Maple Systems 5000HD Series User Manual

Page 90

84

EZwarePlus Programming Manual

1010-1015, Rev. 03

Change Window

This causes the HMI to close the currently-displayed Base Window, and display the Base Window whose

number is in the specified Trigger address.

The Change Window action occurs only when the HMI detects a change in the value of the specified Trigger

Address.

After the window is changed, the HMI will write the number of the newly-displayed window to

(Trigger Address +1).

Write data to PLC (current base window)

When the HMI initializes, and when the Base Window changes (for any reason), the number of the new Base

Window is written to the PLC Register specified by the Trigger address.

General PLC Control

Executes a data transfer of up to 32 words from the HMI to the PLC or from the PLC to the HMI when the

value in the Trigger Address is set to a valid operation code. After the operation is complete, the HMI sets the

value in the Trigger address to 0. A total of four values are needed to configure the General PLC Control

attribute.

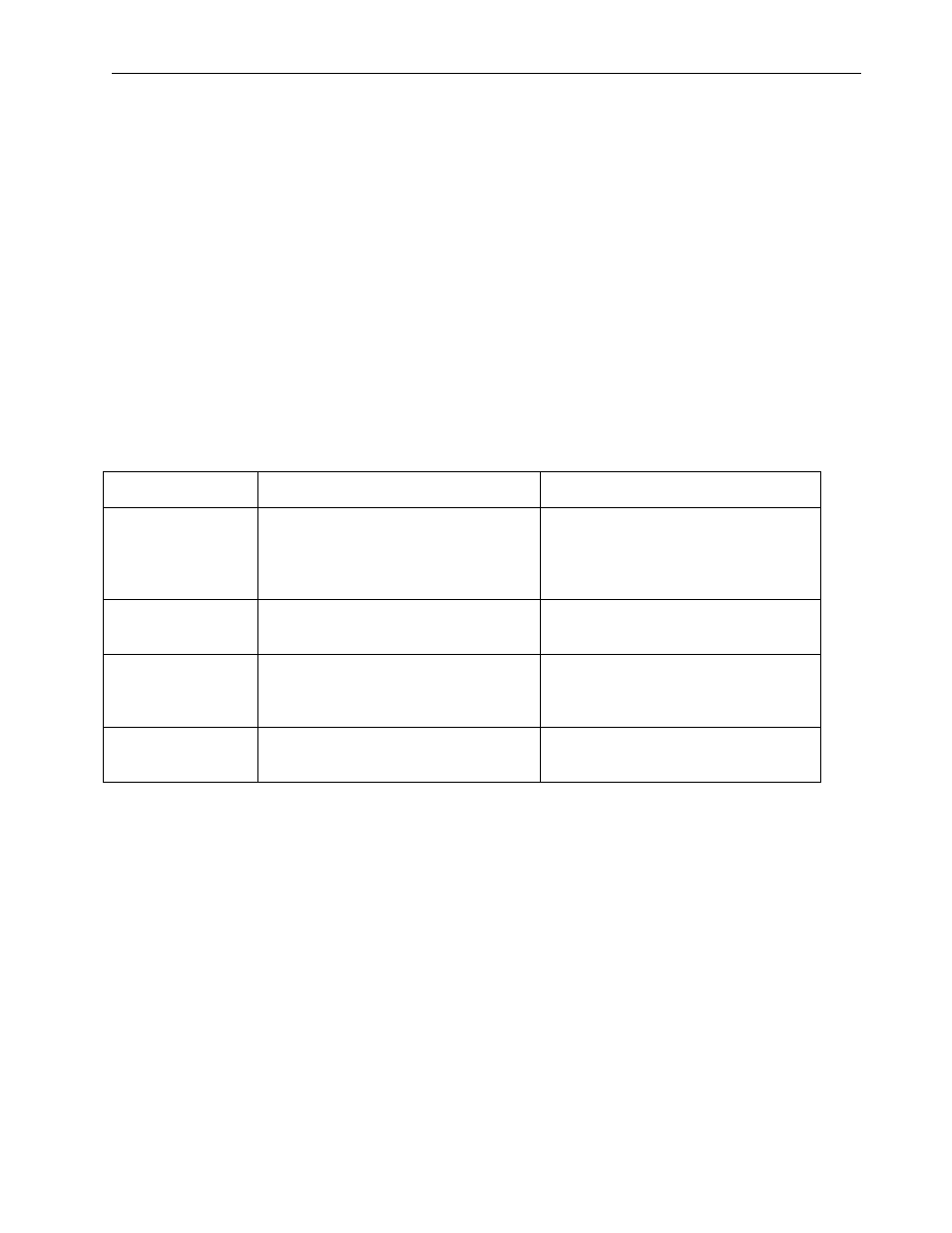

Address

Function

Details

Trigger address

Operation code. Valid codes are 1, 2, 3, 4.

The Trigger address is set to 0 by the HMI

when the transfer is complete.

1. PLC to HMI: RW (recipe words)

2. PLC to HMI: LW (local words)

3. HMI to PLC: RW to PLC

4. HMI to PLC: LW to PLC

Trigger address + 1

Number of words to transfer

(32 words maximum)

The number of words to transfer from

the PLC to the HMI or HMI to PLC.

Trigger address + 2

PLC Data Address Offset

The Address Offset (from the Trigger

address + 4) at which the transfer of data

to/from the PLC will start.

Trigger address + 3

HMI Data Address Offset

The Address Offset at which the transfer

of data to/from the HMI will start.

Note:

The HMI will transfer data to/from the Device Type specified by the Trigger address.

It is recommended that the data in (Trigger Addr + 1), (Trigger Addr +2), and (Trigger Addr +3) be set before

writing the Operation Code to (Trigger Addr).

Backlight Control (Write Back)

Allows the PLC to control the HMI’s backlight via the bit specified in the Trigger address. Once the requested

operation has been performed, the HMI will reset the bit.

Note: The PLC Control Object may be configured with two Backlight Control (Write Back) items, with different

bits for the On and Off control. The backlight can then be controlled directly from the PLC.

Backlight Control

Operates the same as the Backlight Control (Write back) attribute described above, but the HMI will not reset

the bit specified in the Trigger address.