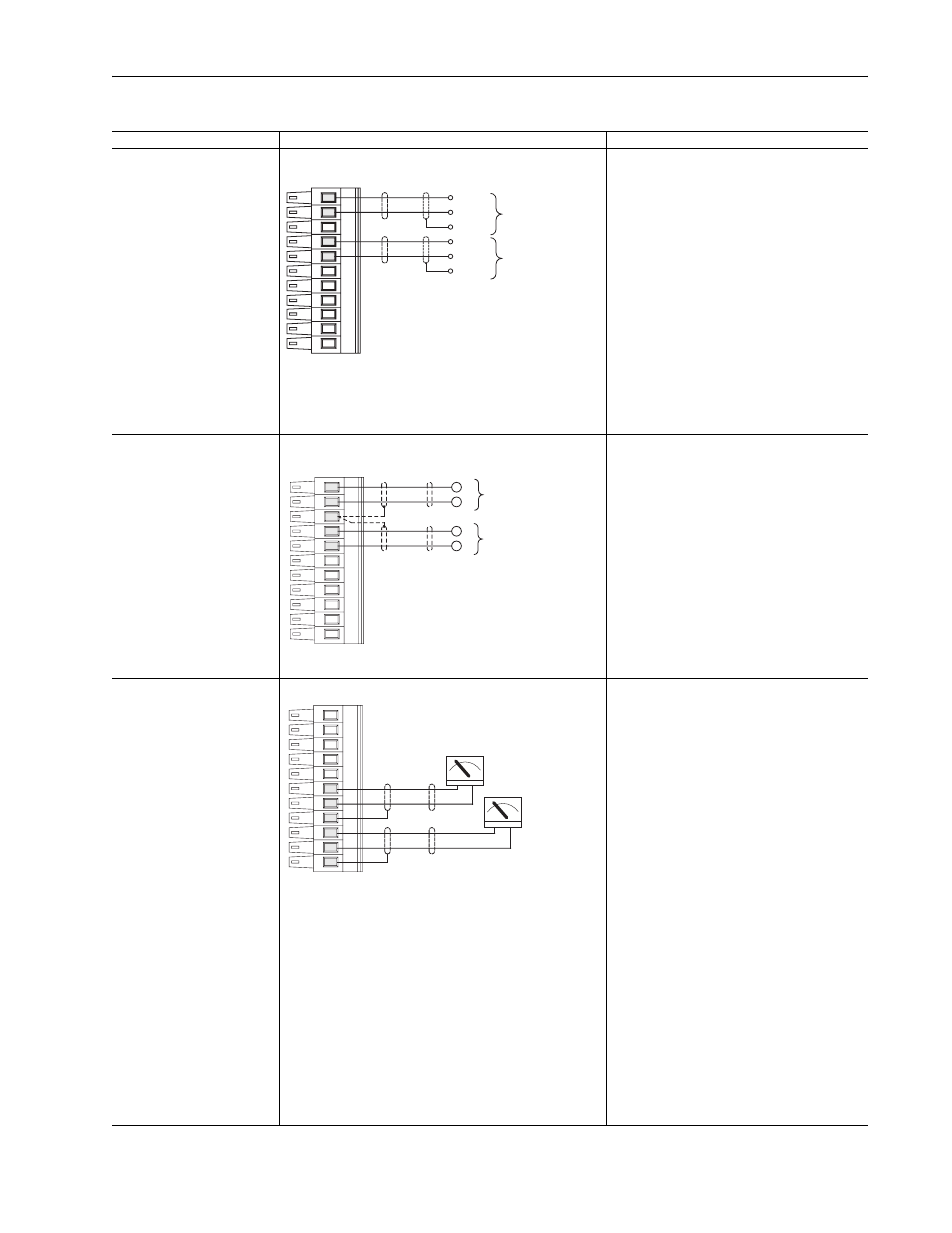

Table 1.M TB1 - Row B (Bottom) Wiring Examples

Input/Output

Connection Example

Required Parameter Changes

Analog Inputs

+/-10V DC or +/-1.0V DC

(DIP switch selectable)

Terminate shields at the analog

source if analog common is

available

Used for Speed Reference and

Speed Trim

Analog Inputs for Speed Reference and Speed Trim - shield

terminated at source

Using Analog In1 as 0-10V speed reference

• Adjust Parameter 803 [Anlg In1 Offset] so that

the minimum analog signal creates the minimum

speed reference (if the minimum input is 0V DC

and the minimum speed reference is zero, enter

a value of zero)

• Adjust the Parameter 802 [Anlg In1 Scale] so

that the maximum analog signal creates the

maximum speed reference (if the maximum

input is 10V DC and the maximum speed

reference is motor base speed, enter a value of

0.1)

• Send the data to the Speed Reference

parameter

Par 10 [Speed Ref 1] (the destination) linked to

Par 800 [Anlg In1 Data] (the source)

• Select Ref 1 as the active speed ref Par 16

[Speed Ref Sel] = 1

• Par 153 [Control Options], bit 0 = 0 Unipolar

Speed Reference”

Analog Outputs

+/-10V DC or +/-1.0V DC

Used to drive analog meters

displaying speed and current

Analog Inputs for Speed Reference and Speed Trim - shield

terminated at drive

Using Analog In2 as -10 to +10V speed trim @

10%:

• Adjust Parameter 809 [Anlg In2 Offset] so that

the minimum analog signal creates the minimum

speed trim (if the minimum input is 0V DC and

the minimum trim is zero, enter a value of zero)

• Adjust Parameter 808 [Anlg In2 Scale] so that

the maximum analog signal creates the

maximum speed trim (if the maximum input is

10V DC and the maximum speed trim is 10%,

enter a value of 0.01)

• Send the data to the speed Reference

parameter

Par 12 [Speed Ref 2] (the destination) linked to

Par 806 [Anlg In2 Data] (the source)

• Select Ref 1 as the active speed ref and Ref 2

as trim [Speed Ref Sel] = 3

Analog Outputs

+/-10V DC

Analog Outputs Indicating Motor Speed and Motor Current

Using Analog Out 1, -10V to +10V to meter

Motor RPM and direction:

• Adjust Parameter 812 [Anlg Out1 Offset] so that

minimum speed creates a minimum signal (if the

minimum speed is zero and the minimum signal

is zero, enter a zero)

• Adjust Parameter 817 [Anlg Out1 Scale] so that

the maximum speed creates a maximum signal

(if the maximum speed is 100% of motor base

speed and the maximum signal is 10V DC, enter

a value of 0.1)

• Send the data to the Analog Output

Par 815 [Anlg Out1 Real] (the destination) linked

to Par 300 [Motor Spd Fdbk] (the source)

Using Analog Out 2, -10V to +10V to meter

Motor Current

• Adjust Parameter 813 [Anlg Out2 Offset] so that

minimum current creates a minimum signal (if

the minimum current is zero and the minimum

signal is zero, enter a zero)

• Adjust Parameter 822 [Anlg Out2 Scale] so that

the maximum current creates a maximum signal

(if the maximum current is 200% of motor NP

FLA and the maximum signal is 10V DC, enter a

value of 2.0)

• Send the data to the Analog Output

Par 820 [Anlg Out2 Real] (the destination) linked

to Par 308 [Output Current] (the source)

• Scale the Output to the source parameter

Par 822 [Anlg Out2 Scale] = xx (Par2 [Motor NP

FLA]/10V Output

11

10

8

7

-

+

Common

(Return)

Analog Input #1

Speed

Reference

-

+

Common

(Return)

Analog Input #2

Speed

Trim

11

10

8

7

-

+

-

+

9

Speed Reference

0-10V dc = 0-100%

of Motor Base Speed

Speed Trim

0-10V dc = 0-10%

Trim

+

-

+

-

2

3

4

5

6

1

Output #1

Motor

Speed

Output #2

Motor

Current